Auto part quality detection method based on shape match

A quality inspection method and spare parts technology, applied in the field of image processing, can solve problems such as low detection efficiency, low detection quality, and many personnel, and achieve the effect of facilitating subsequent inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

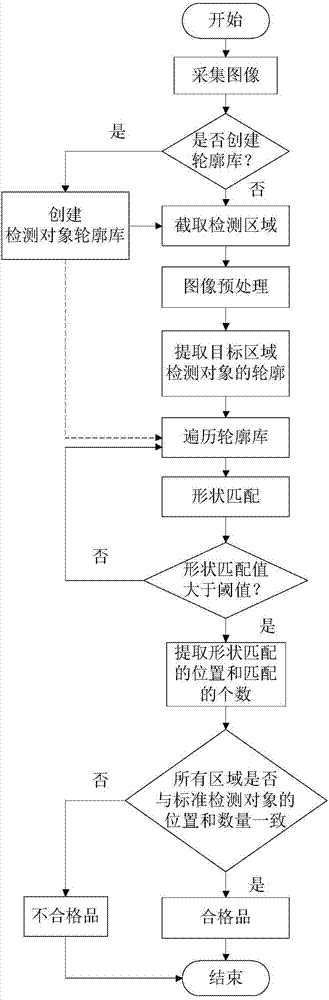

[0052] Such as figure 1 As shown, a kind of quality inspection method based on shape matching of auto parts of the present invention realizes steps as follows:

[0053] Step 1. Use industrial cameras to collect images of auto parts through network communication;

[0054] Step 2. Determine whether it is necessary to create a contour library, if necessary, proceed to step 3, otherwise go to step 4;

[0055]Step 3, intercepting the image of the detection object in the image of the auto parts, extracting the contour of the detection object based on the two-dimensional edge extraction method, and using the contour image of the detection object to create a shape matching template library for the auto parts;

[0056] The outline of the detection object is extracted based on the two-dimensional edge extraction method, and the specific process is as follows:

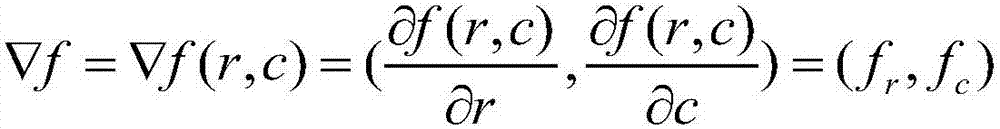

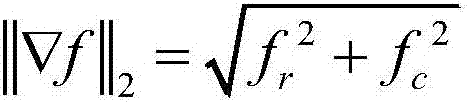

[0057] (31) The image function is represented by f(r,c), and the gradient vector of the image is calculated as:

[0058] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com