Cleanable injection mold

An injection mold and punch technology, applied in the field of mold processing, can solve problems such as dust, and achieve the effect of convenient cleaning, improving work efficiency and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

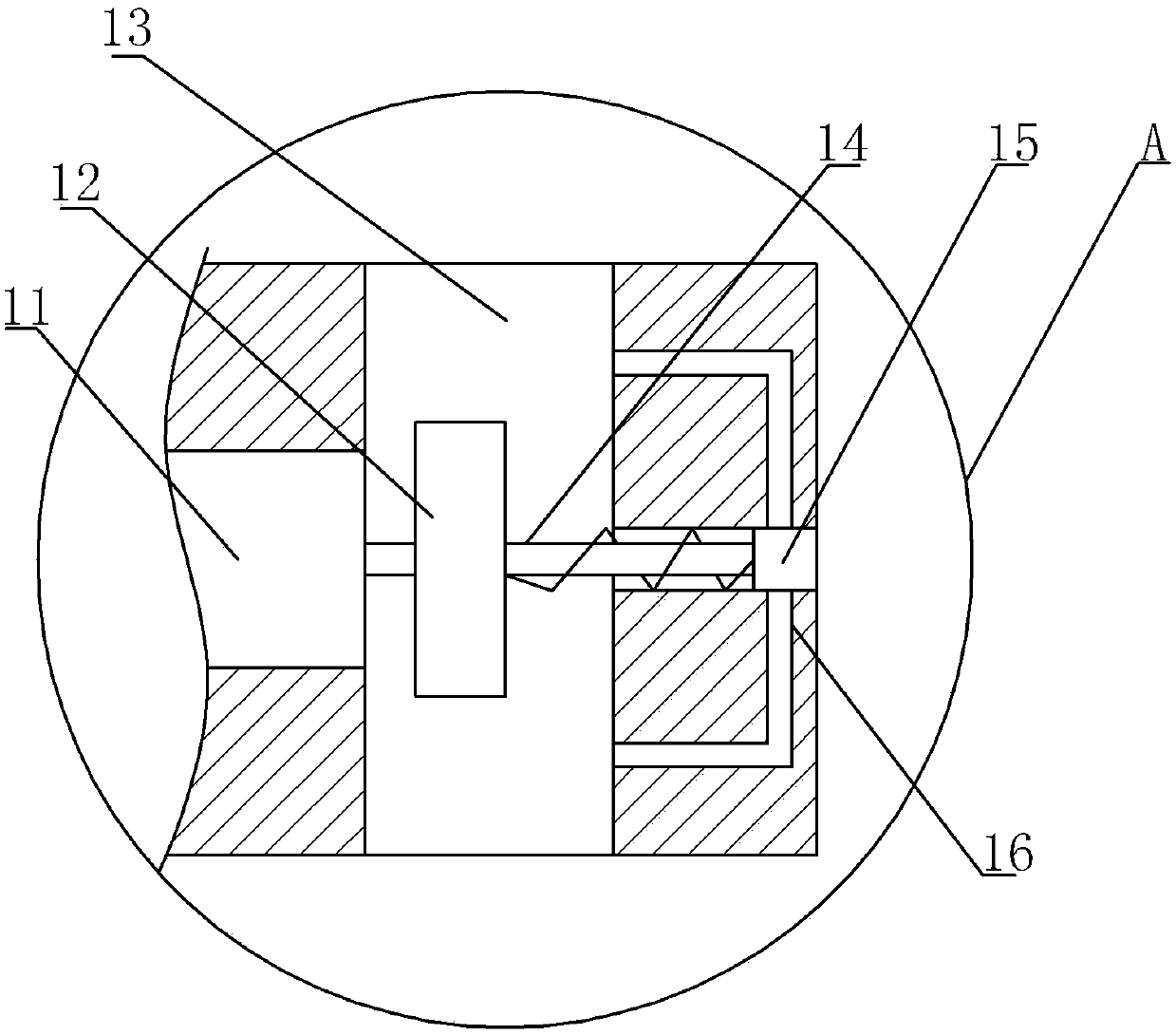

[0021] as attached figure 1 And attached figure 2 As shown, a cleanable injection mold includes an upper mold and a lower mold. The upper mold is a punch 1, and the lower mold is a die 2. When the punch 1 and the die 2 are engaged, the gap between the punch 1 and the die 2 is A molding cavity is formed between them, and the punch 1 is provided with an injection channel communicating with the molding cavity. Use the injection molding machine to inject plastic melt into the molding cavity through the injection channel.

[0022] The bottom of the die 2 is provided with a cooling chamber, the cooling chamber is provided with a slide plate 6 slidingly connected with the die 2, the slide plate 6 can slide vertically on the die 2 and the slide plate 6 closes the cooling chamber, the slide plate 6 and the die 2 A seal is provided at the sliding connection to seal the cooling chamber. The bottom of the slide plate 6 is provided with a clip spring 5 with one end fixed on the slide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com