Calcium silicate lithium-system novel biological activity ceramic support and preparation method and purpose thereof

A technology of bioactive ceramics and calcium-lithium silicate, which is applied in prosthesis, tissue regeneration, medical science, etc., can solve the problem of insufficient cartilage regeneration ability, and achieve good dual bioactivity, good repair, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Preparation of Li by sol-gel method 2 Ca 4 Si 4 o 13 bioactive ceramic scaffold

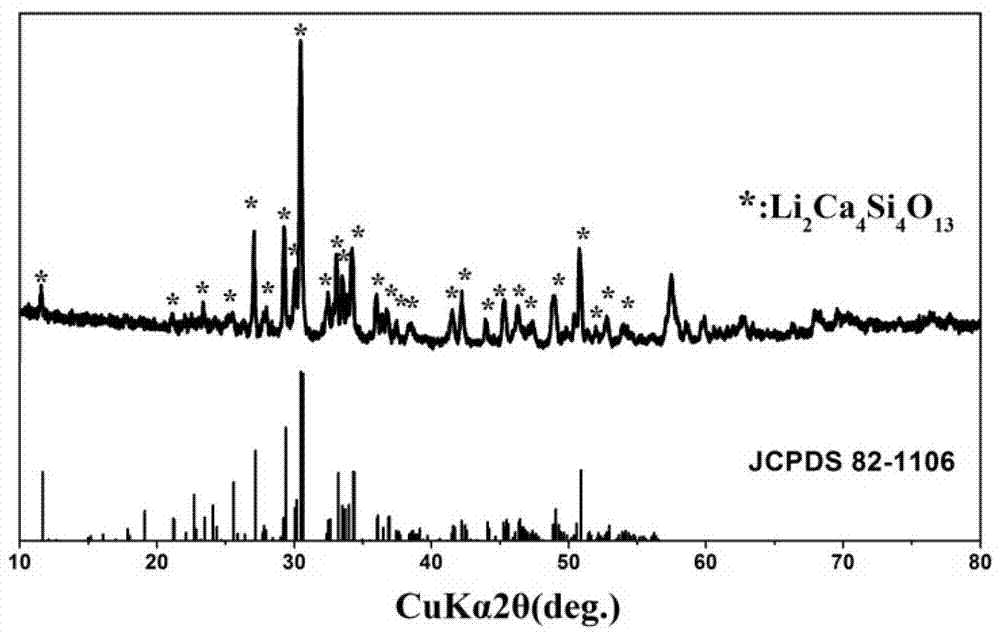

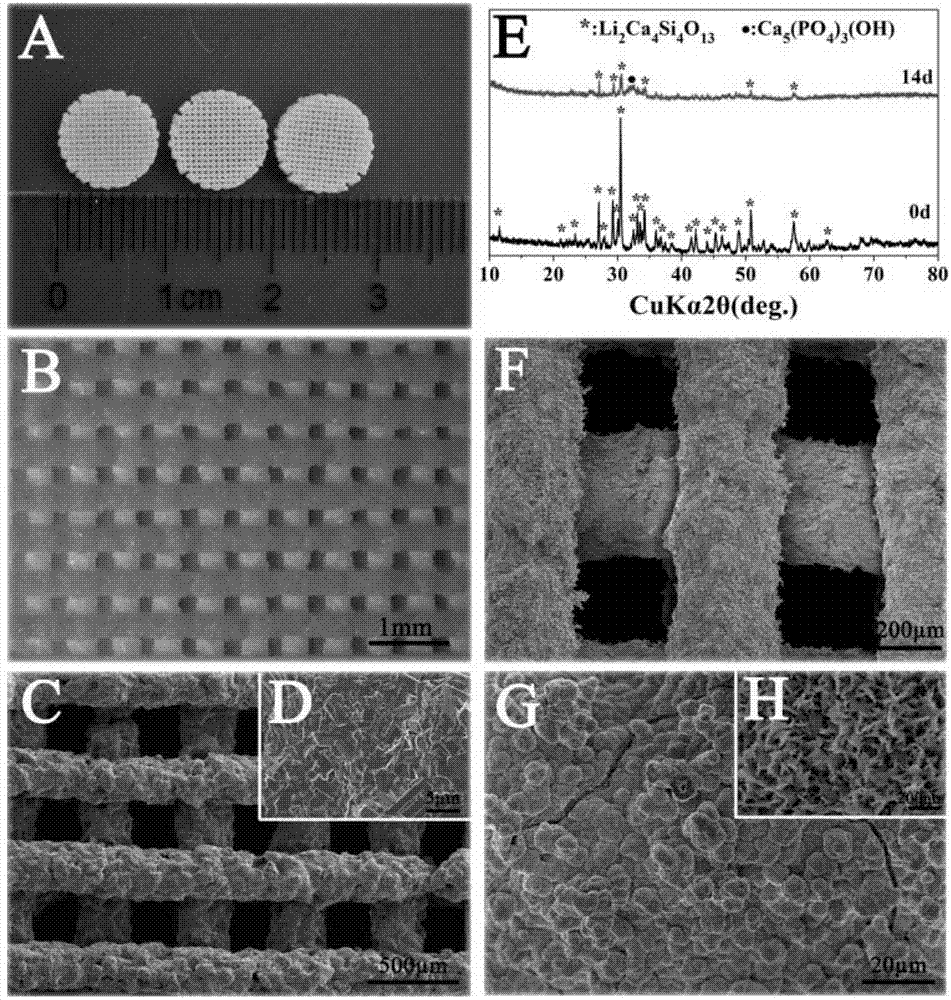

[0093] (1) Tetraethyl orthosilicate, deionized water and 2mol L -1 The nitric acid was mixed and stirred at a molar ratio of 1:8:0.08 for 0.5h to completely hydrolyze. According to the stoichiometric ratio Li:Ca:Si=2:4:4, lithium nitrate and calcium nitrate were added in sequence, and stirred for 5 hours to obtain a clear solution. Then the obtained clear solution was sealed in an oven at 60°C for 24 hours and dried at 120°C for 72 hours to obtain a xerogel; the xerogel was ball-milled for 6 hours and sieved, calcined at 940°C for 3 hours, and cooled naturally to obtain Li 2 Ca 4 Si 4 o 13 For bioactive ceramic powder, its XRD pattern can be found in figure 1 , it can be seen that it is a pure phase;

