Method and equipment for preparing graphene oxide

A graphene and fossil technology, applied in the field of graphene oxide preparation, can solve the problems of inaccurate control of reaction temperature, long reaction time, slow heat and mass transfer, etc., so as to improve reaction efficiency, production safety, and reaction yield. rate and selectivity, the effect of improving selectivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

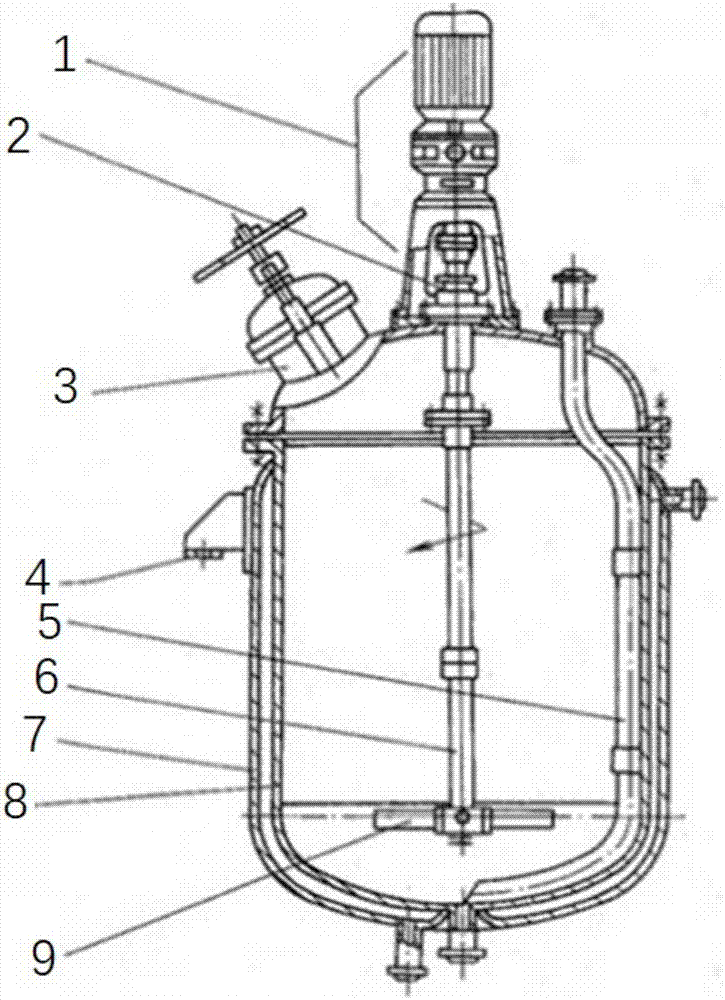

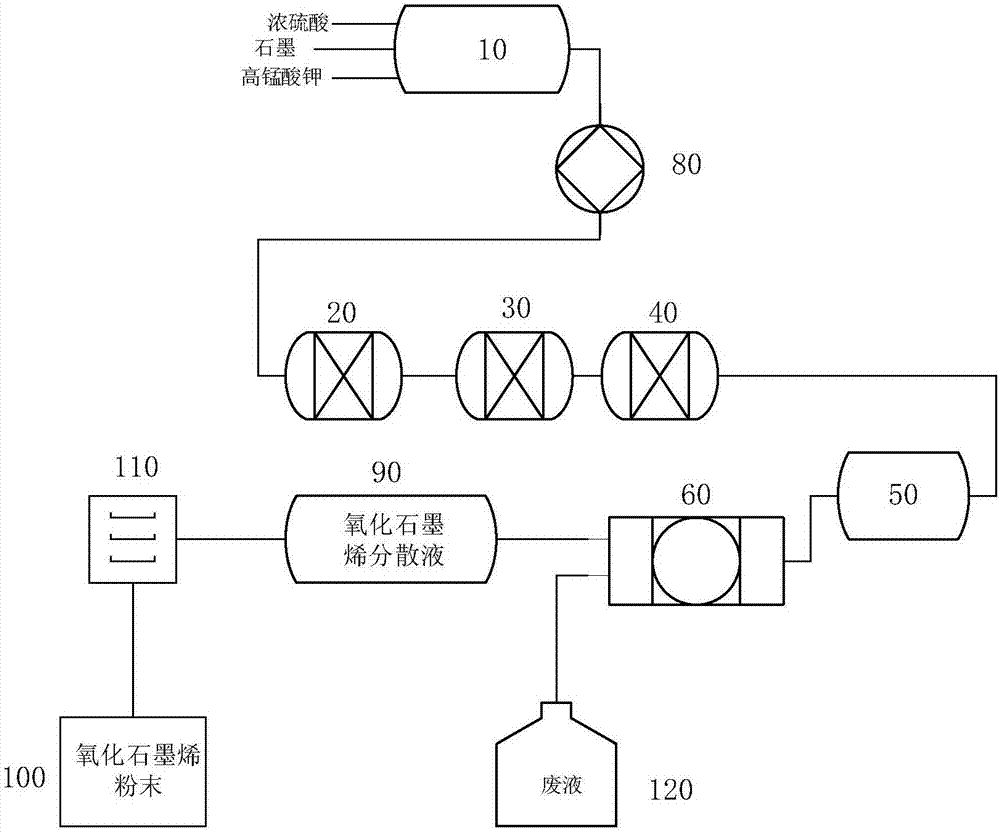

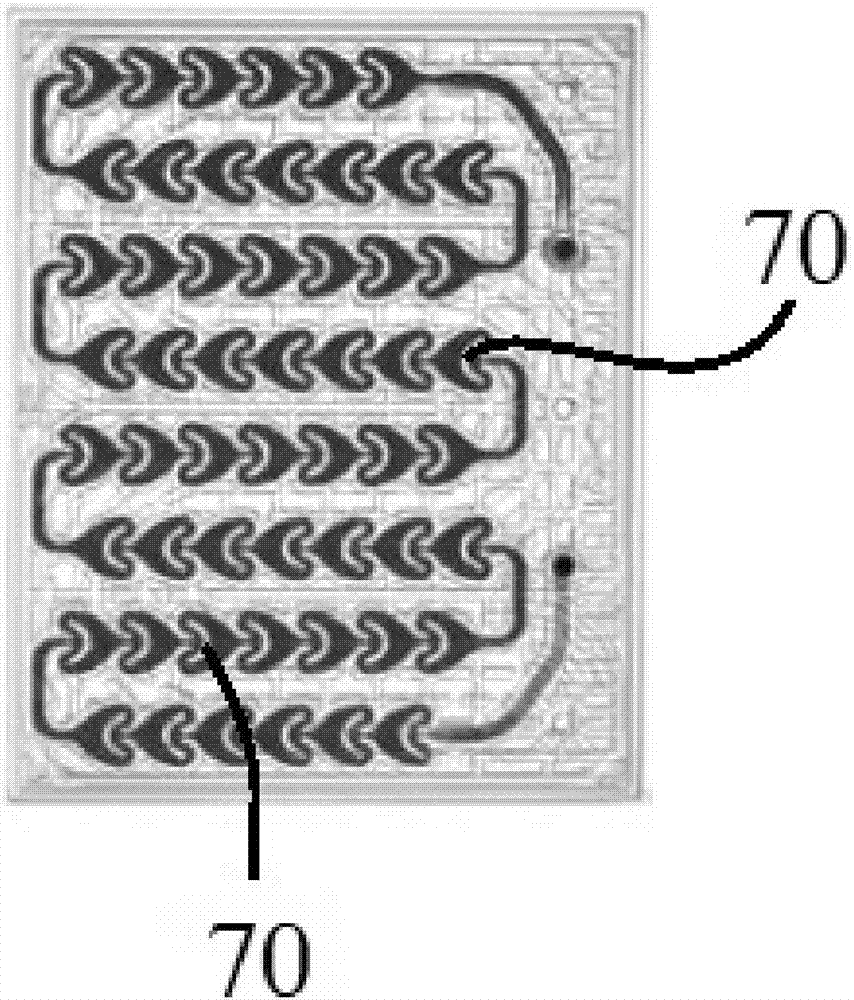

[0050] (1) equipment for preparing graphene oxide, such as figure 2 As shown, including: premixer 10, microchannel reactor 20-40, collection tank 50, and cross-flow filtration device 60, said premixer 10, microchannel reactor 20-40, collection tank 50 and cross-flow The filtering devices 60 are connected in sequence, and a metering pump 80 is arranged between the premixer 10 and the microchannel reactor 20 . Concentrated sulfuric acid, graphite and potassium permanganate are mixed at low temperature in the premixer 10, pumped into the microchannel reactor 20-40 through the metering pump 80, and flow into the collection tank 50 after the microchannel reactor 20-40 reacts, cross-flow Filtration device 60 carries out cross-flow filtration to the product mixture collected in 50, obtains graphene oxide dispersion liquid after cross-flow filtration device 60 filters and collects in the collection tank 90 that is connected with the product outlet of cross-flow filtration device 60, ...

Embodiment 2

[0058] (1) The equipment for preparing graphene oxide is the same as in Example 1.

[0059] (2) the method for preparing graphene oxide, comprising:

