Compact high-current diode capable of remotely adjusting beam parameters

A technology for remote regulation and diodes, applied in the field of diodes, can solve problems such as low work efficiency and vacuum destruction, and achieve the effects of low production and maintenance costs, reduced diameter, and high diode impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

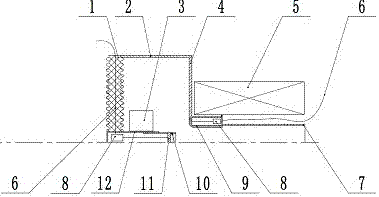

Image

Examples

Embodiment Construction

[0027] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0028] In order to solve the contradiction between diode high impedance adjustment and system miniaturization in the prior art, as well as the problems of low transmission efficiency, realize the impedance adjustment process without destroying the vacuum, and improve the adjustment work efficiency, the present invention discloses a remote adjustable A compact high-current diode with bundle parameters. The diode in the present invention includes a diode outer cylinder made of a conductor, an insulator made of nylon or other insulating materials, a drift tube made of a conductor, a cathode rod made of a conductor, and an adjustable cathode seat made of a conductor. An annular cathode made of a thick circular cathode material, an anode outer cylinder made of a conductor, an adjustable anode inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com