A kind of ultrasonic cleaning and purification method of polyphenylene sulfide

A purification method, polyphenylene sulfide technology, applied in the field of ultrasonic cleaning and purification of polyphenylene sulfide, can solve the problems of large product loss and cumbersome separation steps, and achieve simple operation, narrow molecular weight distribution, and good separation and purification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

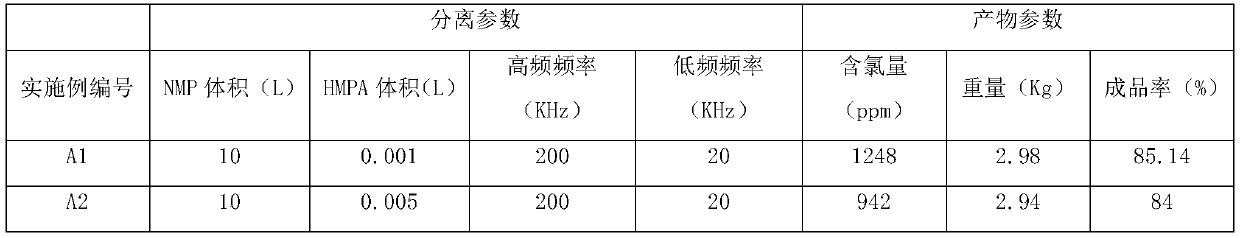

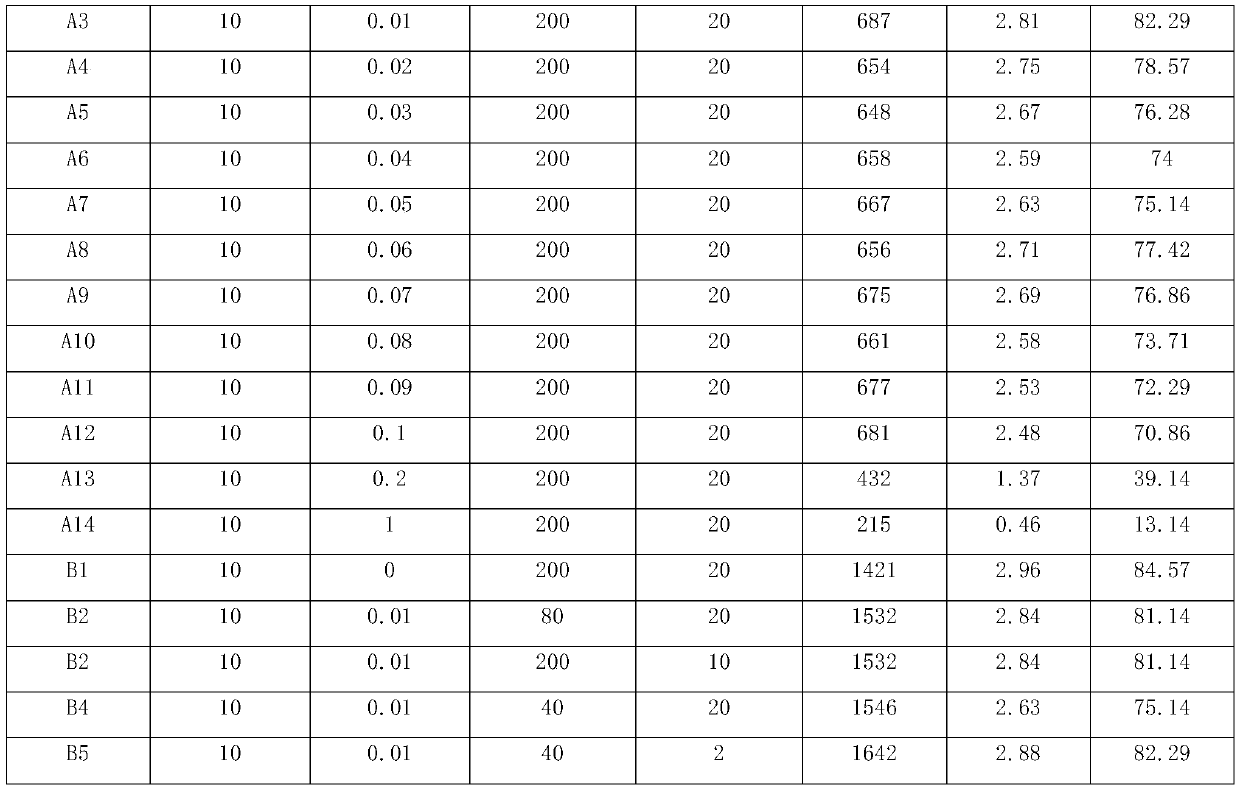

[0024] Example 1 Separation of crude polyphenylene sulfide to obtain separation product A1

[0025] (1) Ultrasonic high-frequency pre-cleaning: Add 3.5 kg of crude polyphenylene sulfide to an ultrasonic cleaning tank filled with 10 liters of N-methylpyrrolidone solvent and 0.001 liter of hexamethylphosphoric triamide solvent for cleaning. The ultrasonic temperature is 200KHz, and the ultrasonic temperature is 200°C. After cleaning for 120 minutes, the solid-liquid separation is carried out by rotary evaporation to obtain the pretreated solid;

[0026] (2) Ultrasonic low-frequency cleaning and purification: put the pretreated solid obtained in step (1) into an ultrasonic cleaning tank equipped with 10 liters of deionized water, the ultrasonic frequency is 20KHz, the ultrasonic temperature is 60°C, and it is cleaned for 240 minutes. , carrying out solid-liquid separation by vacuum filtration to obtain a purified solid;

[0027] (3) Vacuum-dry the purified solid obtained in step...

Embodiment 2

[0028] Example 2 Separation of crude polyphenylene sulfide to obtain separation product A2

