Large-power LED radiating structure

A technology with a heat dissipation structure and high power, which is applied in lighting and heating equipment, cooling/heating devices for lighting devices, lighting devices, etc., and can solve problems such as the inability to match the use of single crystal COBLEDs, and the inability to adapt and meet the heat dissipation requirements of high-power LEDs. , to achieve the effect of improving the ability and speeding up the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now with reference to the accompanying drawings, the embodiments of the present invention will be described in detail.

[0020] For the sake of illustration, the width, length and thickness of certain components in the schematic diagrams are sometimes exaggerated.

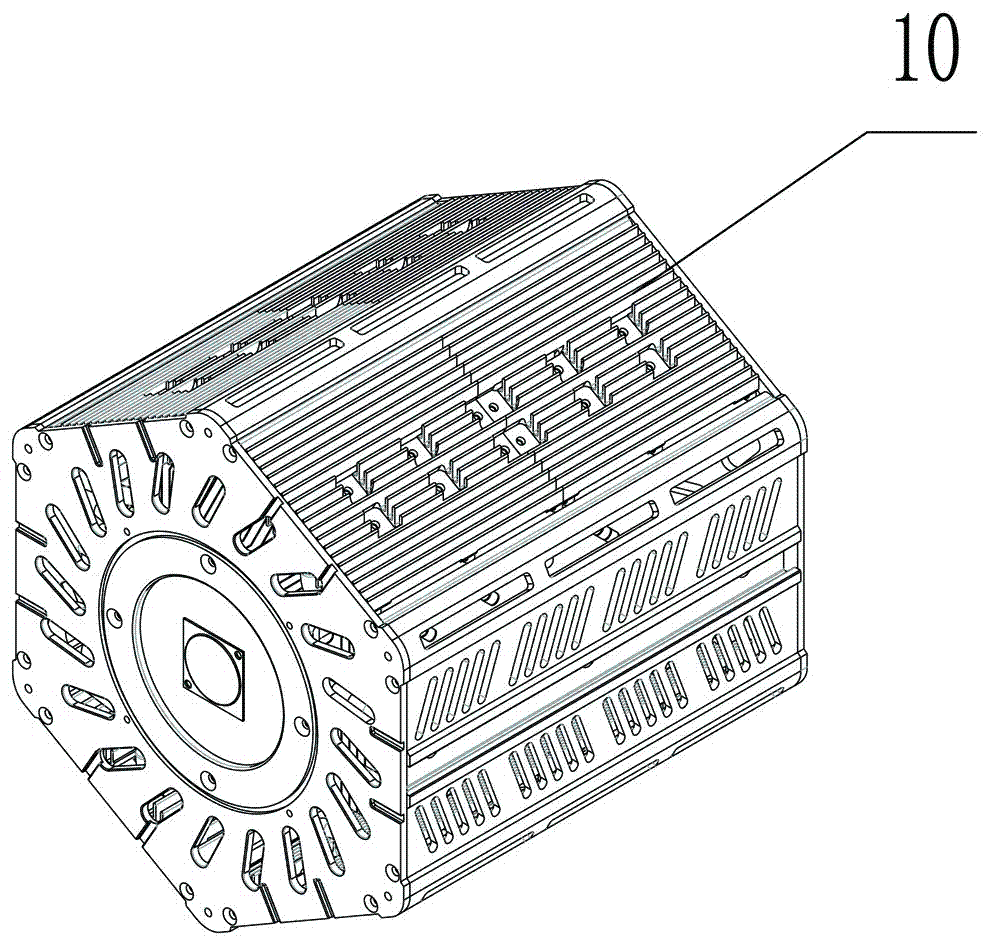

