Process for producing full polished glazed tiles

A production process and full glaze polishing technology, applied in the field of architectural ceramics processing, can solve the problems of low yield, high rejection rate, increased production cost, etc., and achieve the effect of compact brick structure, stable product performance, and improved overall strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

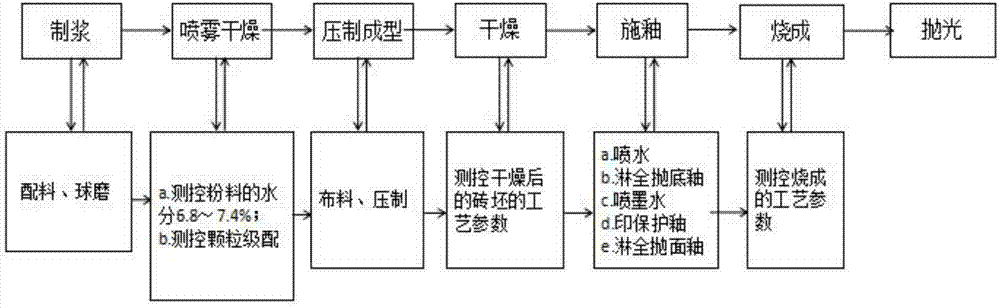

[0040] Embodiment 1-a kind of production technology of full cast glazed brick, comprises the steps:

[0041] (1) Pulping: select the mineral raw materials used to prepare full-glazed tiles for batching, and add them into a ball mill for ball milling to obtain slurry;

[0042] (2) Spray drying: The slurry is spray-dried to obtain powder, and the moisture content of the powder is measured and controlled at the discharge conveyor belt under the spray tower to be 6.8-7.4%, and the particle gradation is 0.5% for 20 mesh and 35% for 40 mesh , 62% for 80 mesh, 2.5% for below 100 mesh;

[0043] (3) Compression molding: the powder is transported to the press for distribution, and compression molding is performed to obtain bricks;

[0044] (4) Drying: dry the adobe, and measure and control the drying temperature of the adobe after drying to be 70°C, and the drying strength is 0.8MPa;

[0045] (5) Glazing:

[0046] a. The surface of the dried brick adobe is sprayed with water, and the...

Embodiment 2

[0053] Embodiment 2-a kind of production technology of full cast glazed brick, comprises the steps:

[0054] (1) Pulping: select the mineral raw materials used to prepare full-glazed tiles for batching, and add them into a ball mill for ball milling to obtain slurry;

[0055] (2) Spray drying: The slurry is spray-dried to obtain powder, and the moisture content of the powder is measured and controlled at the discharge conveyor belt under the spray tower to be 6.8-7.4%, and the particle gradation is 0.2% for 20 mesh and 47% for 40 mesh , 50% for 80 mesh, 2.8% for below 100 mesh;

[0056] (3) Compression molding: the powder is transported to the press for distribution, and compression molding is performed to obtain bricks;

[0057] (4) drying: dry the adobe, and measure and control the drying temperature of the adobe after drying to be 85°C, and the drying strength is 1.2MPa;

[0058] (5) Glazing:

[0059] a. The surface of the dried brick adobe is sprayed with water, and the...

Embodiment 3

[0066] Embodiment 3-a kind of production technology of full cast glazed brick, comprises the steps:

[0067] (1) Pulping: select the mineral raw materials used to prepare full-glazed tiles for batching, and add them into a ball mill for ball milling to obtain slurry;

[0068] Before the ball mill discharges, measure and control the process parameters of the slurry at the ball mill outlet, put the slurry into the transfer pool, ground pool or transfer tank, and perform sampling to detect the process parameters of the slurry; the slurry The process parameters of the material include moisture, fineness, flow rate and specific gravity;

[0069] The moisture content of the slurry discharged from the pulp outlet of the ball mill is controlled to be 32-35%, the fineness is controlled to be 250 mesh, the sieve residue is 1.1%, the flow rate is controlled to be 70s; the specific gravity is controlled to be 1.69g / ml;

[0070] The moisture content of the slurry in the transfer pool, gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com