Heat conduction and insulation composite material with anisotropic structure and preparation method of heat conduction and insulation composite material

A technology of heat conduction insulation and composite materials, which is applied in the field of heat conduction insulation composite materials and their preparation, which can solve the problems of not meeting the heat dissipation needs of electronic systems, high thermal expansion coefficient, and restricting applications, and achieve short preparation cycle, high thermal conductivity, and improved heat conduction performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment prepares thermally conductive and insulating composite material (graphene accounts for 0.2% of the mass of the silicone rubber matrix) as follows:

[0032] First, accurately weigh 0.044g of surface-modified graphene, add it to 10mL dispersant 1,4-dioxane, disperse it ultrasonically for 30min, then add 20g of PDMS A component, stir evenly for 10min, disperse ultrasonically for 30min, then add 2g of PDMS B component, sonicate until the dispersant is completely volatilized to obtain a mixture;

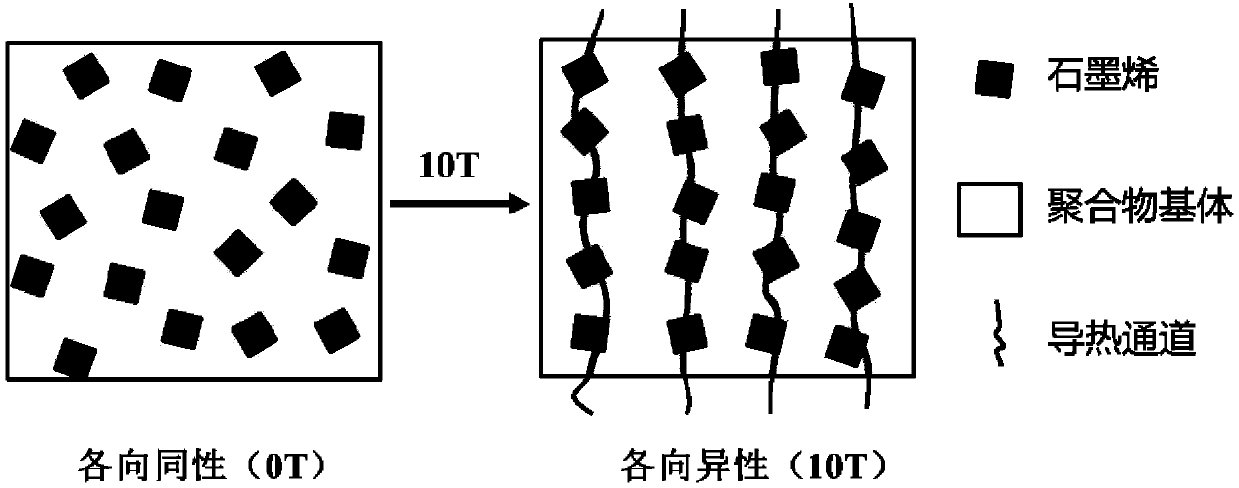

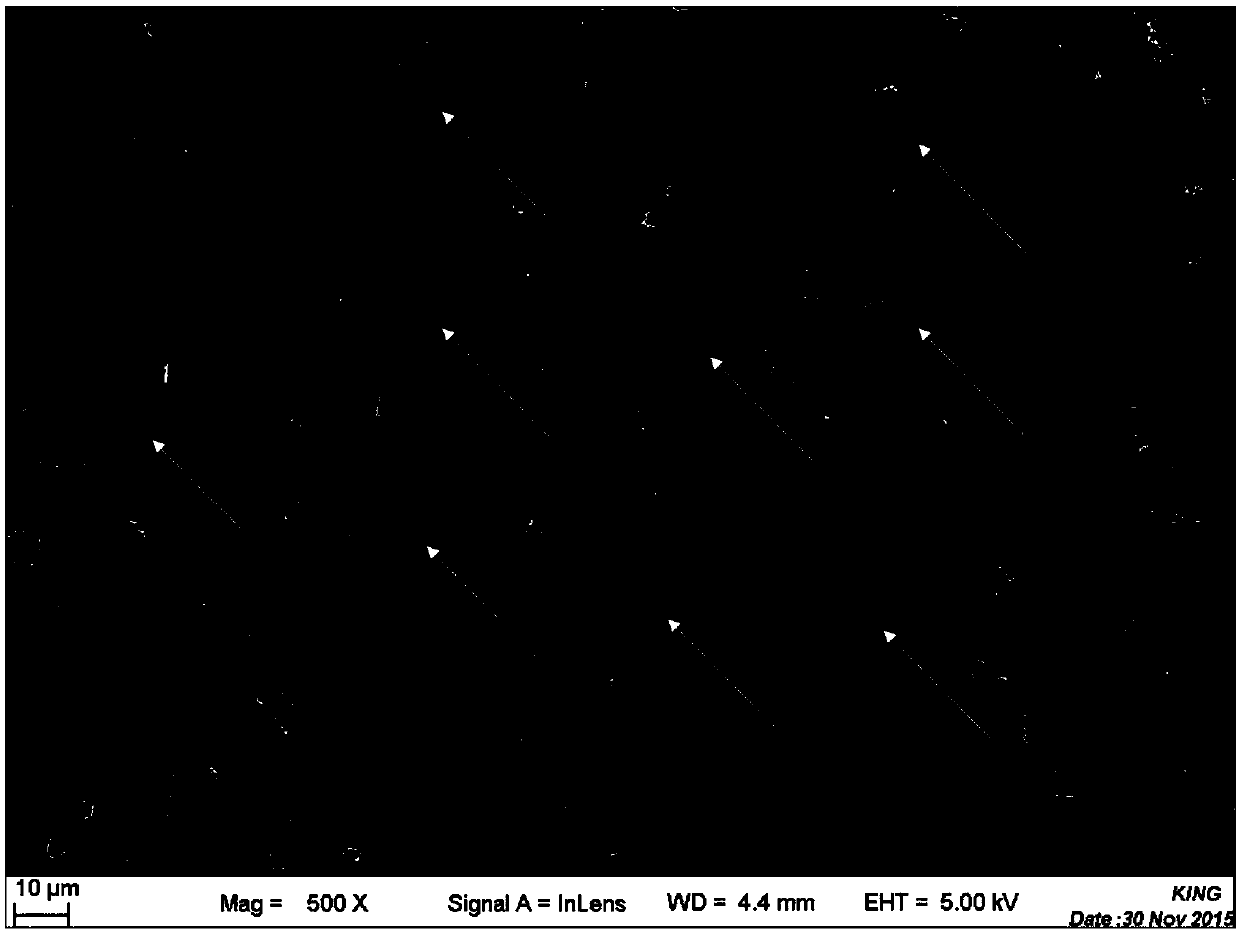

[0033] Vacuumize to remove the air bubbles in the mixture, then pour it into a mold, and cure it at 80°C for 2 hours under a 10T strong magnetic field, so that the graphene is arranged in the matrix to form a chain structure, thereby forming an anisotropic heat conduction channel, and the target product is obtained Thermally conductive and insulating composite materials.

[0034] figure 1 It is a schematic diagram of the change of the microstructure of the ...

Embodiment 2

[0039] The present embodiment prepares thermally conductive and insulating composite material (graphene accounts for 0.5% of the mass of the silicone rubber matrix) as follows:

[0040]First, accurately weigh 0.11g of surface-modified graphene, add it to 10mL dispersant 1,4-dioxane, disperse it ultrasonically for 30min, then add 20g of PDMS A component, stir evenly for 10min, disperse ultrasonically for 30min, then add 2g of the PDMSB component, sonicated until the dispersant was completely volatilized to obtain a mixture;

[0041] Vacuumize to remove the air bubbles in the mixture, then pour it into a mold, and cure it at 80°C for 2 hours under a 10T strong magnetic field, so that the graphene is arranged in the matrix to form a chain structure, thereby forming an anisotropic heat conduction channel, and the target product is obtained Thermally conductive and insulating composite materials.

