Automatic spraying production line and process

An automatic spraying and production line technology, applied in spray booths, spraying devices, etc., can solve problems such as poor spraying effect at splicing joints, and achieve efficient and stable spraying, good drying effect, and comprehensive spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

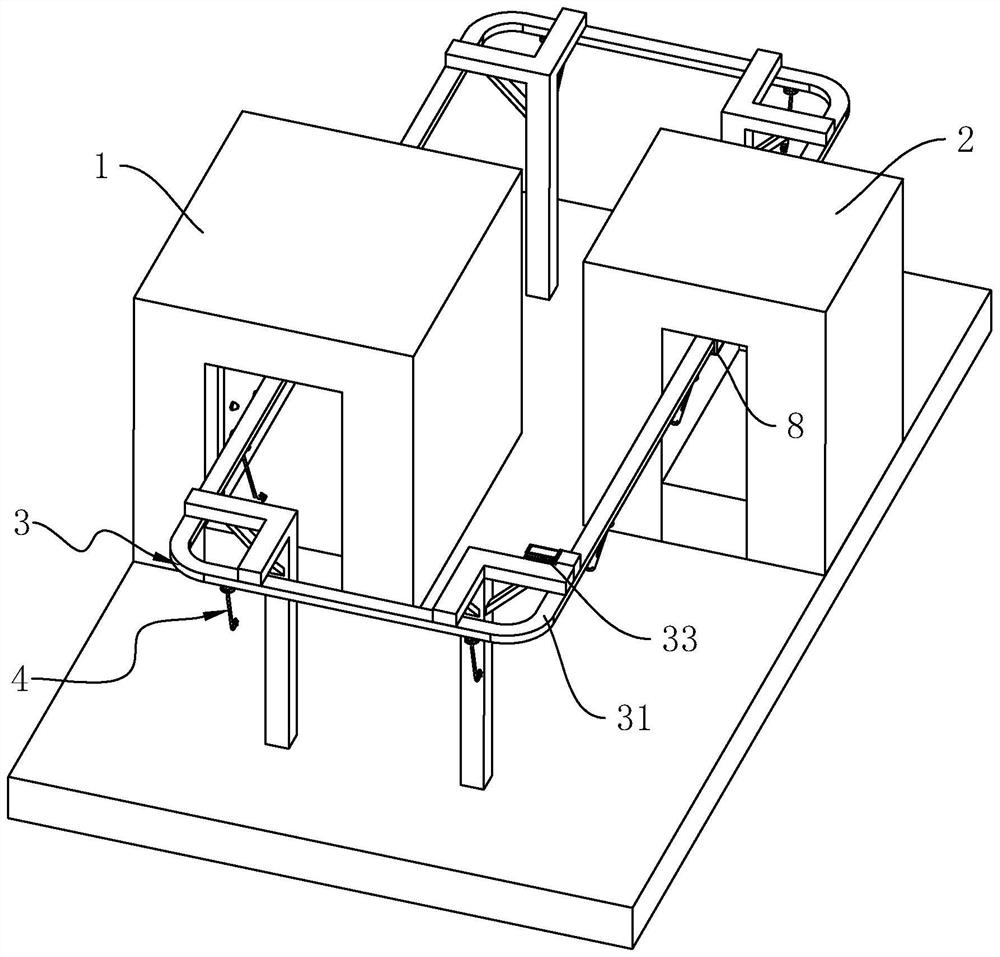

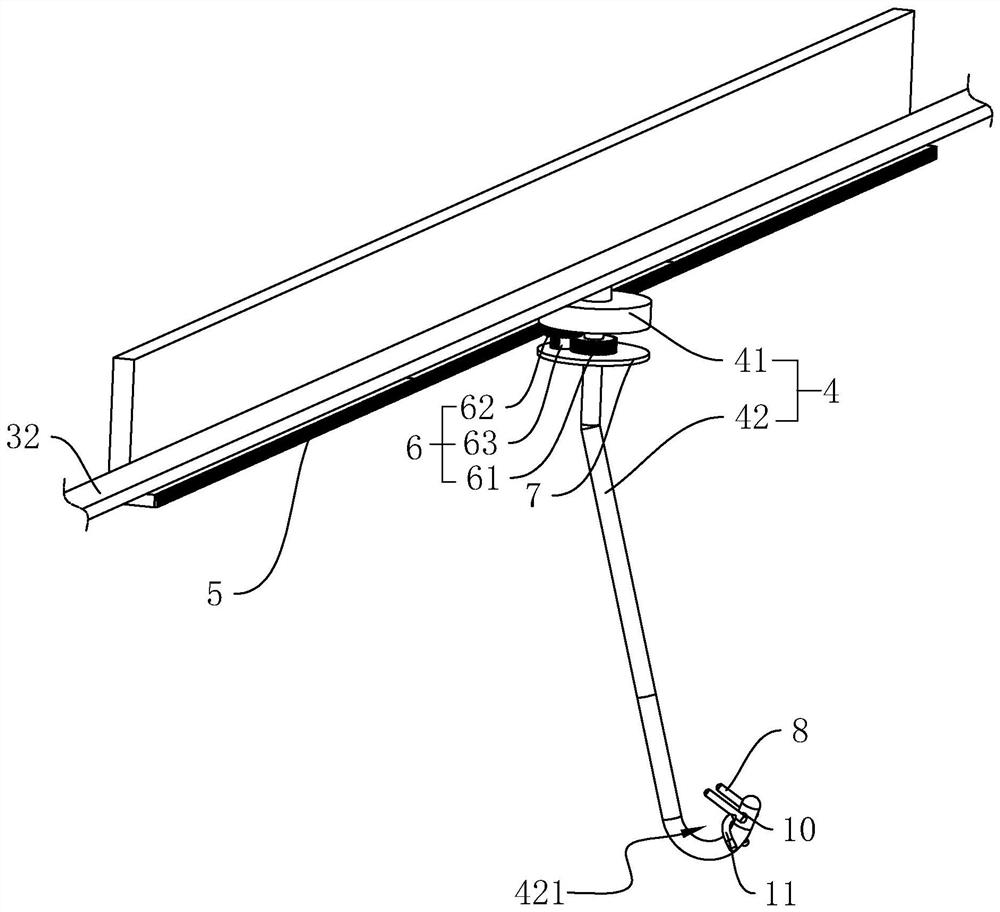

[0039] The following is attached Figure 1-3 The application is described in further detail.

[0040] The embodiment of the present application discloses an automatic spraying production line, such as figure 1 As shown, it includes a paint spraying room 1, a drying room 2 and a hanging conveyor 3. Several painting units are arranged in the painting booth 1, and the painting unit is a spraying machine, which is a prior art, and is a kind of coating equipment that disperses the paint into mist and sprays it on the surface of the object to be coated. The heating of the drying chamber 2 is generally realized after the heating tube is energized, and in some cases, a heat-conducting runner is used in the drying chamber 2, and the heat-conducting runner is made of a heat-conducting material, such as copper. In actual use, heating is realized by passing hot steam in the heat conduction runner. The drying chamber 2 is mainly used for baking the sprayed workpiece so that the sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com