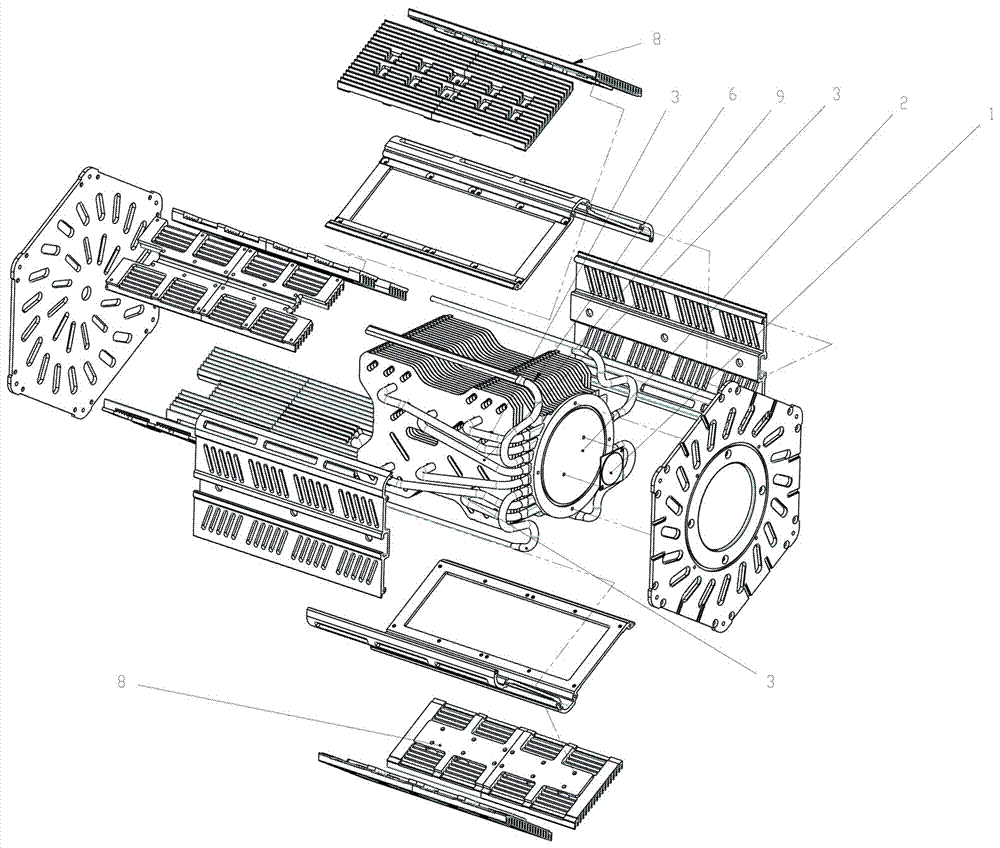

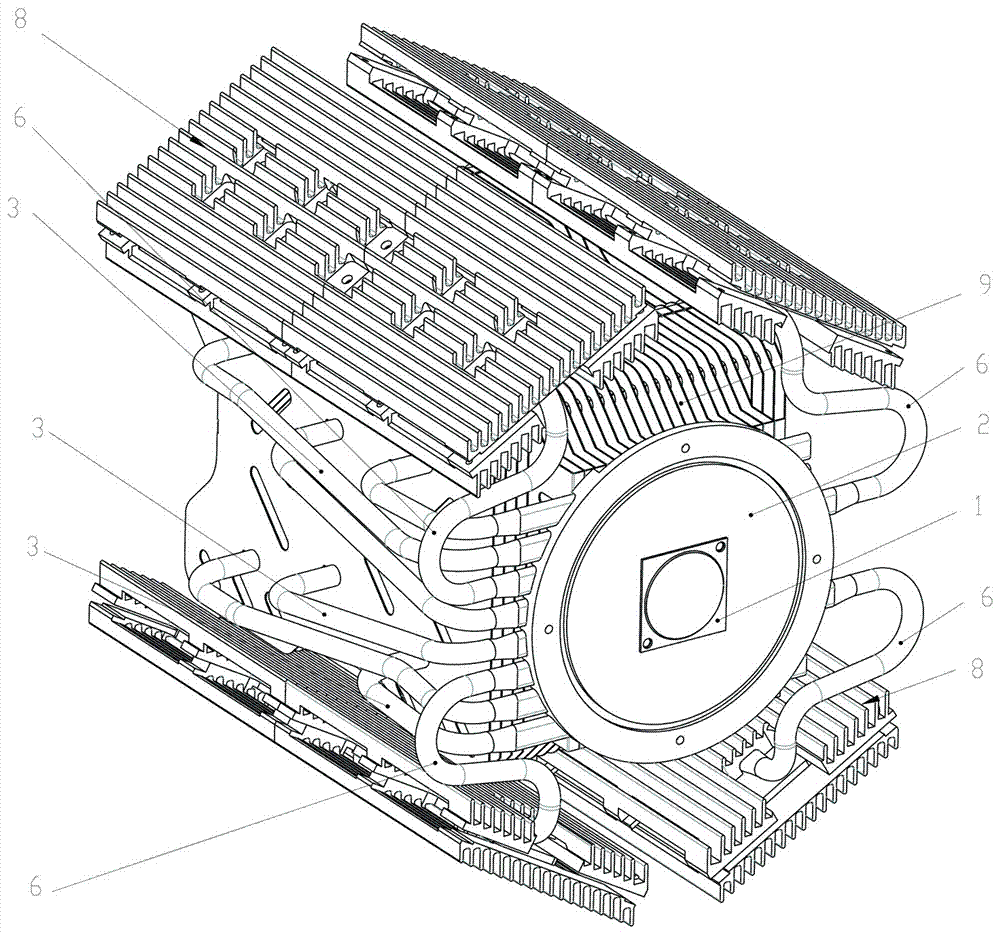

[0021] Such as Figure 1 to Figure 4 As shown, a high-power LED heat dissipation structure includes a housing 10, a heat dissipation bottom plate 2 bonded to an LED heat source 1, a heat pipe, and heat dissipation fins 9. The housing 10 includes a heat dissipation plate 8 with a heat dissipation groove 11, The heat dissipation fins 9 are disposed in the cavity enclosed by the housing 10 . The heat pipes are divided into two types. The first heat pipe 6 is connected to the heat dissipation base plate 2 such as welding, and extends axially in the heat dissipation plate 8. In this embodiment, the heat dissipation plate 8 has two layers. The first type of heat pipe 6 is arranged between two layers of heat diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com