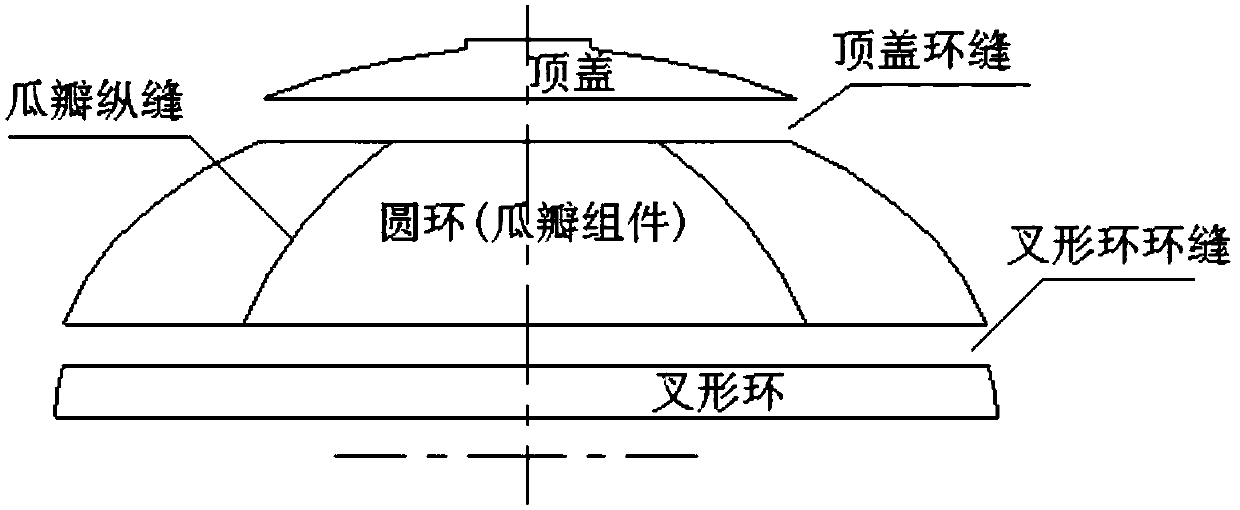

Tool and method for matching circular ring with transitional ring at bottom of rocket storage box

A transition ring and circular ring technology is applied in the field of matching tooling between the bottom ring of the rocket tank and the transition ring. Good, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0102] (1) The mold tire assembly 5 is hoisted on the rotary platform, and the surface impurities of the mold tire 29 are blown off with low-pressure air, and then the welding backing plate is wiped with alcohol to ensure that there are no oil stains and other metal impurities on the welding backing plate;

