A kind of anti-reduction low-temperature sintering high-frequency heat-stable dielectric ceramic and its preparation method

A low-temperature sintering technology for dielectric ceramics, applied in the field of dielectric ceramics, can solve problems such as poor repeatability, and achieve the effects of promoting the sintering process, low price, and reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

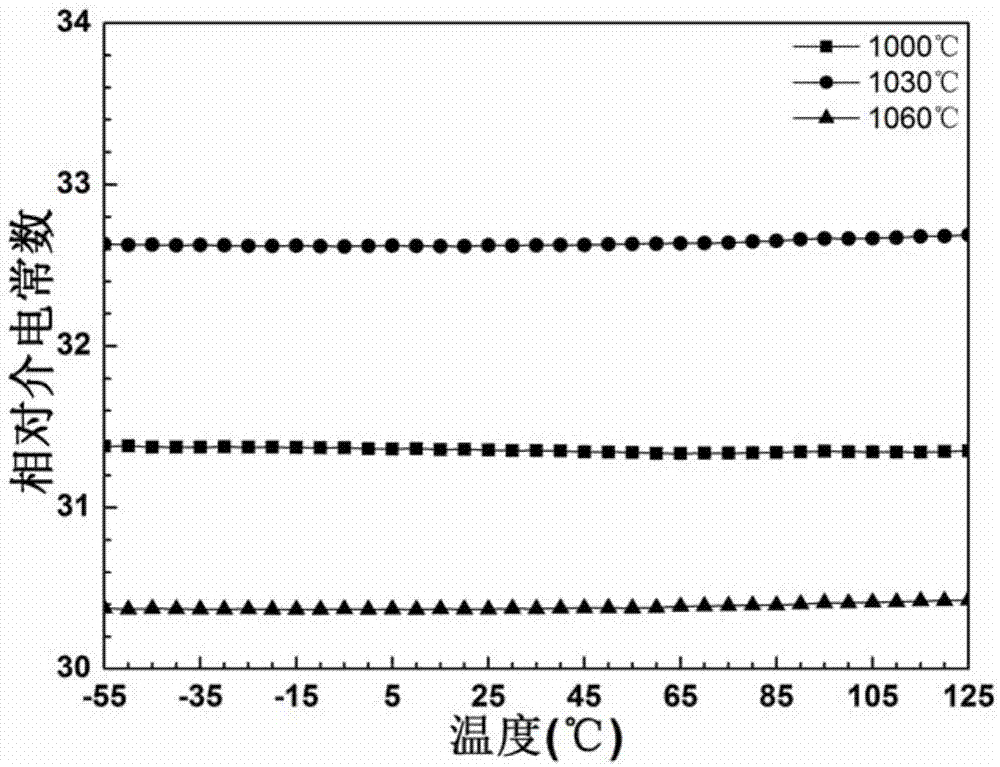

Image

Examples

Embodiment 1

[0028] The anti-reduction low-temperature sintering high-frequency heat-stable dielectric ceramic of this embodiment includes the following steps:

[0029] (1) Synthesis of the main crystal phase: SrCO 3 , CaCO 3 , ZrO 2 、TiO 2 As a raw material, press (Sr 0.55 Ca 0.45 )(Zr 0.96 Ti 0.04 )O 3The stoichiometric ratio ingredients were mixed, planetary ball milled for 90min (with deionized water as solvent, and the speed was 300 rpm), dried and ball milled through an 80-mesh sieve, placed in a corundum crucible and pre-sintered at 1150°C in air for 4h. Planetary ball mill 90min (with deionized water as solvent, rotating speed is 300 rev / min), ball mill after drying and pass through 80 mesh sieves, obtain (Sr 0.55 Ca 0.45 )(Zr 0.96 Ti 0.04 )O 3 .

[0030] (2) Preparation of BaO-B by melt quenching method 2 o 3 -SiO 2 (30:60:10) Glass powder: with BaCO 3 、H 3 BO 3 , SiO 2 The raw materials are prepared according to the molar ratio and mixed evenly, placed in a qu...

Embodiment 2

[0040] The anti-reduction low-temperature sintering high-frequency heat-stable dielectric ceramic of this embodiment includes the following steps:

[0041] (1) Synthesis of the main crystal phase: SrCO 3 , CaCO 3 , ZrO 2 、TiO 2 As a raw material, press (Sr 0.55 Ca 0.45 )(Zr 0.96 Ti 0.04 )O 3 The stoichiometric ratio ingredients were mixed, planetary ball milled for 90min (using deionized water as solvent, the speed was 300 rpm), dried and ball milled through an 80 mesh sieve, placed in a corundum crucible and pre-sintered at 1100°C in air for 4.5h. Through planetary ball milling for 90min (with deionized water as solvent, the rotating speed is 300 rpm), after drying, ball milling is passed through 80 mesh sieves to obtain (Sr 0.55 Ca 0.45 )(Zr 0.96 Ti 0.04 )O 3 .

[0042] (2) Preparation of BaO-B by melt quenching method 2 o 3 -SiO 2 (30:60:10) Glass powder: with BaCO 3 、H 3 BO 3 , SiO 2 The raw materials are prepared according to the molar ratio and mixed ...

Embodiment 3

[0047] The anti-reduction low-temperature sintering high-frequency heat-stable dielectric ceramic of this embodiment includes the following steps:

[0048] (1) Synthesis of the main crystal phase: SrCO 3 , CaCO 3 , ZrO 2 、TiO 2 As a raw material, press (Sr 0.55 Ca 0.45 )(Zr 0.96 Ti 0.04 )O 3 The stoichiometric ratio ingredients were mixed, planetary ball milled for 90 minutes (using deionized water as solvent, the speed was 300 rpm), dried and ball milled through an 80-mesh sieve, placed in a corundum crucible and pre-sintered at 1200°C in air for 3.5 hours, Through planetary ball milling for 90min (with deionized water as solvent, the rotating speed is 300 rpm), after drying, ball milling is passed through 80 mesh sieves to obtain (Sr 0.55 Ca 0.45 )(Zr 0.96 Ti 0.04 )O 3 .

[0049] (2) Preparation of BaO-B by melt quenching method 2 o 3 -SiO 2 (30:60:10) Glass powder: with BaCO 3 、H 3 BO 3 , SiO 2 The raw materials are prepared according to the molar ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com