Composite cleaning method and device

A cleaning device and technology to be cleaned, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as low cleaning efficiency and incomplete cleaning, achieve high cleaning efficiency, and improve peeling. Speed, wide cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

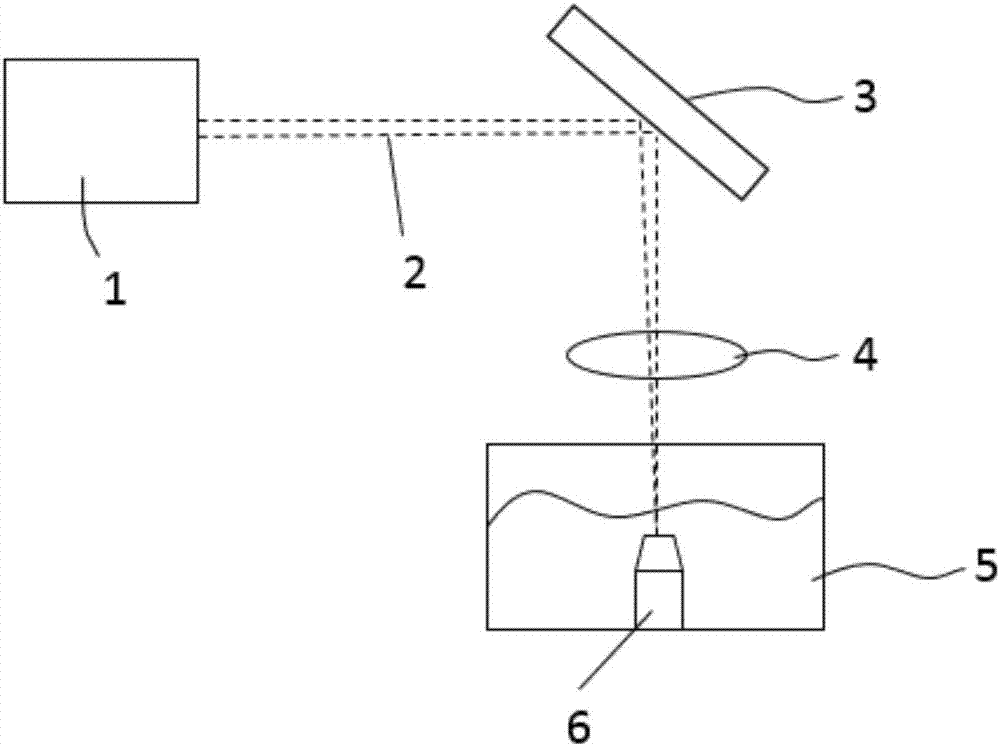

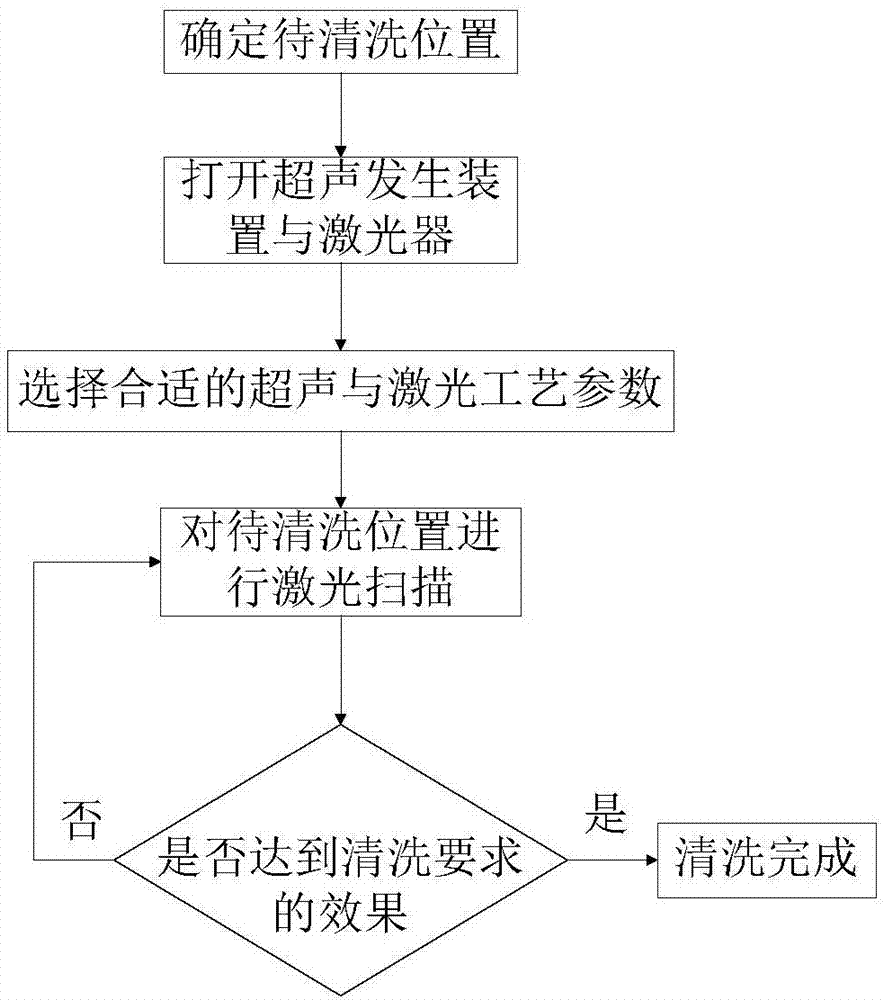

[0037] The composite cleaning method provided in this embodiment includes the following steps:

[0038] (1) Position the parts to be cleaned and determine the positions to be cleaned;

[0039] (2) Turn on the ultrasonic generator 5, select appropriate parameters according to the material characteristics of the substrate and the dirt, the frequency is 30-50Hz, the amplitude is 400-500μm, and the ultrasonic horn maintains an angle of 30-45oC with the laser beam axis.

[0040] (3) Turn on the laser 1, and select the laser process parameters according to the material characteristics of the substrate and the dirt. The process parameters of the laser beam are laser wavelength 1064nm, output power 200-500W, scanning speed 5-500mm / s, laser spot size 80 -100μm, scanning pitch is 30-100μm.

[0041] (4) Start cleaning. The movement of the mirror 3 is controlled by the automatic control operating system to control the cleaning path. The laser beam 2 passes through the focusing mirror 4 and then ...

Embodiment 2

[0048] This embodiment is used to clean the rust on the metal surface and specifically includes the following steps:

[0049] 1) Position the parts to be cleaned and determine the positions to be cleaned;

