Ceramic catalytic filter element for flue gas purification and flue gas desulfurization and denitrification integrated dust removal method

A flue gas purification, desulfurization and denitrification technology, which is applied in the field of flue gas purification, can solve the problems of loss of denitrification catalyst supported by substrate ceramic materials, short service life and replacement cycle, and reduced denitrification efficiency, so as to increase catalytic active sites and prolong The effect of service life and improvement of denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

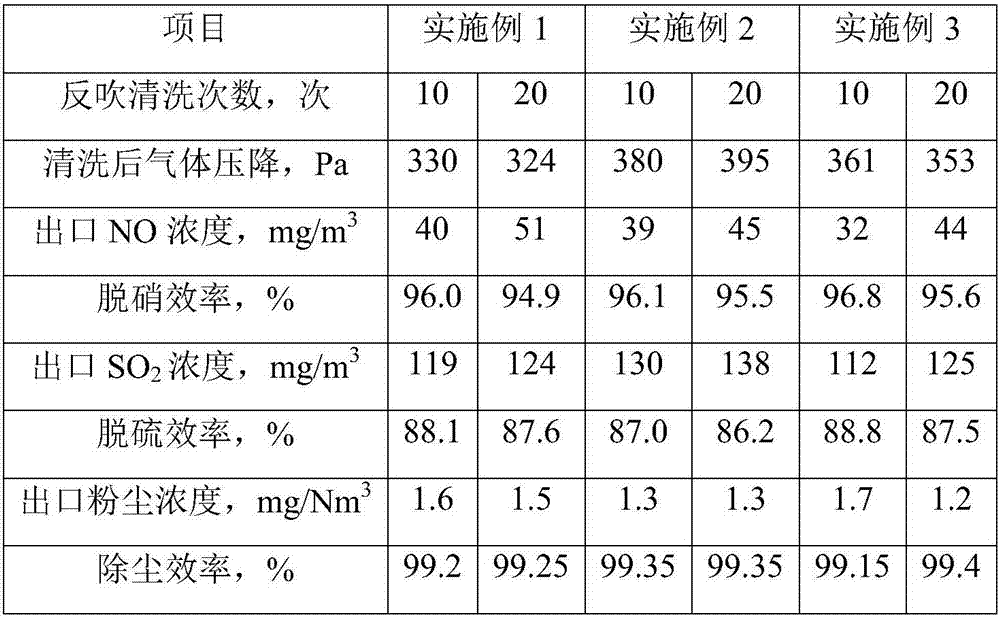

Examples

Embodiment 1

[0040] The ceramic catalytic filter element for flue gas purification in this embodiment is prepared by a method comprising the following steps:

[0041] 1) Take a microporous alumina ceramic filter tube with a pore size of 40-60 μm, and use a mixture of ethanol and water with a volume ratio of 1:1 to perform ultrasonic cleaning, dry it at 80°C after cleaning, and use it as a substrate for later use;

[0042] 2) According to the molar ratio of ethylene glycol methyl ether and ethanolamine, the mixed solvent is prepared in a ratio of 1:0.2;

[0043] Take zinc acetate dihydrate, add it to the mixed solvent, and stir at 60°C for 2 hours to prepare a mixed sol with a zinc acetate concentration of 0.3mol / L;

[0044] 3) Immerse the matrix in step 1) into the mixed sol obtained in step 2), and immerse under negative pressure for 0.5 h until the pores of the matrix are saturated with adsorption; after taking out the matrix, scrape off the remaining impregnating liquid on the inner and...

Embodiment 2

[0054] The ceramic catalytic filter element for flue gas purification in this embodiment is prepared by a method comprising the following steps:

[0055] 1) Take a microporous alumina ceramic filter tube with a pore size of 50-70 μm, and use a mixture of ethanol and water with a volume ratio of 1:1 to perform ultrasonic cleaning, dry it at 80°C after cleaning, and use it as a substrate for later use;

[0056] 2) According to the molar ratio of ethylene glycol methyl ether and ethanolamine, a mixed solvent is prepared in a ratio of 1:0.3;

[0057] Take zinc acetate dihydrate, add it to the mixed solvent, and stir at 65°C for 1.5h to prepare a mixed sol with a zinc acetate concentration of 0.4mol / L;

[0058] 3) Immerse the matrix in step 1) into the mixed sol obtained in step 2), and immerse under negative pressure for 1 hour until the pores of the matrix are absorbed and saturated; after taking out the matrix, scrape off the remaining impregnating liquid on the inner and outer ...

Embodiment 3

[0068] The ceramic catalytic filter element for flue gas purification in this embodiment is prepared by a method comprising the following steps:

[0069] 1) Take a microporous alumina ceramic filter tube with a pore size of 40-60 μm, and use a mixture of ethanol and water with a volume ratio of 1:1 to perform ultrasonic cleaning, dry it at 80°C after cleaning, and use it as a substrate for later use;

[0070] 2) According to the molar ratio of ethylene glycol methyl ether and ethanolamine, the mixed solvent is prepared in a ratio of 1:0.4;

[0071] Take zinc acetate dihydrate, add it to the mixed solvent, and stir at 70°C for 1 hour to prepare a mixed sol with a concentration of zinc acetate of 0.5mol / L;

[0072] 3) Immerse the matrix in step 1) into the mixed sol obtained in step 2), and immerse under negative pressure for 1 hour until the pores of the matrix are absorbed and saturated; after taking out the matrix, scrape off the remaining impregnating liquid on the inner and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com