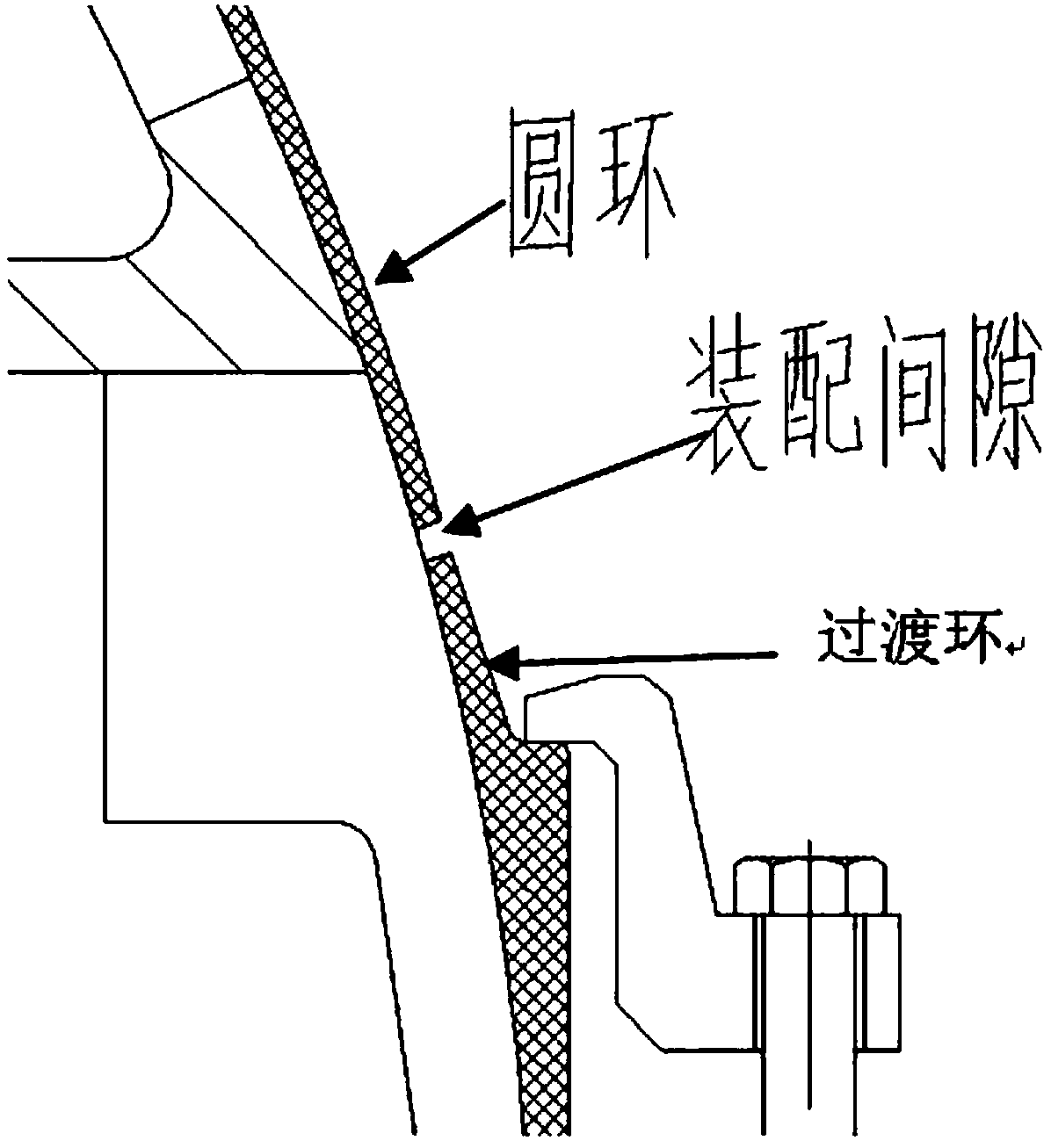

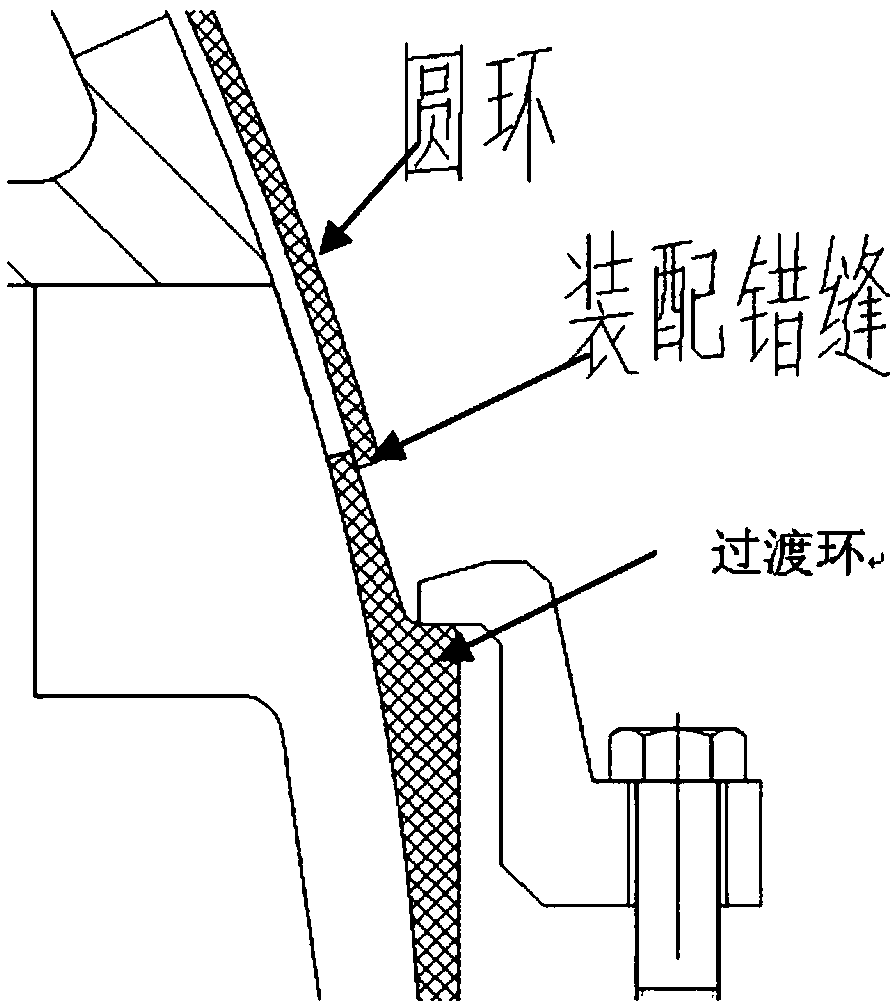

[0103] (2) Lift the transition ring and the transition ring pressure ring 6, and install them on the mold tire 29 and the support platform 28, adjust the bolts of the transition ring pressure ring 6 and the support platform 28 with a wrench, so that the transition ring pressure ring 6 carries the transition ring Drop, let the small end of the transition ring contact with the welding backing plate 30. Place the height gauge on the reference plane of the support platform 28, measure the distance from the small end of the transition ring to the reference plane of the support platform 28 at 8 points uniformly in the circumferential direction with the height gauge, and measure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com