[0094] (2) Li will be obtained 2 Ca 4 Si 4 o 13 Bioactive ceramic powder: sodium alginate: F127 was mixed at a mass ratio of 1:0.06:0.8, and the printing program was designed ...

Embodiment 2

[0097] Preparation of Li by sol-gel method 2 Ca 2 Si 2 o 7 bioactive ceramic scaffold

[0098] (1) Tetraethyl orthosilicate, deionized water and 3mol L -1 The nitric acid was mixed and stirred at a molar ratio of 1:9:0.06 for 1 hour to completely hydrolyze. According to the stoichiometric ratio Li:Ca:Si=2:2:2, lithium nitrate and calcium nitrate were added in sequence, and stirred for 5 hours to obtain a clear solution. Then the obtained clear solution was sealed in an oven at 50°C for 36 hours and dried at 120°C for 60 hours to obtain a xerogel; the xerogel was ball-milled for 5 hours and sieved, calcined at 850°C for 2 hours, and cooled naturally to obtain Li 2 Ca 2 Si 2 o 7 For bioactive ceramic powder, its XRD pattern can be found in Figure 9 , it can be seen that it is a pure phase;

[0099] (2) Li will be obtained 2 Ca 2 Si 2 o 7Bioactive ceramic powder: sodium alginate: F127 was mixed at a mass ratio of 1:0.08:1.0, and the printing program was designed u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com