Real-time online monitoring system for wear conditions of brake pads of motor train unit

A technology for monitoring the wear and tear of the system, applied in the direction of brake safety systems, brake components, brakes, etc., can solve problems such as brake failure, car crash and death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] see Figure 4 , the present invention discloses a real-time on-line monitoring system for brake pad wear of EMUs. The monitoring system includes: several displacement sensors D, several spoke / axle front-end machines C, several EMU carriage monitoring extensions B, and EMU monitoring hosts a.

[0063] The EMU monitoring host A is connected to each EMU carriage monitoring extension B, the EMU carriage monitoring extension B is connected to the corresponding spoke / shaft front-end unit C, and the spoke / shaft front-end unit C is connected to the corresponding displacement sensor D.

[0064] One distance measuring sensor is installed on the left and right sides of each wheel disc brake and axle disc brake caliper. When the EMU implements air braking, the distance sensor installed on the brake caliper and the The brake disc is close, and the distance between the brake caliper and the brake disc is measured. The thickness of the brake pad is 35mm when it is not worn, and the w...

Embodiment 2

[0072] A real-time on-line monitoring system for brake pad wear of an EMU, the monitoring system comprising: several displacement sensors, several spoke / axle front-end units, several EMU carriage monitoring extensions, and an EMU monitoring host.

[0073] One distance measuring sensor is installed on the left and right sides of each wheel disc brake and axle disc brake caliper. When the EMU implements air braking, the distance sensor installed on the brake caliper and the The brake disc is approached, and the distance between the brake caliper and the brake disc is measured.

[0074] The travel distance measured by the eddy current sensor installed on the brake caliper is compared with the distance of the new brake pads. When it is greater than the set value, the monitoring system will alarm and prompt the driver and maintenance personnel to replace the worn brake pads in time.

Embodiment 3

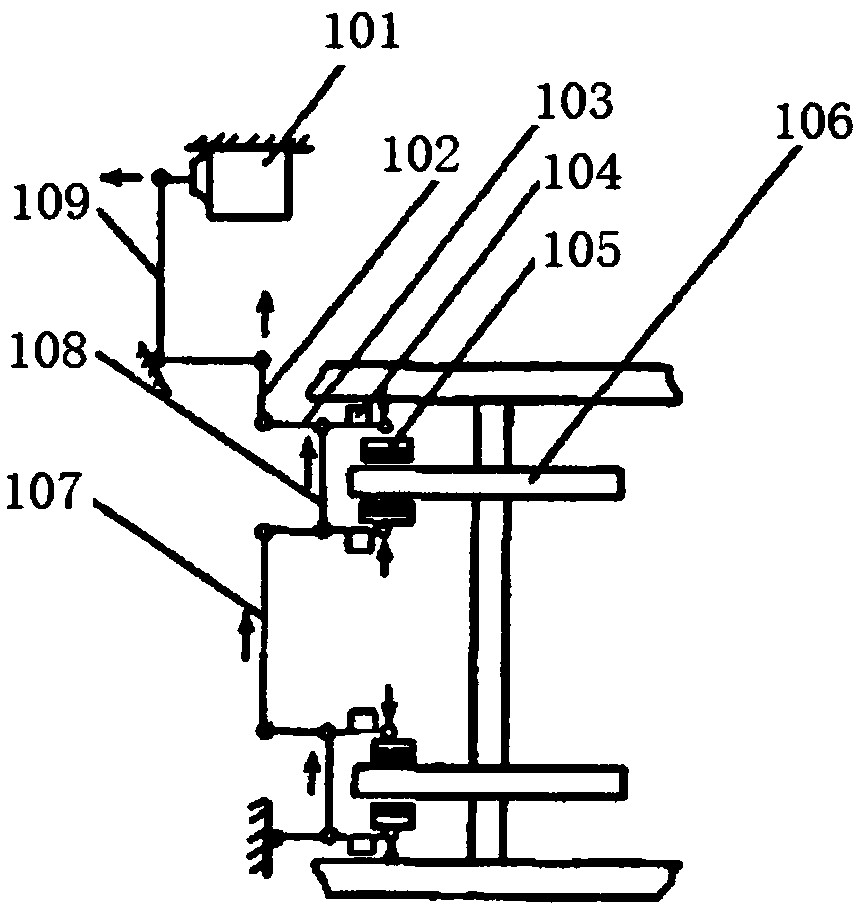

[0076] The EMU brake adopts disc brakes, also known as friction disc brakes. One is to install brake discs on the axle, and the other is to install brake discs on the spokes of the wheels. Generally, it is a cast iron disc or a steel disc. The two brake pads made of synthetic materials are pressed tightly against the side of the brake disc with a brake caliper. The braking force is generated through friction, and the kinetic energy of the train is converted into heat energy, which is dissipated in the atmosphere. The structure of the EMU brake machine is as follows: figure 1 As shown, wherein 101 is a brake cylinder, 102 is a pull ring, 103 is a horizontal lever, 104 is a relief spring, 105 is a brake pad, 106 is a brake disc, 107 is an intermediate pull rod, 108 is a horizontal lever pull rod, and 109 is a rotation arm.

