Fully automatic welding equipment for shock absorber piston rod assembly

一种自动焊接、自动焊接机的技术,应用在焊接设备、辅助焊接设备、焊接/切割辅助设备等方向,能够解决悬架弹性变坏、减振器连接件损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

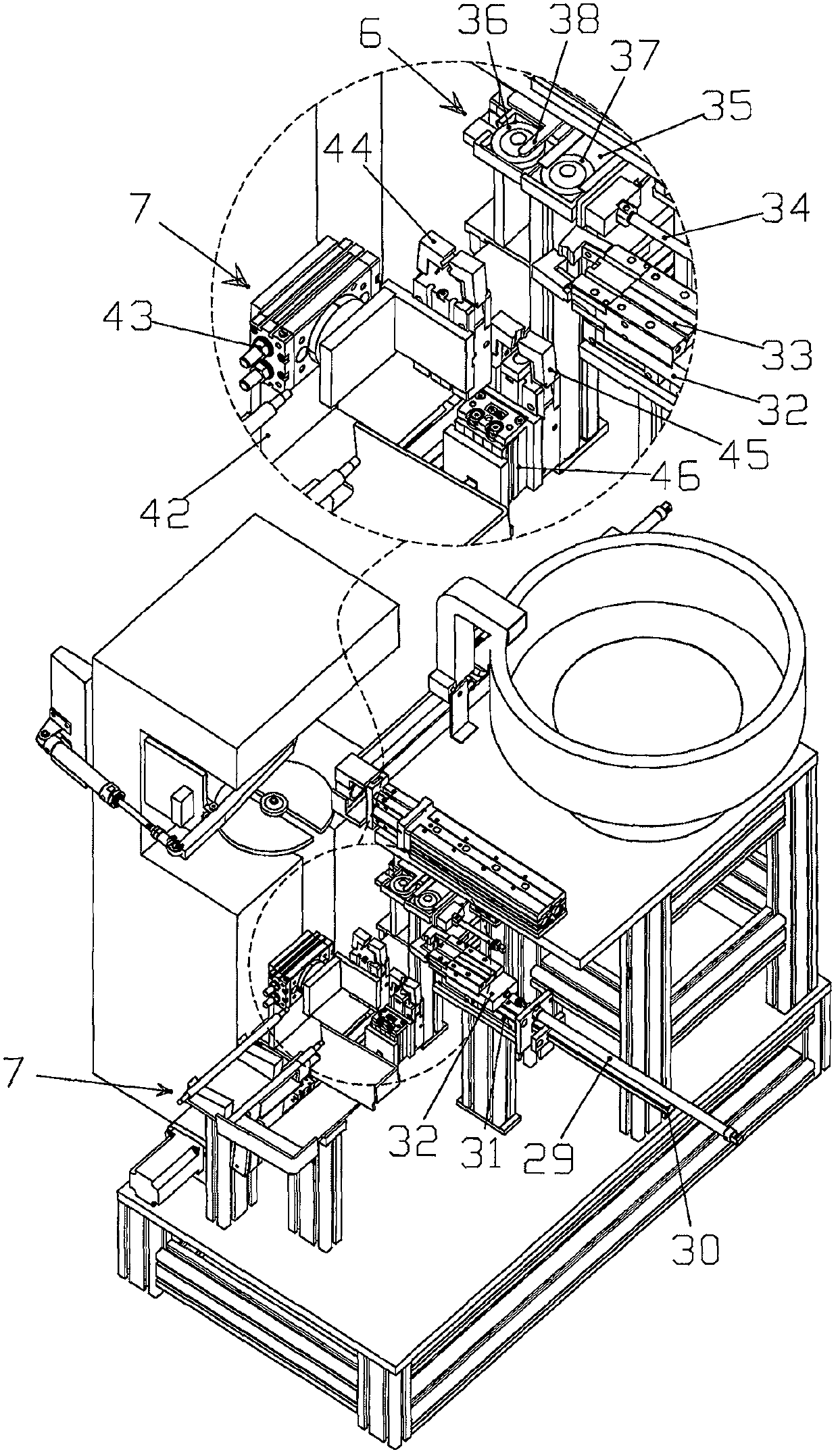

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides a fully automatic welding equipment for shock absorber piston rod assembly. During the automatic production process of shock absorber piston rod assembly, the lifting ring, dust cover and piston rod are combined into a piston rod by welding process. Rod assembly, use the lifting ring feeding mechanism to realize the automatic transportation of the lifting ring, use the dust cover feeding mechanism to realize the automatic transportation of the dust cover, use the piston rod feeding mechanism to realize the automatic transportation of the piston rod, and use the automatic welding machine to connect the lifting ring and the dust cover One-time welding and forming wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com