Ceramic xenon discharge lamp filled with lanthanide halide

A technology of lanthanides and halides, which is applied in the field of ceramic xenon discharge lamps, can solve the problems of reducing xenon discharge lamp efficacy and shortening service life, and achieve the effects of maintaining light efficiency, increasing service life and improving light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

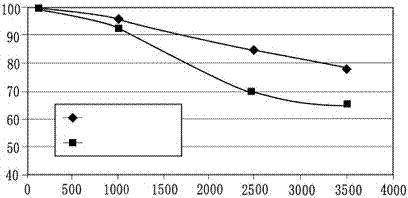

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the scope of implementation of the present invention is not limited thereto.

[0015] like figure 1 As shown in the figure, the ceramic xenon discharge lamp filled with lanthanide halide of this embodiment includes a sealed casing and a ceramic arc tube arranged in the sealed casing. The ceramic arc tube is provided with a filling space and electrodes. The filling space is filled with fillers, and the fillers are xenon gas, metal halide, and nano-silicon, wherein, by mass fraction, the metal halide is 60% to 70% of the filler, and the metal halide includes: sodium halide 80 %~90%, lanthanide halide 2%~6%, indium halide 0~1%, thallium halide 1%~1.5%, scandium halide 0.5%~1.5%, thorium halide 1%~5%, the electrode Thorium-coated tungsten or tungsten-thorium alloy.

[0016] The added lanthanide halide reduces the temperature of the bulb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com