Shake-up device

A technology for installing plates and containers, which is applied in the field of medical devices, can solve the problems of narrow application range, slow shaking speed, and poor shaking effect, and achieve the effect of wide application range, fast shaking speed, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

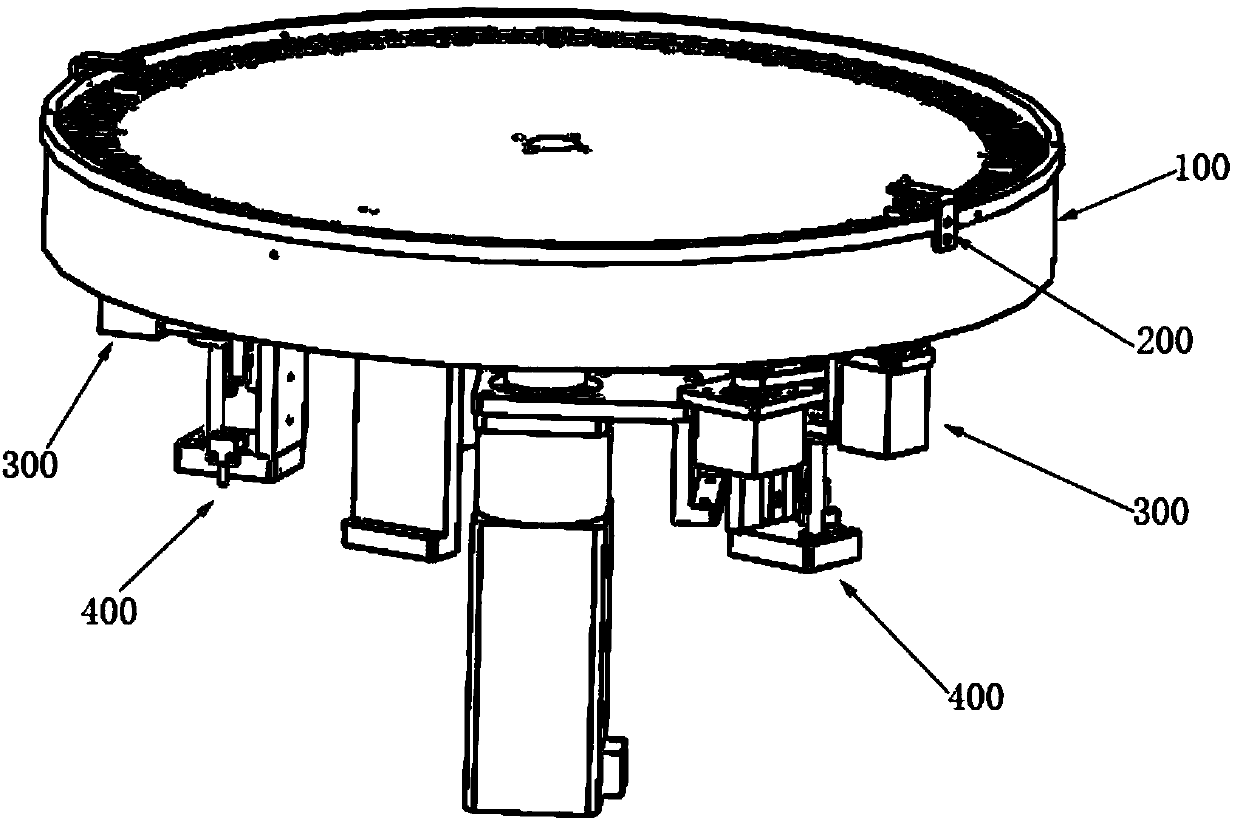

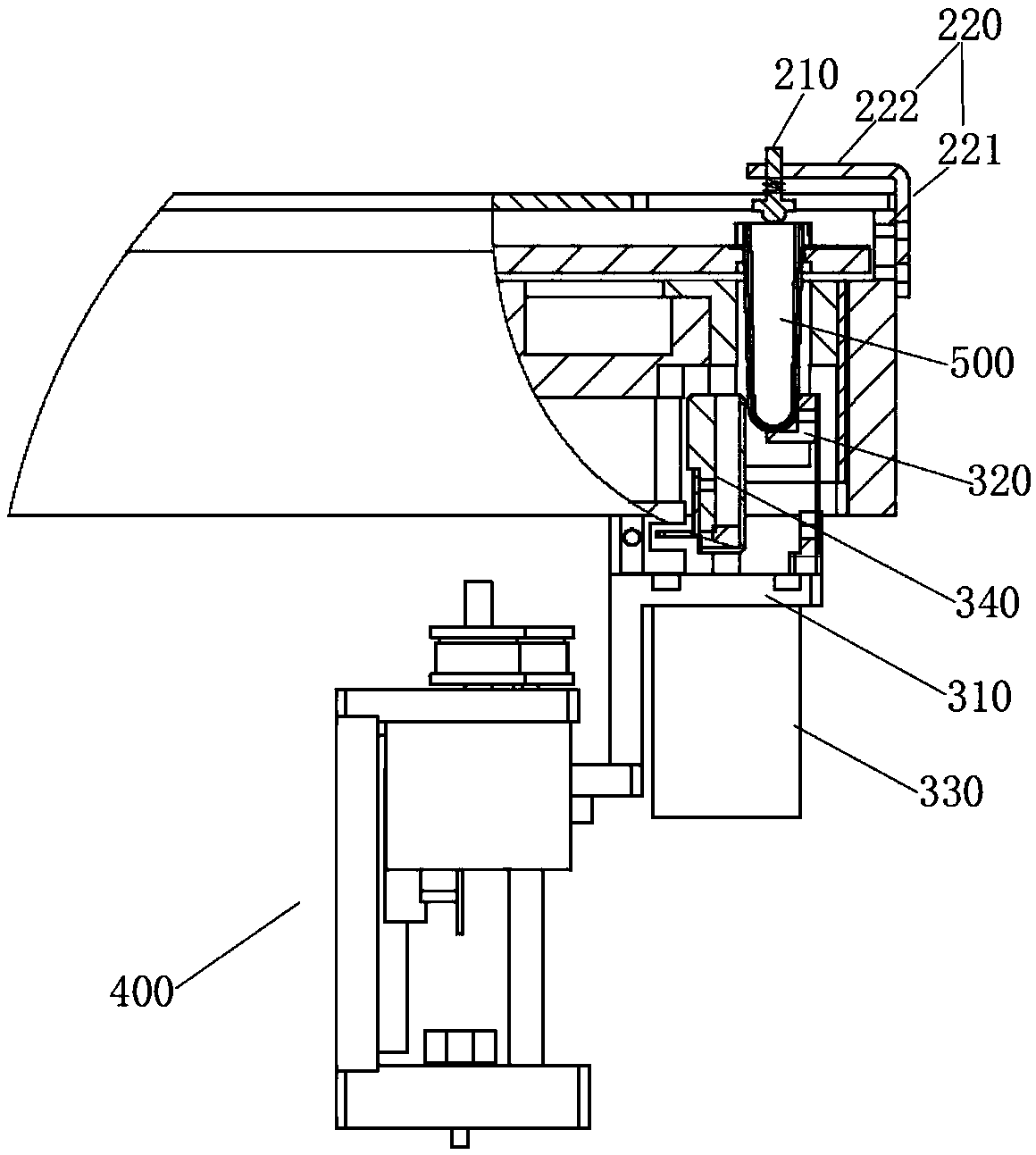

[0039] This embodiment provides a shaking device, such as figure 1 and 2 As shown, it includes a lifting mechanism 400, a shaking mechanism 300 and a container positioning mechanism 200. The lifting mechanism 400 controls the lifting of the shaking mechanism 300, and the reactant container (reaction cup 500 in this embodiment) placed on the reaction disk 100 Hold it up to the container positioning mechanism 200, and then shake the reactants in the cuvette 500 evenly. Wherein, the container positioning mechanism 200 is arranged above the cuvette 500, and includes a positioning column 210 and a positioning column fixing plate 220. The positioning column fixing plate 220 includes a vertical rod 221 and a cross arm 222. The vertical rod 221 is fixed on the reaction disk 100. The positioning column 210 is located below the cross arm 222 , above the cuvette 500 at the reaction position, and opposite to the upper port of the cuvette 500 . When the cuvette 500 is supported by the sh...