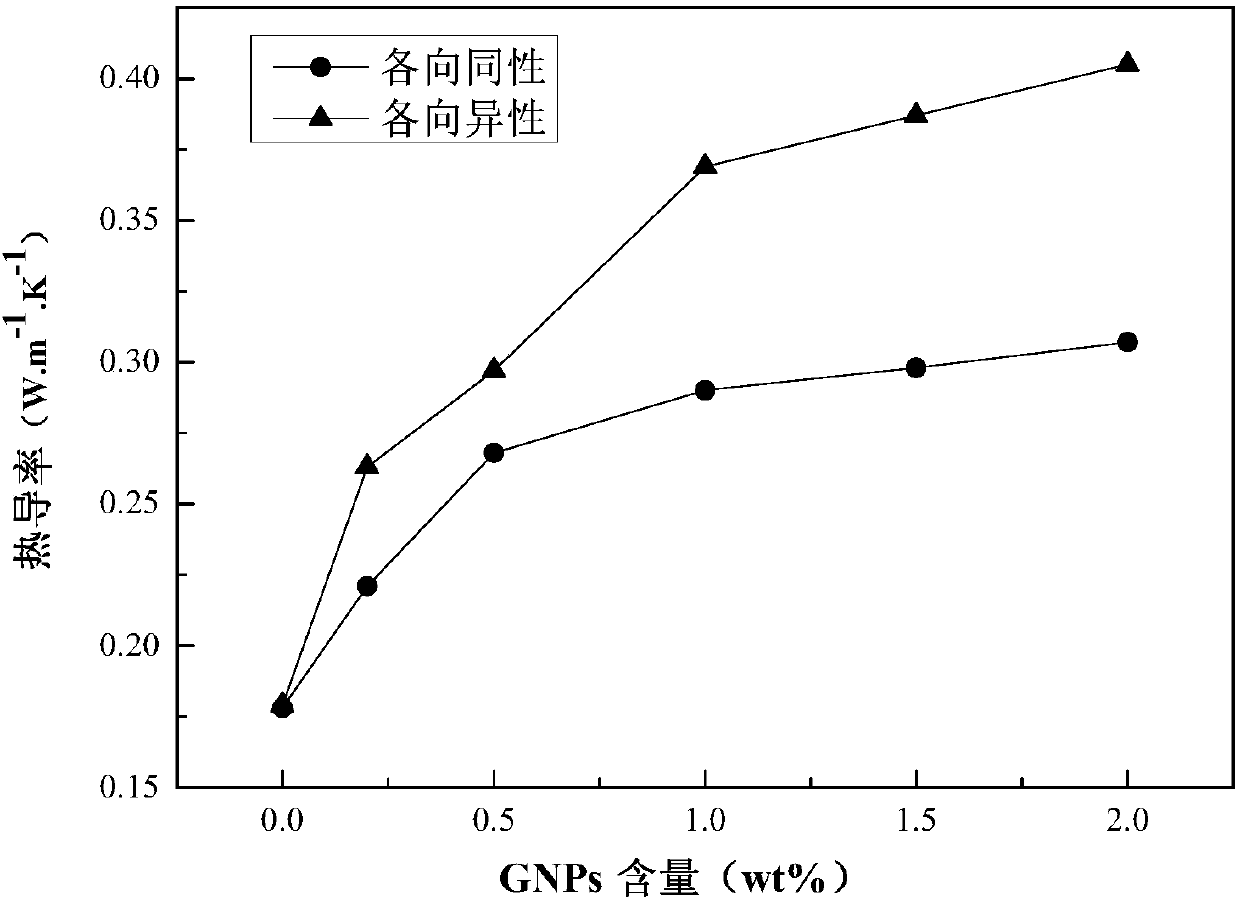

[0042] In order to compare the effect of the anisotropic structure on the performan...

Embodiment 3

[0045] The present embodiment prepares thermally conductive and insulating composite material (graphene accounts for 1.0% of the quality of the silicone rubber matrix) as follows:

[0046] First, accurately weigh 0.22g of surface-modified graphene, add it to 10mL dispersant 1,4-dioxane, and disperse it ultrasonically for 30min, then add 20g of PDMS A component, stir evenly for 10min, disperse ultrasonically for 30min, then add 2g of the PDMSB component, sonicated until the dispersant was completely volatilized to obtain a mixture;

[0047] Vacuumize to remove the air bubbles in the mixture, then pour it into a mold, and cure it at 80°C for 2 hours under a 10T strong magnetic field, so that the graphene is arranged in the matrix to form a chain structure, thereby forming an anisotropic heat conduction channel, and the target product is obtained Thermally conductive and insulating composite materials.

[0048] In order to compare the effect of the anisotropic structure on the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com