An anti-rust and anti-corrosion adhesive paste for steel structures

A technology for corroding adhesives and structures, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of limited physical isolation performance, coarse grains, high temperature resistance, aging resistance, limited hardness and impact resistance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

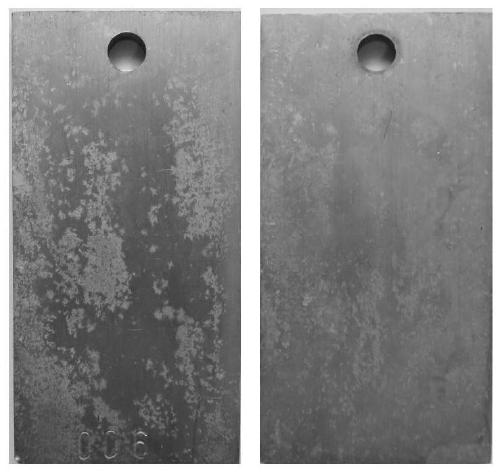

[0021] The composition by weight percentage is: 55% of polybutene, 10% of organic bentonite, 3.5% of carboxymethyl chitosan, 0.2% of titanium dioxide, 21% of mica powder, 0.3% of graphene and 10% of zinc powder. The number of graphene powder layers is 4 layers, and the particle size is 8 μm. Zinc powder is spherical high-purity zinc powder with a specification of 800 mesh. Apply the obtained anti-rust and anti-corrosion adhesive paste to a Q235 carbon steel test piece with a size of 50×25×3mm, and remove the corrosion products after 30 days of salt spray test (see figure 1 ). Depend on figure 1 It can be seen that there are corrosion spots on the surface of the test piece, but the corrosion pits are relatively shallow, indicating that the corrosion is slight, and the anti-rust and anti-corrosion adhesive paste has a certain protective effect.

Embodiment 2

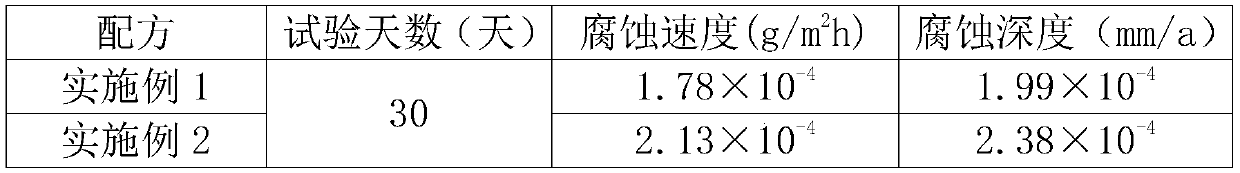

[0023] The composition by weight percentage is: 50% of polybutene, 9% of organic bentonite, 5% of carboxymethyl chitosan, 0.5% of titanium dioxide, 20% of mica powder, 0.5% of graphene and 15% of zinc powder. The number of graphene powder layers is 4 layers, and the particle size is 8 μm. Zinc powder is spherical high-purity zinc powder with a specification of 800 mesh. Apply the obtained anti-rust and anti-corrosion adhesive paste to a Q235 carbon steel test piece with a size of 50×25×3mm, and remove the corrosion products after 30 days of salt spray test (see figure 2 ). Depend on figure 2 It can be seen that, compared with Example 1, the surface corrosion of the test piece of Example 2 is lighter, indicating that the anti-rust and anti-corrosion adhesive paste of Example 2 has a better protective effect.

[0024] Adopt Q235 carbon steel salt spray hanging piece experiment and the anticorrosion effect of macroscopic appearance measurement embodiment, as follows (referri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com