Glass powder for preparing solar cell electrode, as well as paste composition, solar cell electrode and solar cell including same

A technology of solar cells and glass powder, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, circuits, photovoltaic power generation, etc., which can solve the problems of insufficient adhesion between solar cell electrodes and welding ribbons, high series resistance and conversion efficiency, Solve problems such as low adhesion of electrodes and ribbons, achieve the effect of providing conversion efficiency, excellent adhesive strength, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

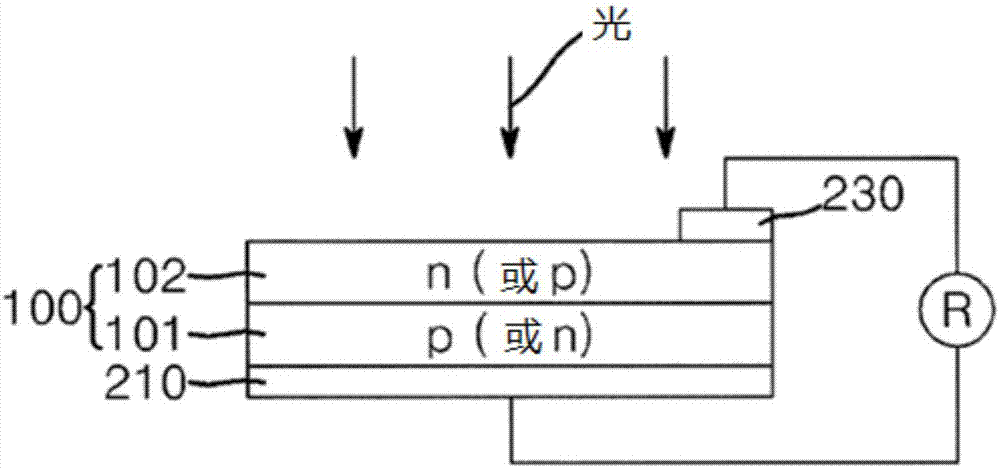

Image

Examples

Embodiment approach

[0034] According to a typical embodiment of the present invention, the solar cell electrode components include silver powder, sodium tellurite-trilead tetroxide-based glass powder and an organic vehicle. Now, the composition of the solar cell electrode of the present invention will be described in more detail.

[0035] (A) silver powder

[0036] According to a typical embodiment of the present invention, the paste composition for preparing solar cell electrodes contains silver powder as the conductive powder. The particle size of silver powder can be nano or micron. For example, silver powder may have a particle size of tens to hundreds of nanometers, or several to tens of microns. Alternatively, the silver powder may be a mixture of two or more silver powders having different particle sizes.

[0037] Silver powder can have a spherical, flake or amorphous shape.

[0038] The silver powder preferably has an average particle diameter (D50) of about 0.1 μm to about 10 μm, mor...

Embodiment 1~12 and comparative example 1~16

[0063] Examples 1-12 and Comparative Examples 1-16 adopted the composition of the glass frit shown in Table 1, prepared compositions for solar cell electrodes in the same manner, and evaluated the physical properties. It should be noted that the examples and comparative examples in Table 1 are intended to highlight the characteristics of one or more inventive examples, not to limit the scope of the present invention, nor to illustrate that the comparative examples are outside the scope of the present invention. Furthermore, the inventive subject matter is not limited to the specific details described in the examples and comparative examples.

[0064] Table 1

[0065]

[0066] As shown in Table 1, using the compositions prepared by using sodium tellurite pentahydrate and trilead tetroxide in Examples 1 to 12, and the components of the composition are within the preferred range of the present invention, the solar cells manufactured electrode, showing high adhesive strength and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com