Method for forming anticorrosive coating of compressor

An anti-corrosion coating and compressor technology, which is applied in the field of compressors, can solve the problems of poor density of metal material layers, poor adhesion, and inability to meet anti-corrosion requirements, and achieve improved anti-corrosion performance, low cost, and guaranteed protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

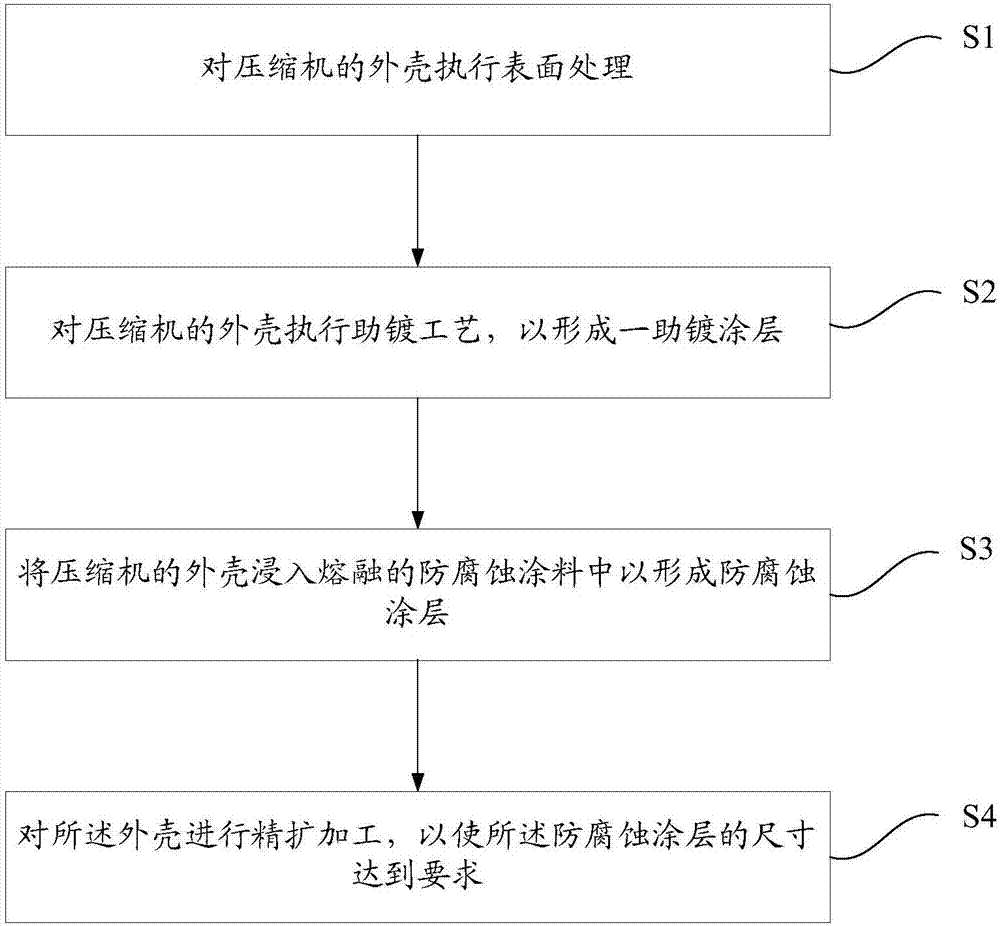

[0034] The core idea of the present invention is to provide a method for forming an anti-corrosion coating of a compressor, including: performing surface treatment on the shell of the compressor; performing a fluxing process on the shell of the compressor to form a fluxing coating; The outer shell of the machine is immersed in the molten anti-corrosion paint to form an anti-corrosion coating.

[0035] In the method for forming the anti-corrosion coating of the compressor provided by the present invention, the shell of the compressor is immersed in the molten anti-corrosion coating to form the anti-corrosion coating on the surface. That is, by adopting the method of hot dipping, an anti-corrosion coating with a certain thickness and good compactness can be formed on the shell of the compressor, so as to overcome the problem of the compressor being eroded during long-term use and prolong the service life of the compressor. life. Moreover, in the method provided by the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com