Permeability measuring device and method of hydrate-contained sediments under three-axis stress conditions

A triaxial stress and hydrate-containing technology, which is applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as high cost, large error, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

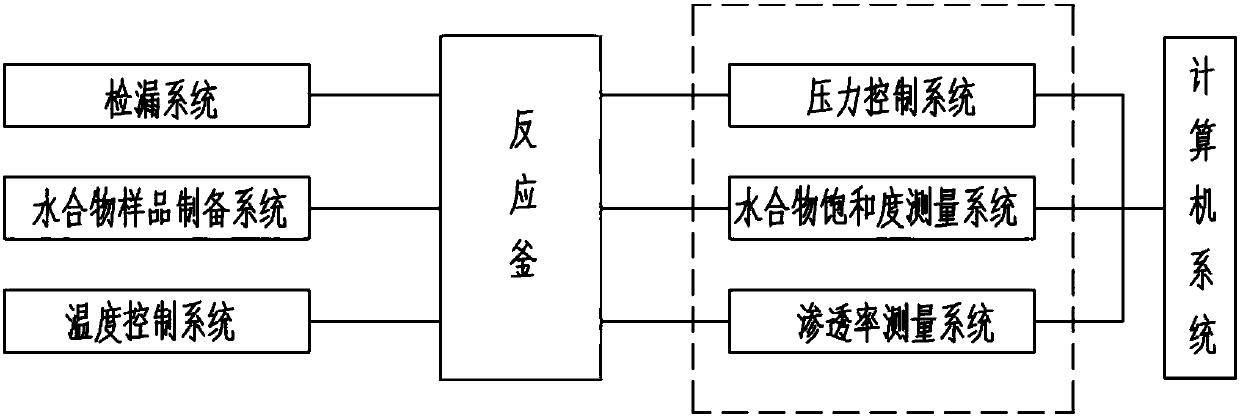

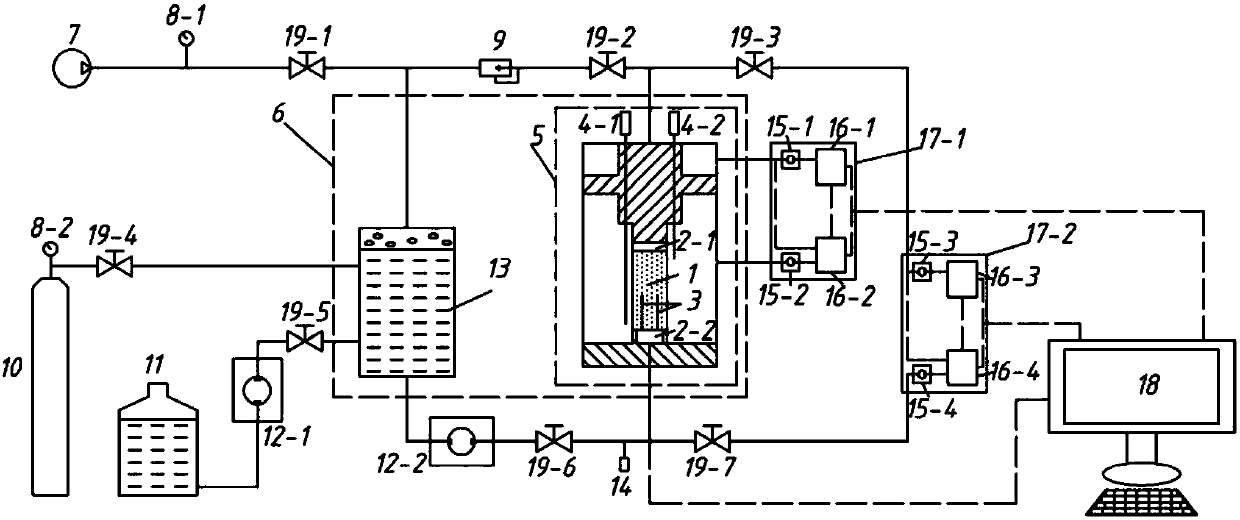

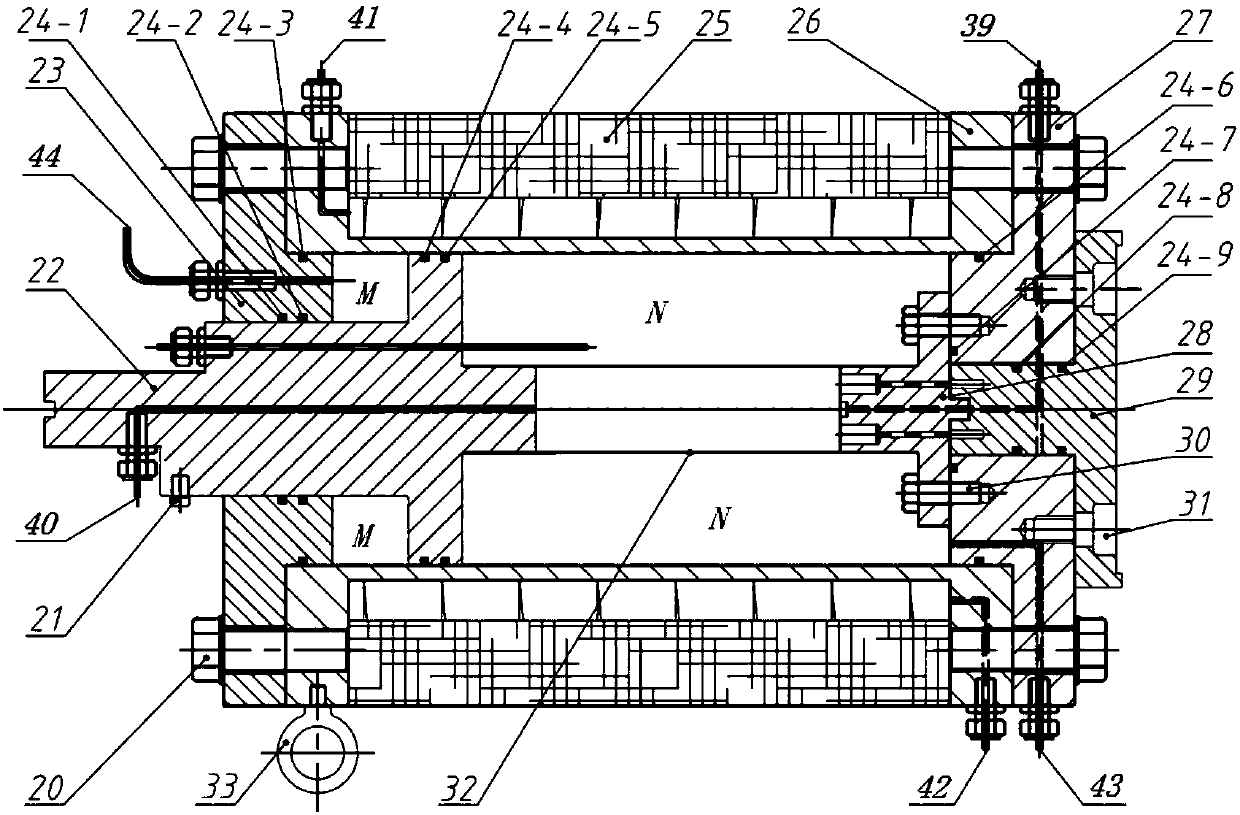

[0050] Example 1, a device for measuring the permeability of hydrate-containing sediments under triaxial stress conditions, refer to figure 1 , including a reactor, a leak detection system connected to the reactor, a temperature control system, a pressure control system, a hydrate sample preparation system, a hydrate saturation measurement system, and a permeability measurement system. In order to facilitate sample loading and subsequent disassembly of the reactor, It also includes special tooling for the reactor, in which the pressure control system, hydrate saturation measurement system and permeability measurement system are all connected to the computer. The reactor is used to simulate the temperature, pressure and other parameters of the hydrate reservoir. The temperature control system provides the reactor with the temperature required for the simulation experiment. The axial pressure and the confining pressure are applied synchronously by connecting the pressure control ...

Embodiment 2

[0060] Embodiment 2, based on the permeability measurement device proposed in Embodiment 1, this embodiment proposes a method for measuring the permeability of hydrate-containing sediments under triaxial stress conditions, including the following steps:

[0061] (1) Check the air tightness of the device;

[0062] Before the installation of sample 1, replace the experimental sample with a special φ39.1×80mm rubber sample, install the reaction kettle, inject a pressure of 10MPa into the kettle body, check whether the pressure leaks, check whether the sealing rings and vulnerable parts are intact, the key points Check the dynamic seal between the piston cylinder 22 and the reaction kettle cavity 26, and the standard for judging that each sealing point is leak-proof is that the internal pressure of the kettle body remains constant for more than 10 hours. Check the airtightness by pumping a certain amount of pressure to the whole device through the air pump 7. The standard of good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com