Pipe safety evaluation device and method based on strain detection

A technology for safety evaluation and piping, applied to measuring devices, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as cumbersome process and measurement point determination error, and achieve simple and efficient detection scheme and real-time test process visible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

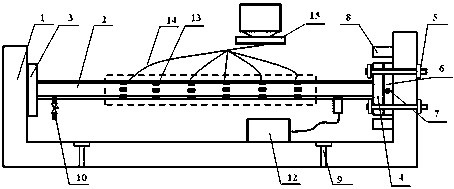

[0043] Embodiment 1, with reference to attached Figure 1-4 , a kind of pipeline safety evaluation device based on strain detection mentioned in the present invention, its technical scheme is: including test bench 1, pipeline 2, pipeline fixing and axial displacement loading device, lateral displacement loading device, pipeline internal pressure loading device, Strain detection and analysis device,

[0044] The left column of the test bench 1 has a plurality of threaded holes, which are connected to the left flange 3 of the pipeline, and the left end of the pipeline 2 is fixed. The right column of the test platform 1 is equipped with a lateral displacement loading device, which is used to adjust and fix the position of the pipeline. In the horizontal position, a plurality of base connection threaded holes 9 are symmetrically opened on the bottom of the test bench 1, so that the test bench is fixedly connected to the foundation;

[0045] The pipeline 2 is a stainless steel sea...

Embodiment 2

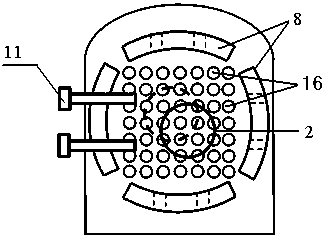

[0064] Embodiment 2, with reference to attached Figure 5 , the difference from Embodiment 1 is that the reinforcing ribs 8 for radial displacement of the present invention are provided with four sets of ribs of elongated structure, which are respectively fixed on the upper, lower, left, and right sides of the inner wall of the right flange 4, and surround multiple sets of transverse ribs. On the outside of the threaded hole 16 for position fixing, the cross-section forms a square structure, and one or more threaded holes are provided on each reinforcing rib 8 for radial displacement, which are used to install the lateral displacement loading bolt 11 of the pipeline. The present invention can also To achieve the lateral displacement of the pipeline.

Embodiment 3

[0065] Embodiment 3, with reference to attached Image 6 , the difference from Embodiment 1 is that the ribs 8 for radial displacement of the present invention are composed of two sets of ribs with elongated structures and two sets of ribs with arc structures, which are fixed on the right flange 4 respectively. The upper, lower, left, and right sides of the inner wall are surrounded by multiple groups of threaded holes 16 for lateral position fixing. The cross-section forms a square structure, and one or more threaded holes are provided on each reinforcing rib 8 for radial displacement, which are used for installing pipelines. The lateral displacement loads the bolt 11, and the present invention can also realize the lateral displacement of the pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com