Embodiment 2

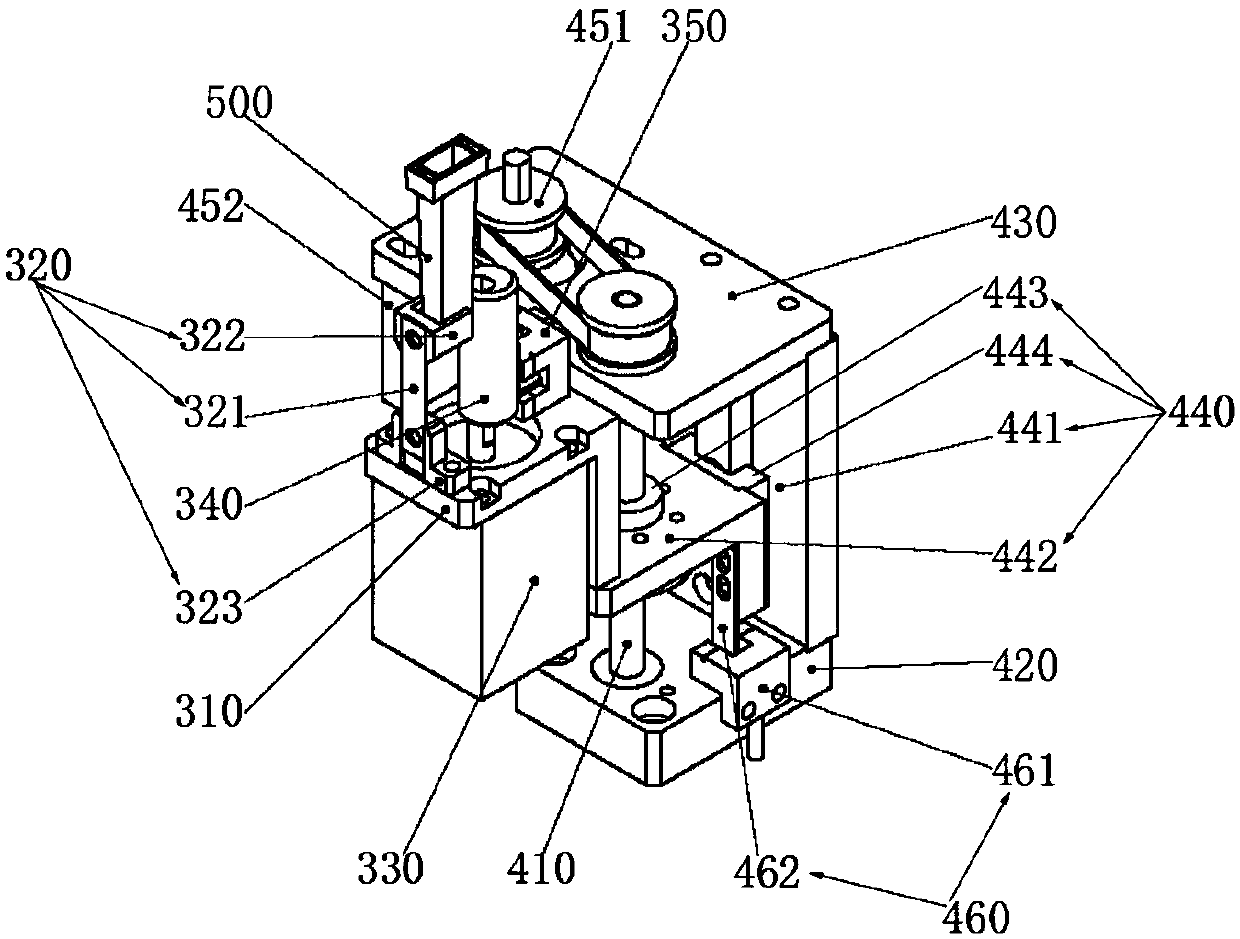

[0048] Such as image 3 As shown, this embodiment provides a preferred lifting mechanism 400 on the basis of Embodiment 1, including a lifting screw 410 , a screw bottom plate 420 , a screw upper plate 430 , a lifting rail assembly 440 and a synchronous pulley set 451 . Wherein, the bottom plate 420 of the screw rod is arranged at the lower end of the lifting screw rod 410 , and the upper plate 430 of the screw rod is arranged at the upper end of the lifting screw rod 410 . The lifting guide rail assembly 440 includes a slider group and a guide rail plate 441 standing between the screw upper plate 430 and the screw bottom plate 420. The slider group is installed on the lifting screw 410 through a screw nut 443. The shaking mechanism 300 The mounting plate 310 is fixedly connected with the slider group. The synchronous pulley group 451 is arranged on the upper plate 430 of the screw mandrel or the bottom plate 420 of the screw mandrel, the rotating shaft of its driving wheel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com