[0060] Premixed at 0°C, the ratio of the premixed liquid is prepared in the premixer 1 according to the ratio of graphite: potassium permanganate: concentrated sulfuric acid = 1:3:30;

[0061] The premixed solution is fed into the microchannel reactor 2-4 through the metering pump 8 for reaction, the reaction temperature is 45°C, and the reaction residence time of a single heart-shaped microreaction channel is 20s; and

[0062] After the reaction is completed, the product enters the collection tank 5, and after being washed by the cross-flow filter device 6, the graphene oxide dispersion product can be obtained.

[0063] The product yield is 172%. The oxygen to carbon molar ratio of the product is 0.58.

[0064] The graphene oxide dispersion is further dried to obtain a graphene oxide powder product.

Embodiment 3

[0066] (1) The equipment for preparing graphene oxide is the same as in Example 1.

[0067] (2) the method for preparing graphene oxide, comprising:

[0068] Premix at 15°C, the ratio of the premix is prepared in the premixer 1 according to the ratio of graphite: potassium permanganate: concentrated sulfuric acid = 1:3:30;

[0069] The premixed solution is fed into the microchannel reactor 2-4 through the metering pump 8 for reaction, the reaction temperature is 55°C, and the reaction residence time of a single heart-shaped microreaction channel is 20s; and

[0070] After the reaction is completed, the product enters the collection tank 5, and after being washed by the cross-flow filter device 6, the graphene oxide dispersion product can be obtained.

[0071] The product yield is 180%. The oxygen to carbon molar ratio of the product is 0.65.

[0072] The graphene oxide dispersion is further dried to obtain a graphene oxide powder product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com