Software definition type control system and method

A control system and software-defined technology, applied in the general control system, control/regulation system, program control in sequence/logic controller, etc., can solve the problem of long development cycle, increased development difficulty, software stability and consistency Variation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

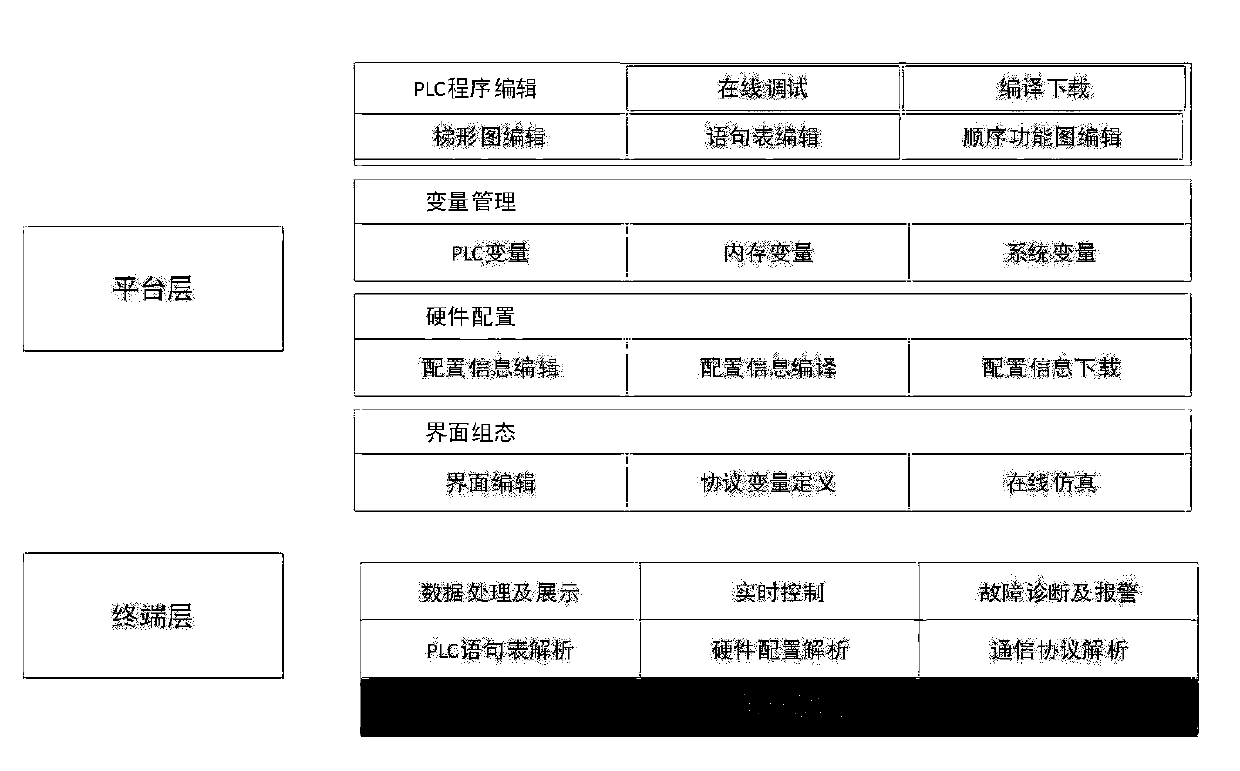

[0083] A software-defined control system, including a platform layer and a terminal layer;

[0084] The platform layer includes a PLC program editing module, a variable management module, a hardware configuration module and an interface configuration module;

[0085] The terminal layer is PLC series hardware, which is used for: data processing and display, real-time control, fault diagnosis and alarm, PLC sentence list analysis, hardware configuration analysis and communication protocol analysis.

[0086] For example, the terminal layer is Shanke PLC series hardware. The Shanke PLC series hardware (SKPLC for short) is a Shanke brand PLC product with independent intellectual property rights developed by the Shandong Provincial Computing Center affiliated to the Shandong Academy of Sciences.

[0087] The platform layer includes a core processing unit, an input and output module connected to the core processing unit, a communication module, a human-computer interaction module an...

