Method for preparing potassium superoxide powder through metallic potassium spray-oxidizing process

A technology of potassium superoxide and oxidation method, applied in the direction of alkali metal oxides, etc., can solve the problems of low purity and high risk of potassium superoxide powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

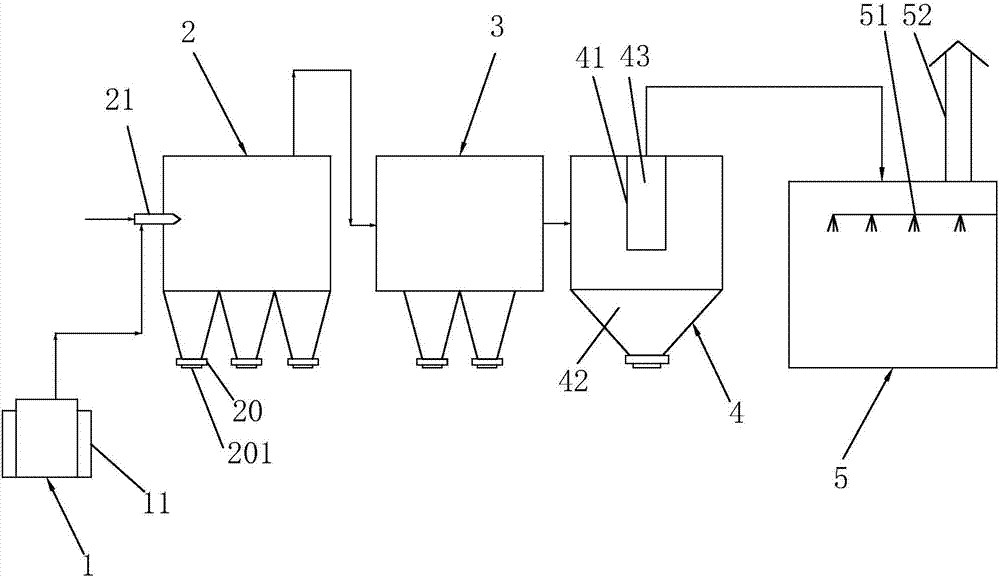

[0027] Embodiment one: a kind of equipment that metal potassium oxidation method prepares potassium superoxide powder, combines figure 1 and figure 2 , including a molten potassium tank 1, a reactor 2 connected to the molten potassium tank 1, and a collector 3, a dust removal tank 4 and a dust reduction chamber 5 connected to the reactor 2 in sequence.

[0028] A heating wire (not shown) is wound around the outside of the molten potassium tank 1, and the outer side of the heating wire is wrapped with an insulating cover 11, so as to avoid heat loss too fast. The solid potassium is put into the molten potassium tank 1, and when the electric heating wire is heated to a temperature of 80° C., the solid potassium is melted to form liquid potassium after being heated by the electric heating wire.

[0029] A spray gun 21 is fixed at the feed port of the reactor 2, and the spray gun 21 includes an outer chamber 211 and an inner chamber 212 coaxially arranged, and one end of the out...

Embodiment 2

[0034] Embodiment two: a kind of method that metal potassium spray oxidation method prepares potassium superoxide powder, adopt the equipment of embodiment one, process according to the following steps:

[0035] Select solid potassium with a purity of 98.5%, put solid potassium into molten potassium tank 1, and heat to 80° C. to melt to form liquid potassium.

[0036] The water content of the compressed air is less than 0.5%, the pressure of the compressed air is adjusted to 0.3MPa, and the flow velocity of the compressed air is adjusted to 6 m / s, and the flow velocity of the liquid potassium is 0.3 m / s. Adjust the temperature of the spray gun 21 to 260°C, and at this time, the negative pressure formed at the muzzle of the spray gun 21 is -0.025MPa.

[0037] In this process, liquid potassium is rapidly oxidized by air to form potassium superoxide powder, and the particle size of potassium superoxide powder is between 8-12 mesh.

Embodiment 3

[0038] Embodiment 3: A method for preparing potassium superoxide powder by metal potassium spray oxidation method. Compared with Embodiment 1, the equipment used is different in that the diameter of the inner chamber 212 close to the muzzle 213 is 1.3 mm. Specific steps are as follows:

[0039] Select solid potassium with a purity of 98.8%, put solid potassium into molten potassium tank 1, and heat to 90° C. to melt to form liquid potassium.

[0040] The moisture content of compressed air is less than 0.5%. The pressure of the compressed air is adjusted to 0.5 MPa, and the flow velocity of the compressed air is adjusted to be 8 m / s, and the flow velocity of the liquid potassium is 0.5 m / s. Adjust the temperature of the spray gun 21 to 280° C. At this time, the negative pressure formed at the muzzle 213 of the spray gun 21 is -0.035 MPa.

[0041] In this process, liquid potassium is rapidly oxidized by air to form potassium superoxide powder, and the particle size of potassiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com