Flattening equipment for cardboard bonding

A paper shell and equipment technology, which is applied in the field of flattening equipment for paper shell bonding, can solve the problems of easy adhesion of debris, time-consuming and laborious, and poor flattening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

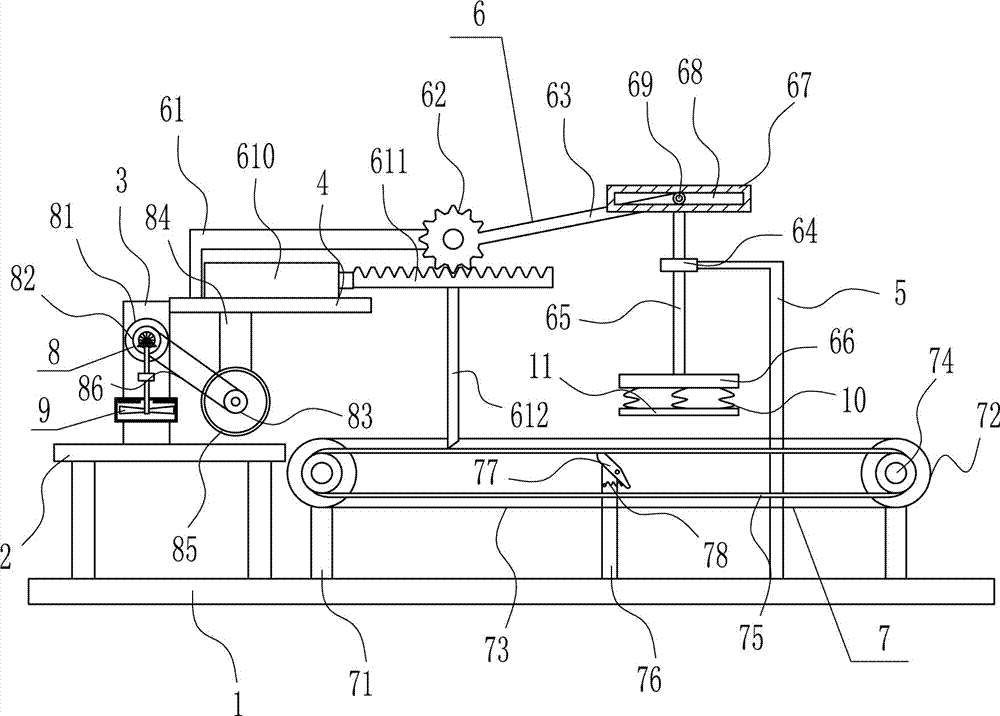

[0037] A flattening device for paper shell bonding, such as Figure 1-7 As shown, it includes a bottom plate 1, a placement table 2, a mounting plate 3, a horizontal plate 4, a 7-shaped rod 5, a flattening device 6 and a conveying device 7. The top left side of the bottom plate 1 is equipped with a placement table 2. A mounting plate 3 is installed on the side, a horizontal plate 4 is installed on the upper right side of the mounting plate 3, a conveying device 7 is arranged on the top right side of the bottom plate 1, a 7-type rod 5 is installed on the right side of the top of the bottom plate 1, and the 7-type rod 5 is located on the conveying device 7. On the rear side, a flattening device 6 is provided between the tail end of the 7-shaped rod 5 and the top of the horizontal plate 4. The flattening device 6 is located above the conveying device 7. The moving parts of the flattening device 6 contact the driving parts of the conveying device 7.