Embodiment 2

[0090] A software-defined control system as described in Embodiment 1, the difference is that the core processing unit adopts an ARM-based microcontroller LPC2368; the functional interface is rich, and the performance is stable and reliable;

[0091] The input and output module is used for: digital input and output, analog input and output, high-speed pulse input and output;

[0092] The communication module is used for: realizing the communication between the platform layer and the terminal layer;

[0093] The human-computer interaction module is used for: displaying data read from the PLC, data analysis results, and alarm signals on the interface, and realizing parameter setting and manual control of the touch screen through the interface.

[0094] The power management module is used for supplying power to the platform layer and the terminal layer respectively.

[0095] The input and output module includes: switch input, switch output, analog input, analog output, high-spee...

Embodiment 3

[0099] A software-defined control system as described in Embodiments 1 and 2 is characterized in that it includes:

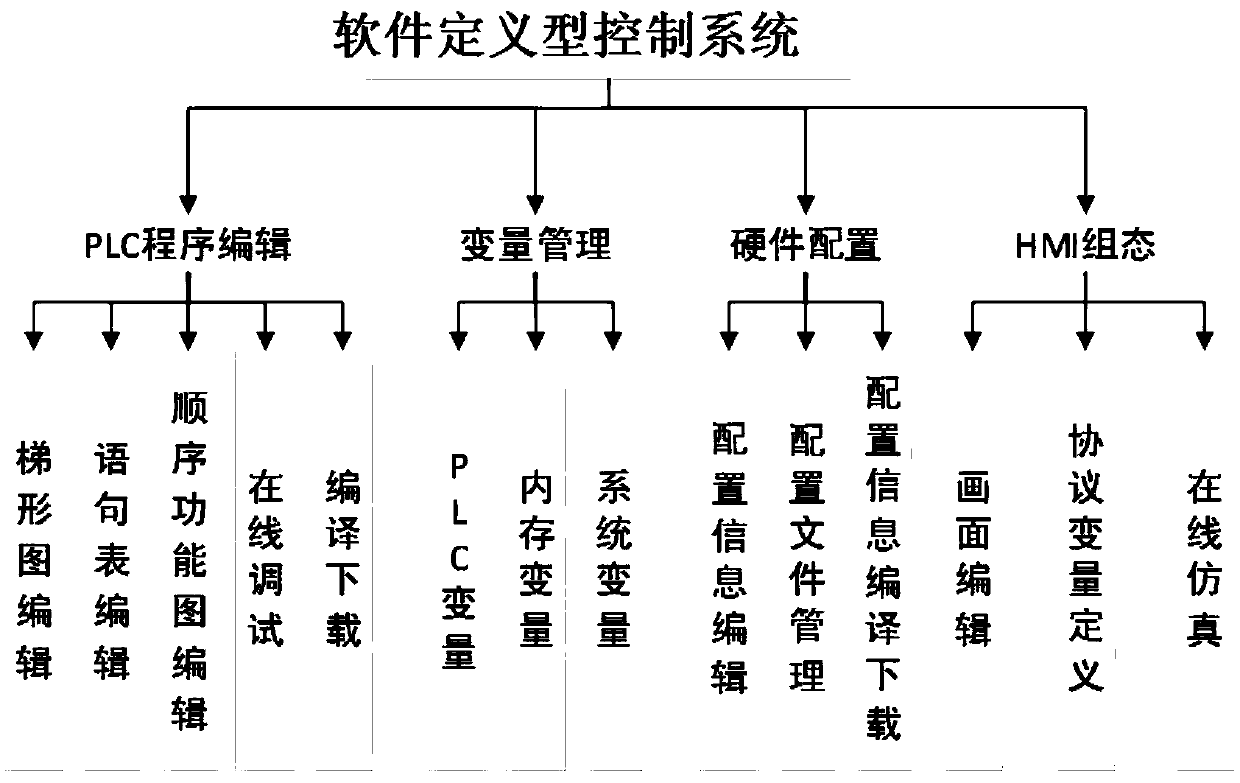

[0100] PLC program editing, variable management, hardware configuration and HMI configuration;

[0101] The PLC program editing is used to: realize the online editing and compiling functions of the PLC software; the PLC software editing interface is divided into three parts: a ladder diagram editor, a statement list editor and a sequential function diagram editor, which can realize ladder diagram / sequential function diagram Drawing, sentence list editing and conversion between the three functions, and also realize online debugging, serial port setting, serial port compilation and downloading functions. PLC software editing interface such as Figure 4 Shown:

[0102] The variable management is used for: viewing and editing PLC variables, memory variables and system variables; specifically, adding and customizing the names of editable PLC variables, memory varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com