Method and system for realizing zero discharge of whole factory wastewater

A zero-discharge, waste water technology, applied in the direction of separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve the difficulties of intermittent large-flow drainage, high equipment investment and operating costs, and high-salt waste water treatment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

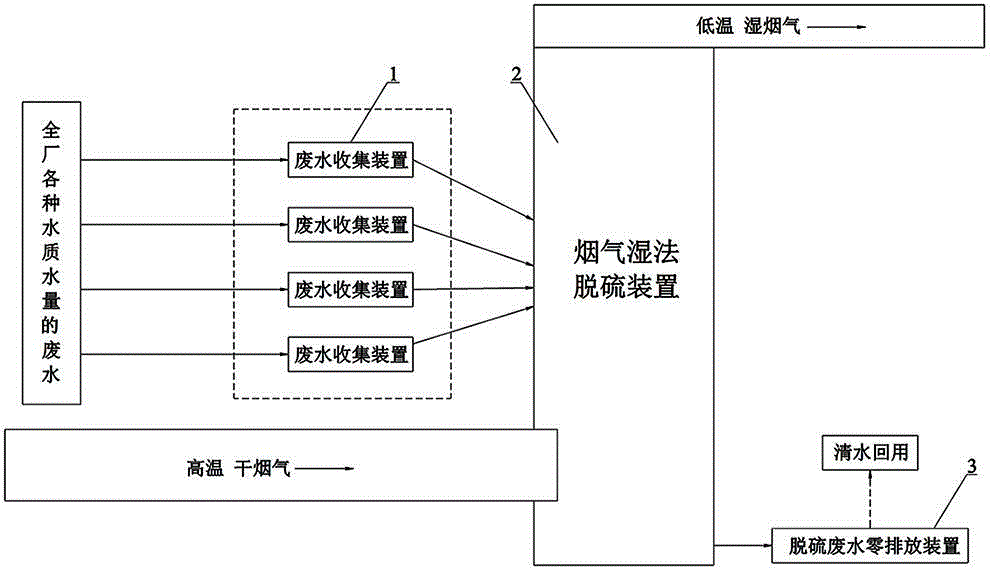

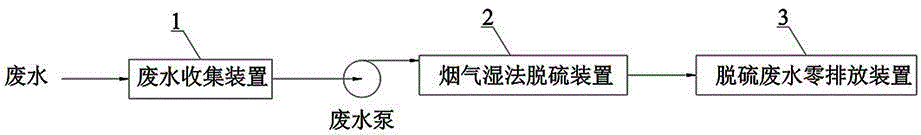

[0047] Such as figure 1 , figure 2 As shown, a method for zero discharge of waste water in the whole plant includes the following steps:

[0048] S1. The wastewater of the whole plant enters the wastewater collection device 1;

[0049] S2. The waste water enters the flue gas wet desulfurization device 2 from the waste water collection device 1;

[0050] S3. The high-temperature dry flue gas enters the flue gas wet desulfurization device 2;

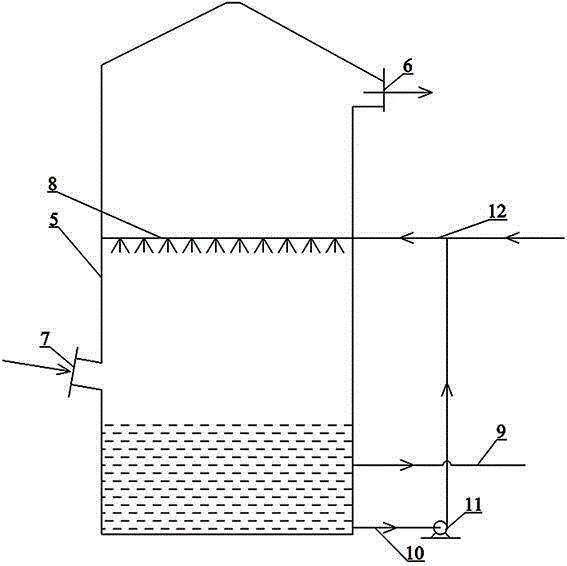

[0051] S4. High-temperature dry flue gas and waste water are in heat exchange contact in the wet flue gas desulfurization device 2, and part of the water in the waste water evaporates to humidify the flue gas and is discharged from the top of the wet flue gas desulfurization device 2; Water accounts for 60-80% of the total amount of raw wastewater;

[0052] S5. The waste water is concentrated after being in contact with the hot flue gas, and discharged together with the desulfurization waste water from the flue gas wet desulfurization...

Embodiment 2

[0068] A method for zero discharge of waste water in the whole plant, such as Image 6 , Figure 7 As shown, its steps are the same as the method for zero discharge of whole plant waste water described in Example 1, and the difference with the method for zero discharge of whole plant waste water described in Example 1 is that in described step S2, after the waste water is collected from the waste water collection device 1 Before entering the wet flue gas desulfurization device 2, it also includes the step of pretreating the wastewater in the wastewater collection device 1, and then leading the pretreated wastewater into the wet flue gas desulfurization device 2. Through the wastewater pretreatment step, part of the water can be recycled and utilized to achieve the purpose of pre-reduction of wastewater cascade utilization, and the remaining concentrated water that cannot be treated enters the flue gas wet desulfurization device 2 . For example, in the pretreatment step, RO re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com