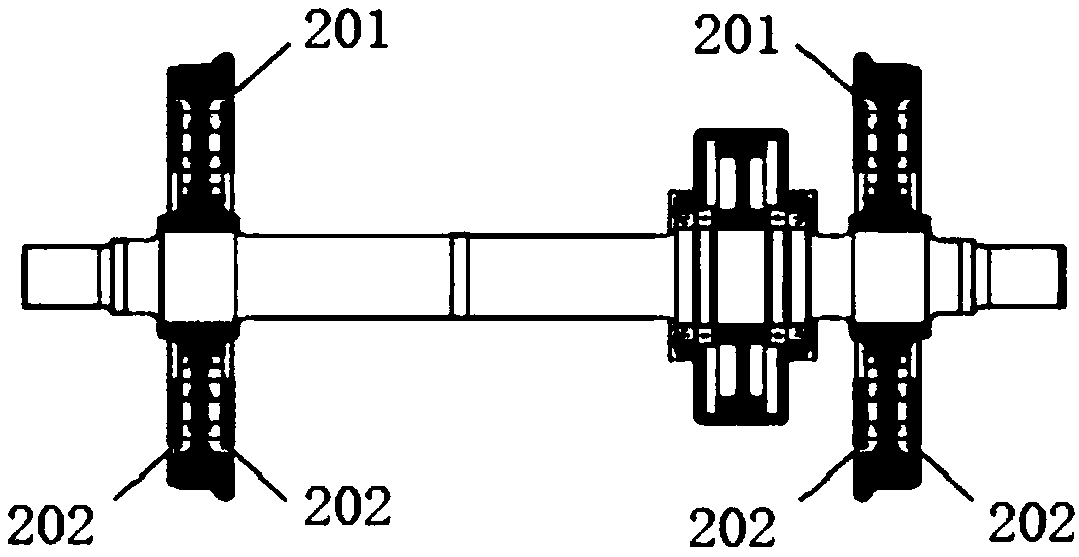

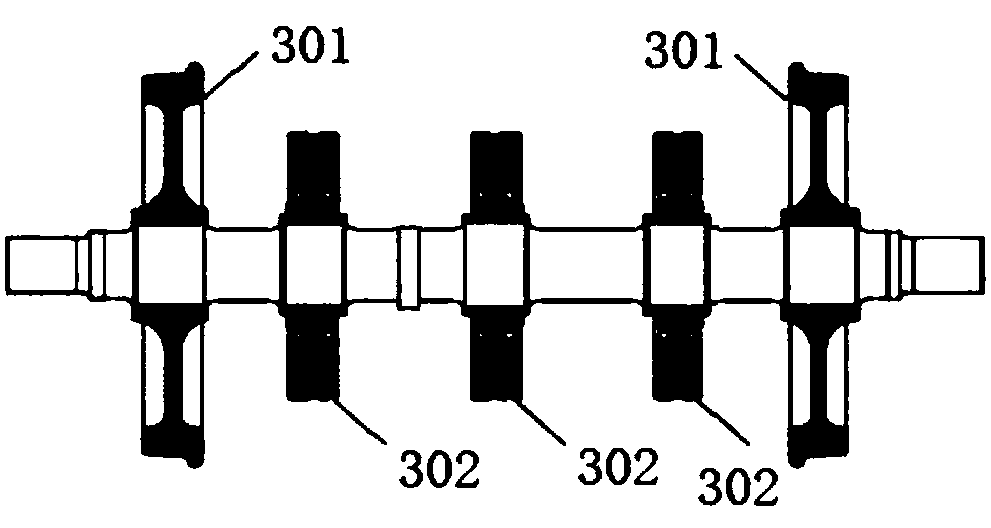

[0077] The brake mode of the EMU is: two sets of wheel-disc brake devices for each axle of the power car (see figure 2 ), EMU trailer three sets of axle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com