SPR (Surface Plasmon Resonance) based photonic crystal fiber temperature sensor

A technology of photonic crystal fiber and temperature sensor, which is applied in the direction of physical/chemical change thermometers, thermometers, instruments, etc., which can solve the problem of low application range and temperature sensitivity of fiber-optic SPR temperature sensors, and relatively large changes in the original structure of photonic crystal fibers. Large size, insufficient sensitivity improvement, etc., to meet the requirements of light source bandwidth and signal strength, simple structure, and high signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] By referring to the exemplary embodiments, the technical problems, technical solutions and advantages of the present invention will be clarified. However, the present invention is not limited to the exemplary embodiments disclosed below; it can be implemented in various forms. The essence of the description is only to help those skilled in the relevant art comprehensively understand the specific details of the present invention.

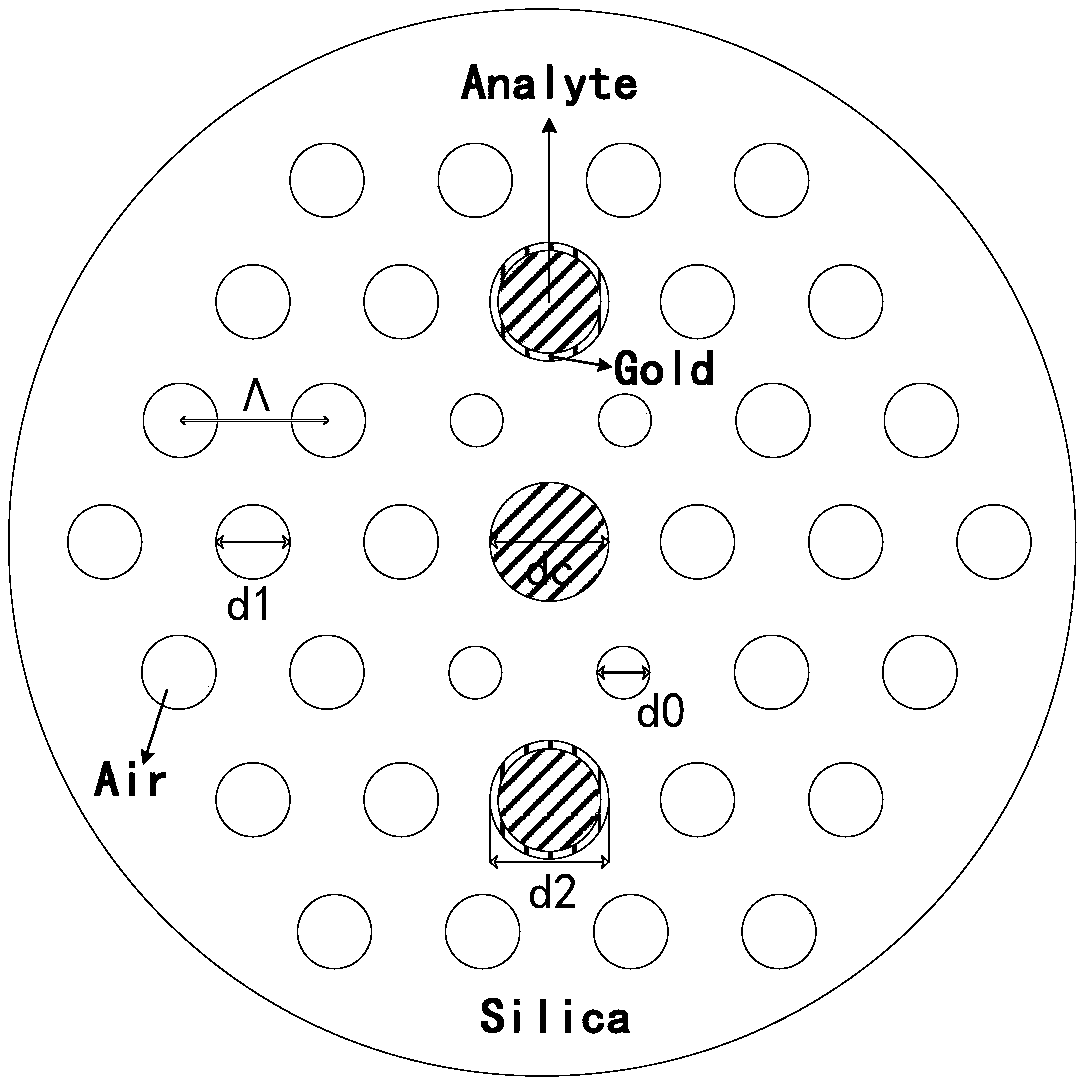

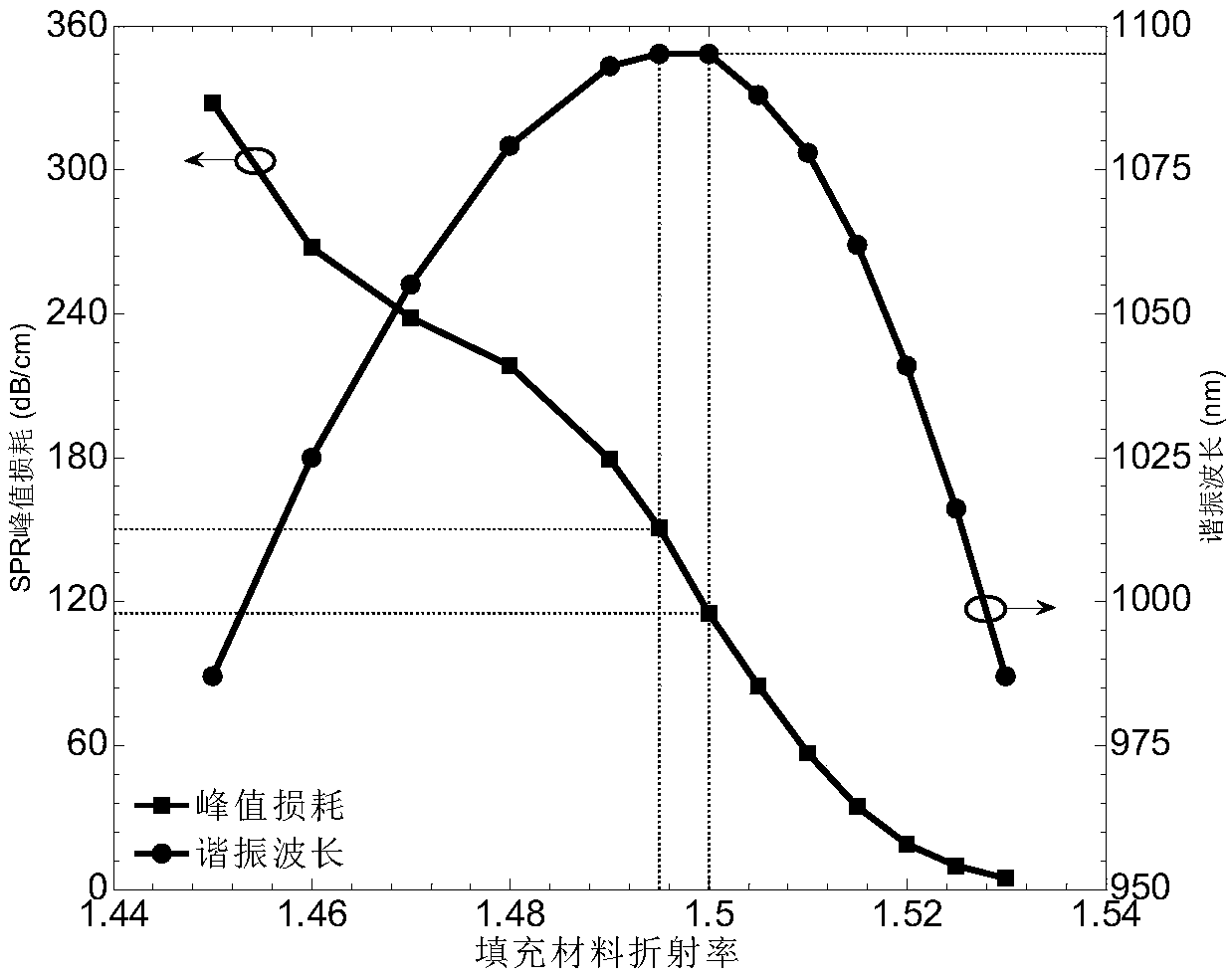

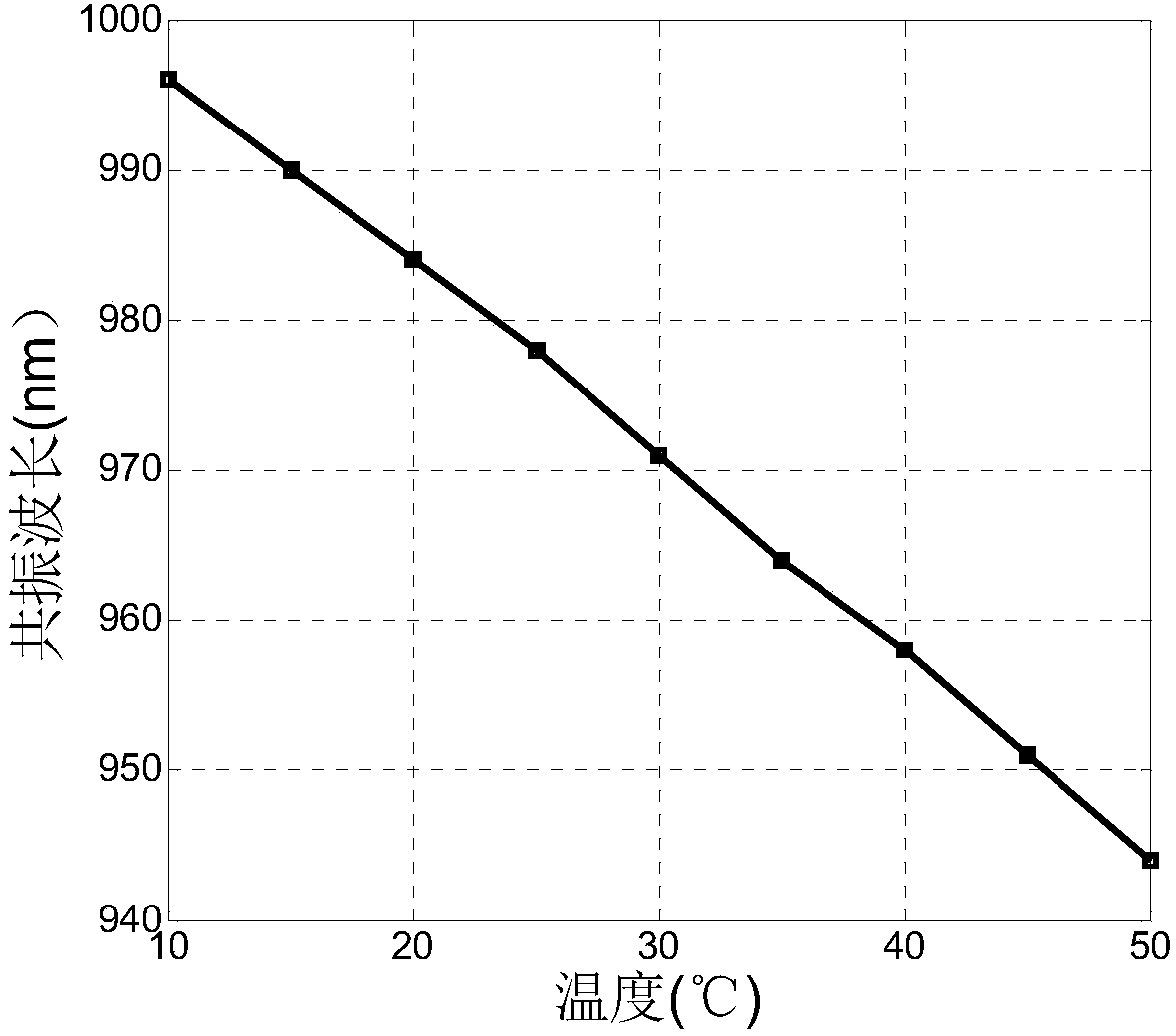

[0019] The photonic crystal optical fiber temperature sensor based on the surface plasmon resonance (Surface Plasmon Resonance, SPR) technology of the present invention adopts technical means such as multi-metal channels, filling high thermo-optic coefficient materials and the like to enhance the sensitivity of the optical fiber to temperature. The SPR phenomenon is formed by coating the air hole originally existing in the optical fiber temperature sensor with a metal film. At the same time, the sensitivity of the SPR phenomenon to the refract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com