Energy-saving environmentally-friendly circulating type exhaust gas processing system for paint spraying and paint drying technology

A technology for waste gas treatment, energy saving and environmental protection. It is used in gas treatment, paint spray booth, steam condensation, etc. It can solve the problems of waste of resources, low total amount, incompleteness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

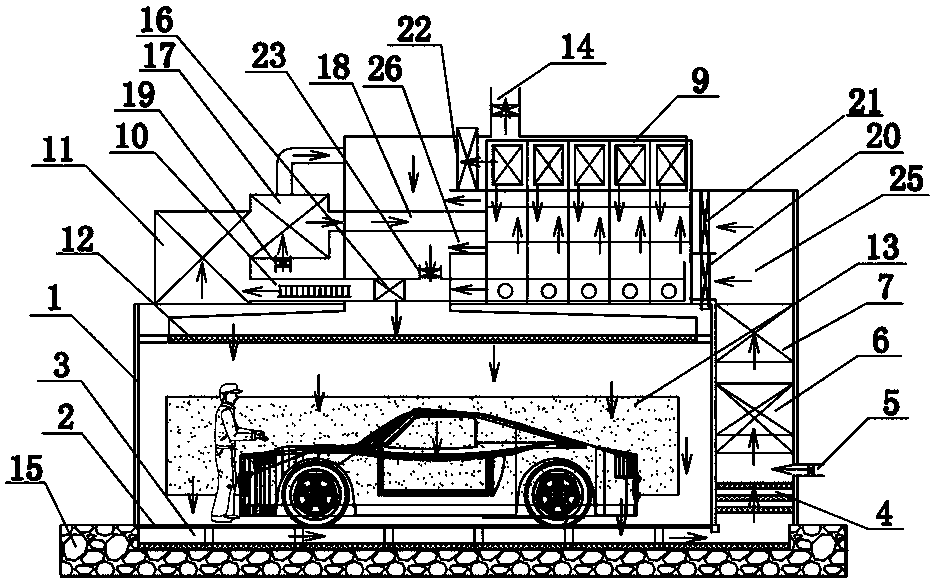

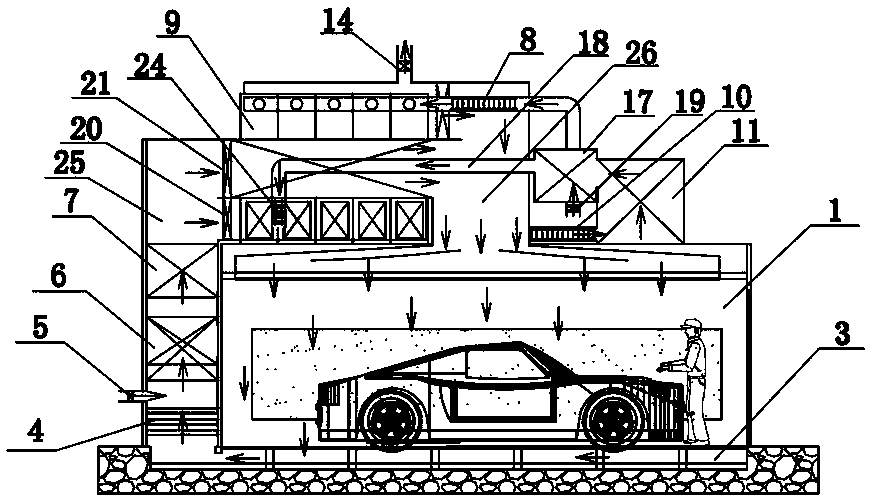

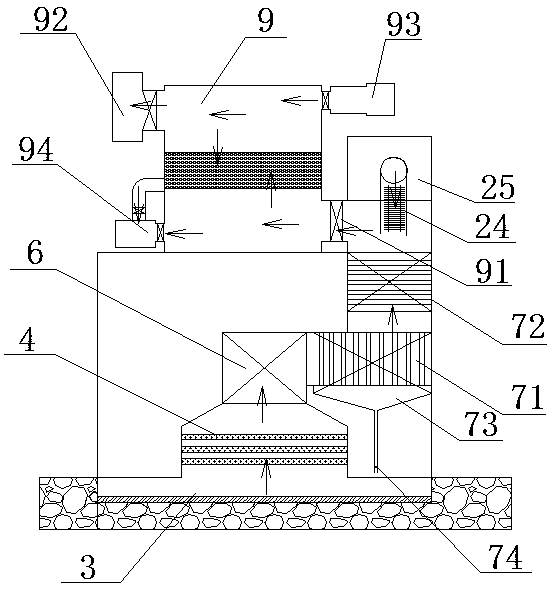

[0034] The energy-saving and environment-friendly circulating exhaust gas treatment system applied to the painting and baking process described in this embodiment is an energy-saving and environmentally friendly circulating exhaust gas treatment system applied to the spraying and baking process, including a spraying room 1 and a circulating exhaust gas treatment unit, a circulating exhaust gas treatment unit The air inlet end of the spraying chamber 1 communicates with the bottom of the spraying chamber 1, and the outlet end of the circulating waste gas treatment unit communicates with the top of the spraying chamber 1. The spraying chamber 1 and the circulating waste gas processing unit form a circulating air duct, and the circulating waste gas processing unit connects the spraying chamber The exhaust gas in 1 is pumped away, and returned to the spray booth 1 after exhaust gas treatment.

[0035]In this embodiment, a circulating exhaust gas treatment unit is used to extract an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com