Whole plant waste water zero-discharge system

A zero-discharge, waste water technology, applied in water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Problems such as high equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

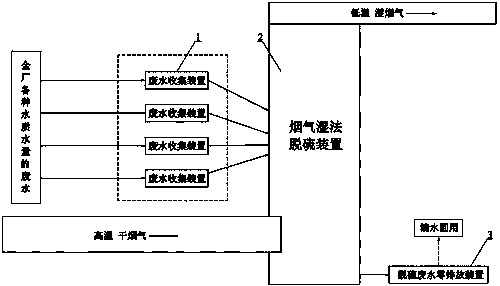

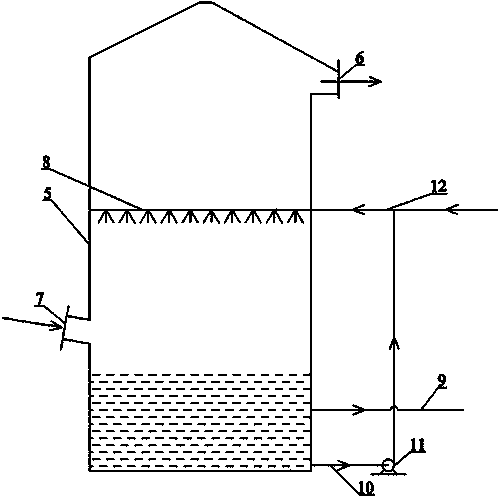

[0031] A zero-discharge system for whole plant wastewater, such as figure 1 , figure 2 As shown, it includes a waste water collection device 1 for collecting waste water from the whole plant, a flue gas wet desulfurization device 2 and a desulfurization wastewater zero discharge device 3, and the discharge pipe of the waste water collection device 1 is connected to the flue gas wet desulfurization device 2 through pipelines , the flue gas wet desulfurization device 2 is used to discharge the desulfurization waste water discharge pipe through the pipeline to connect the desulfurization waste water zero discharge device 3 . According to statistics, the evaporated water in the wastewater accounts for 60-80% of the total amount of the original wastewater.

[0032] Therefore, the waste water collection device 1 can change non-regular drainage into regular drainage to control the amount of water entering the flue gas wet desulfurization device 2 to be a stable and continuous amoun...

Embodiment 2

[0052] A system for zero discharge of waste water in the whole plant, its structure is the same as the zero discharge system of waste water in the whole plant described in embodiment 1, and the difference between it and the zero discharge system of waste water in the whole plant described in embodiment 1 is that, as Figure 6 , Figure 7 As shown, between the waste water collection device 1 and the flue gas wet desulfurization device 2, there is also a waste water cascade utilization reduction pretreatment device 4, and the discharge pipe of the waste water collection device 1 is connected to the waste water cascade utilization reduction through a pipeline. The pretreatment device 4 and the waste water cascade are connected to the flue gas wet desulfurization device 2 through pipelines using the discharge pipe of the volume reduction pretreatment device 4 . Preferably, the waste water enters the waste water cascade according to the set flow rate and flow rate and uses the redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com