[0029] (1) Ultrasonic high-frequency pre-cleaning: Add 3.5 kg of crude polyphenylene sulfide to an ultrasonic cleaning tank filled with 10 liters of N-methylpyrrolidone solvent and 0.005 liter of hexamethylphosphoric triamide solvent for cleaning. The ultrasonic temperature is 200KHz, and the ultrasonic temperature is 200°C. After cleaning for 120 minutes, the solid-liquid separation is carried out by rotary evaporation to obtain the pretreated solid;

[0030] (2) Ultrasonic low-frequency cleaning and purification: put the pretreated solid obtained in step (1) into an ultrasonic cleaning tank equipped with 10 liters of deionized water, the ultrasonic frequency is 20KHz, the ultrasonic temperature is 60°C, and it is cleaned for 240 minutes. , carrying out solid-liquid separation by vacuum filtration to obtain a purified solid;

[0031] (3) Vacuum-dry the purified solid obtained in step...

Embodiment 3

[0032] Example 3 Separation of crude polyphenylene sulfide to obtain isolated product A3

[0033] (1) Ultrasonic high-frequency pre-cleaning: Add 3.5 kg of crude polyphenylene sulfide into an ultrasonic cleaning tank filled with 10 liters of N-methylpyrrolidone solvent and 0.01 liter of hexamethylphosphoric triamide solvent for cleaning. The ultrasonic temperature is 200KHz, and the ultrasonic temperature is 200°C. After cleaning for 120 minutes, the solid-liquid separation is carried out by rotary evaporation to obtain the pretreated solid;

[0034] (2) Ultrasonic low-frequency cleaning and purification: put the pretreated solid obtained in step (1) into an ultrasonic cleaning tank equipped with 10 liters of deionized water, the ultrasonic frequency is 20KHz, the ultrasonic temperature is 60°C, and it is cleaned for 240 minutes. , carrying out solid-liquid separation by vacuum filtration to obtain a purified solid;

[0035] (3) Vacuum drying the purified solid obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com