[0050] (2) Turn on the ultrasonic generator 5 and select appropriate parameters according to the material characteristics of the metal. The ultrasonic frequency is set to 120-250Hz, the amplitude is 200-300μm, and the ultrasonic horn maintains an angle of 60oC with the laser beam axis.

[0051] (3) Turn on the laser 1, select the laser process parameters according to the material characteristics of the metal, the laser output power is set to 1000-2000W, the scanning speed is 6000-7000mm / s, the laser spot size is 500-600μm, and the scanning distance is 300-500μm.

[0052] (4) Start cleaning. The movement of the mirror 3 is controlled by the automatic control operating system to control the cleaning path. The laser beam 2 passes through the focusing mirror 4 and then focuses on the w...

Embodiment 3

[0056] This embodiment is used to clean dirt on the surface of rubber products, specifically including the following steps:

[0057] 1) Position the parts to be cleaned and determine the positions to be cleaned;

[0058] (2) Turn on the ultrasonic generator 5 and select appropriate parameters according to the material characteristics of the rubber product. The ultrasonic frequency is set to 800-1000Hz, the amplitude is 300-500μm, and the ultrasonic horn maintains an angle of 80oC with the laser beam axis.

[0059] (3) Turn on the laser 1, and select the laser process parameters according to the material characteristics of the rubber product. The laser output power is set to 1000-2000W, the scanning speed is 6000-7000mm / s, the laser spot size is 500-600μm, and the scanning distance is 300-500μm. .

[0060] (4) Start cleaning. The movement of the mirror 3 is controlled by the automatic control operating system to control the cleaning path. The laser beam 2 passes through the focusing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com