Treatment method and system of byproduct hydrochloric acid in chlorination process of toluene or chloro-toluene

A by-product hydrochloric acid, production process technology, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chemical instruments and methods, etc., can solve problems that affect the economic benefits of chlorine products, fail to meet industrial requirements, pollute the environment, and achieve realization Effects of circular economy development, resource conservation and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

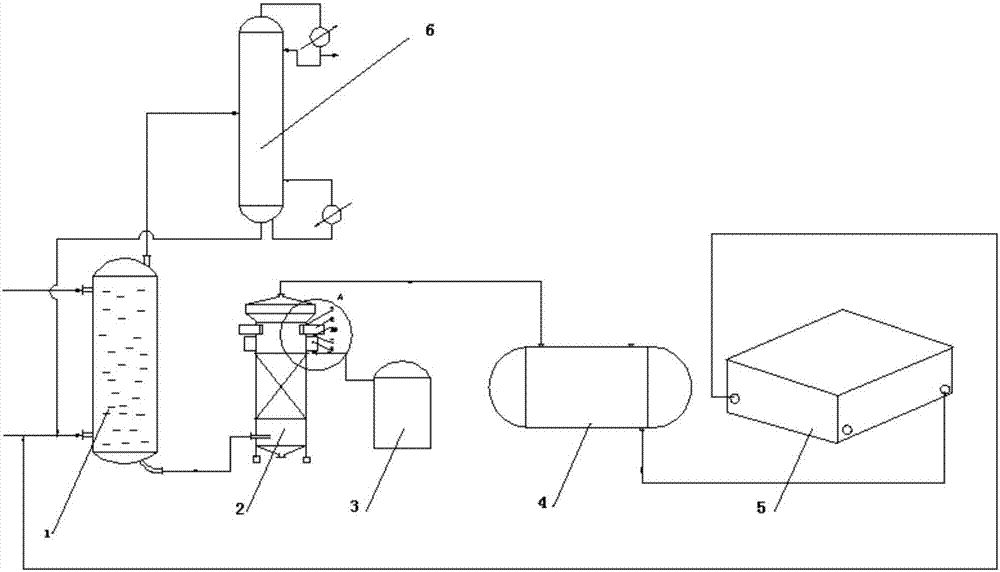

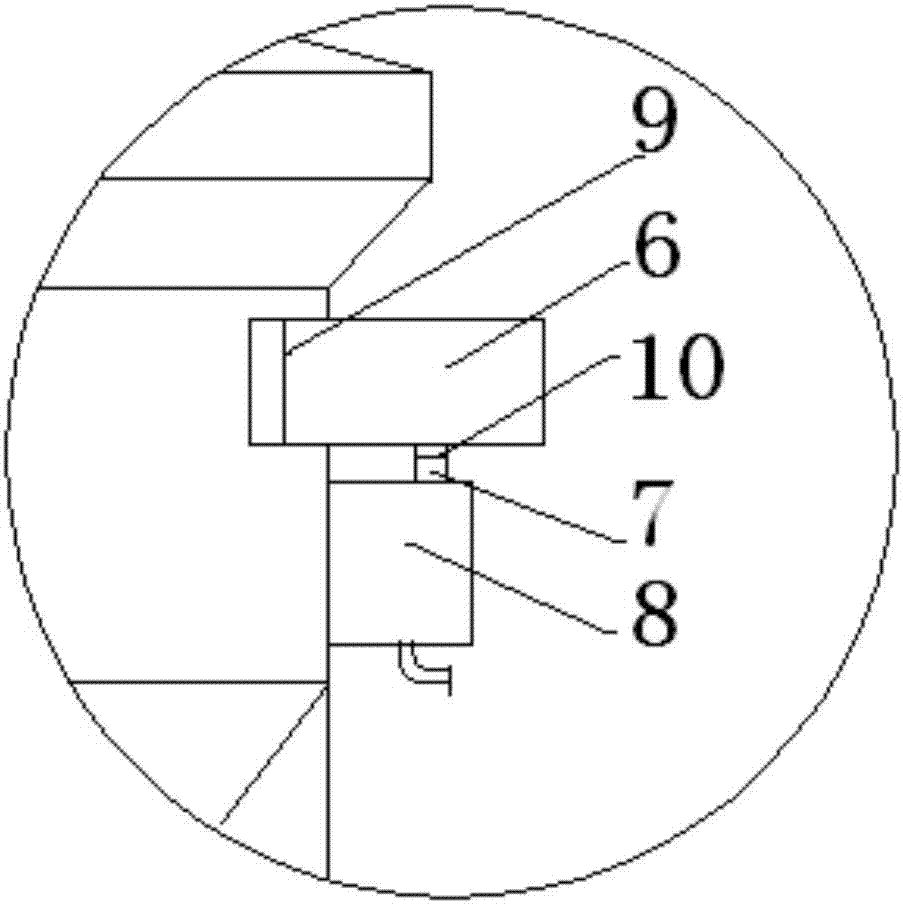

[0028] see figure 1 , a treatment system for by-product hydrochloric acid in the chlorination production process of toluene or chlorotoluene, comprising an extraction tower 1, a carbon fiber adsorption tower 2, a storage tank 3, a steam generating device, a condenser 4 and an extraction tank 5, the extraction tower The heavy liquid outlet of 1 is connected with the liquid inlet at the bottom of the carbon fiber adsorption tower 2, and the liquid outlet at the top of the carbon fiber adsorption tower 2 is connected with the storage tank 3; the steam generating device ( figure 1 Not shown in ) is connected with the desorption gas inlet of carbon fiber adsorption tower 2 through steam inlet pipe, the desorption gas outlet of carbon fiber adsorption tower 2 bottom is connected with the intake inlet of condenser 4, and the condensate outlet of condenser 4 is connected with The inlet of the extraction tank 5 is connected, and the outlet of the oil phase of the extraction tank 5 is m...

Embodiment 2

[0033] A kind of processing method of by-product hydrochloric acid in the production process of toluene chlorination, comprises the steps:

[0034] 1) The by-product hydrochloric acid from the toluene chlorination system (including toluene 31-33W / W%, chlorotoluene 31-33W / W% and hydrochloric acid 31-33W / W%) enters from the light liquid inlet at the top of the extraction tower 1, The extraction agent benzene enters from the heavy liquid inlet at the bottom of the extraction tower 1, and the weight ratio of the by-product hydrochloric acid to the extraction agent is 8:5. They are contacted countercurrently in the extraction tower. The temperature in the extraction tower is controlled to be 40°C and the pressure is 0.15Mpa. Benzene absorbs toluene and chlorotoluene in the by-product hydrochloric acid, extracts from the light liquid inlet at the top of the extraction tower, and extracts the raffinate from the heavy liquid outlet of the tower still;

[0035] 2) The raffinate phase e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com