Embodiment 2

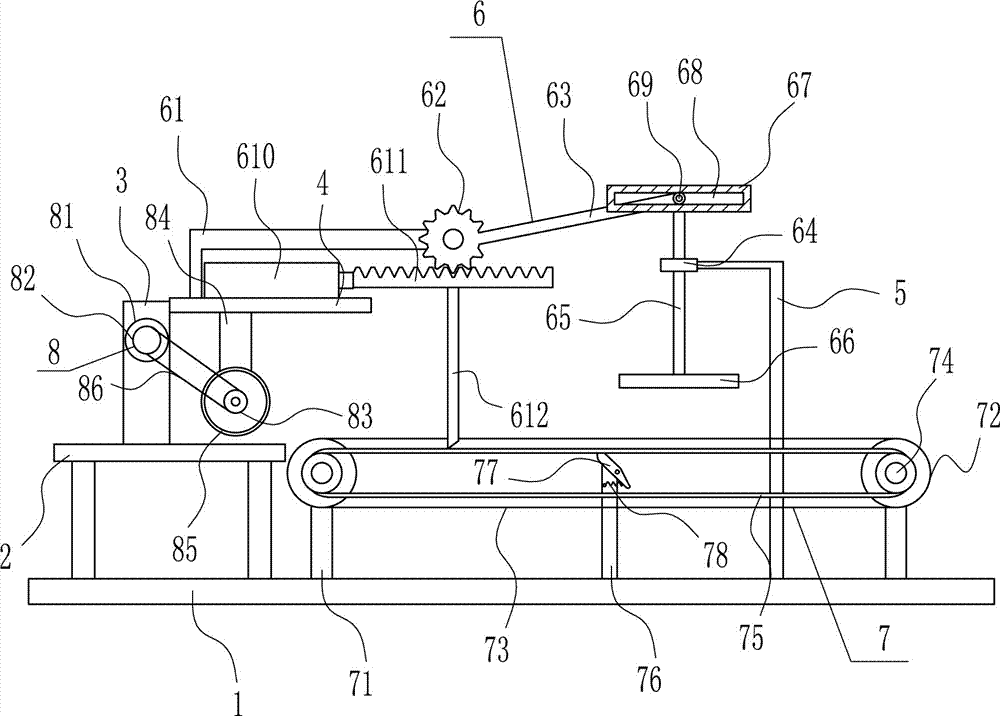

[0039] A flattening device for paper shell bonding, such as Figure 1-7 As shown, it includes a bottom plate 1, a placement table 2, a mounting plate 3, a horizontal plate 4, a 7-shaped rod 5, a flattening device 6 and a conveying device 7. The top left side of the bottom plate 1 is equipped with a placement table 2. A mounting plate 3 is installed on the side, a horizontal plate 4 is installed on the upper right side of the mounting plate 3, a conveying device 7 is arranged on the top right side of the bottom plate 1, a 7-type rod 5 is installed on the right side of the top of the bottom plate 1, and the 7-type rod 5 is located on the conveying device 7. On the rear side, a flattening device 6 is provided between the tail end of the 7-shaped rod 5 and the top of the horizontal plate 4. The flattening device 6 is located above the conveying device 7. The moving parts of the flattening device 6 contact the driving parts of the conveying device 7.

[0040] The flattening device ...

Embodiment 3

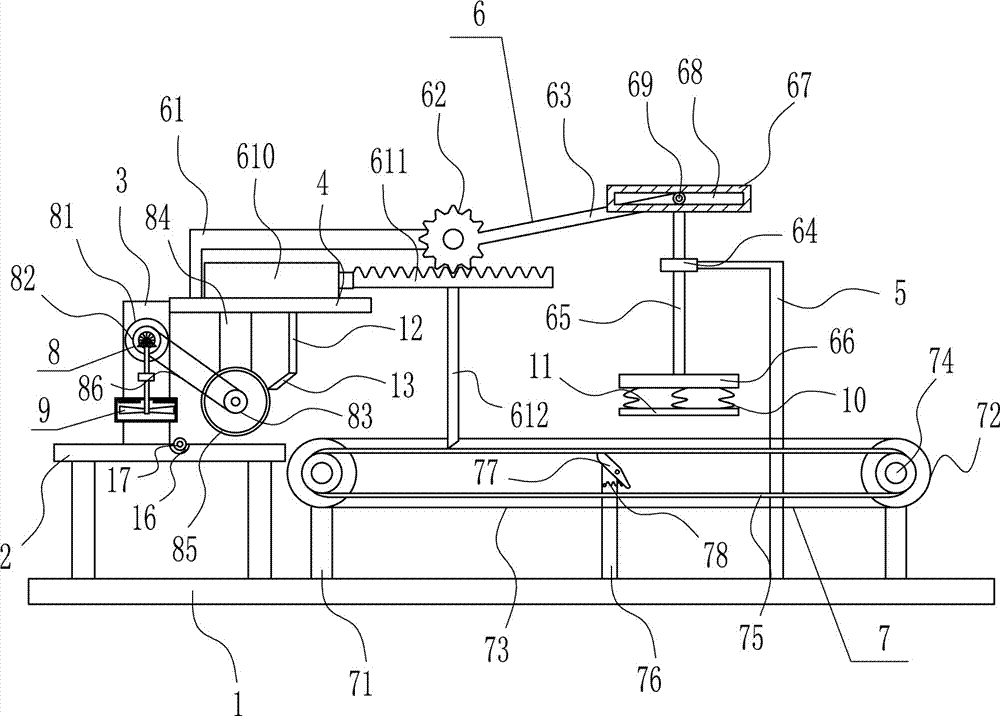

[0042] A flattening device for paper shell bonding, such as Figure 1-7 As shown, it includes a bottom plate 1, a placement table 2, a mounting plate 3, a horizontal plate 4, a 7-shaped rod 5, a flattening device 6 and a conveying device 7. The top left side of the bottom plate 1 is equipped with a placement table 2. A mounting plate 3 is installed on the side, a horizontal plate 4 is installed on the upper right side of the mounting plate 3, a conveying device 7 is arranged on the top right side of the bottom plate 1, a 7-type rod 5 is installed on the right side of the top of the bottom plate 1, and the 7-type rod 5 is located on the conveying device 7. On the rear side, a flattening device 6 is provided between the tail end of the 7-shaped rod 5 and the top of the horizontal plate 4. The flattening device 6 is located above the conveying device 7. The moving parts of the flattening device 6 contact the driving parts of the conveying device 7.

[0043] The flattening device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com