A Feedforward Control Electronically Controlled Gear Shift System

A feed-forward control and electronic control technology, which is applied in the direction of transmission control, toothed components, clutches, etc., can solve the mutual influence of clutch oil filling time and gear pressure boost time, slow gear boost, and gear Improve driving comfort, reduce the impact of gear shifting, and achieve flexible matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

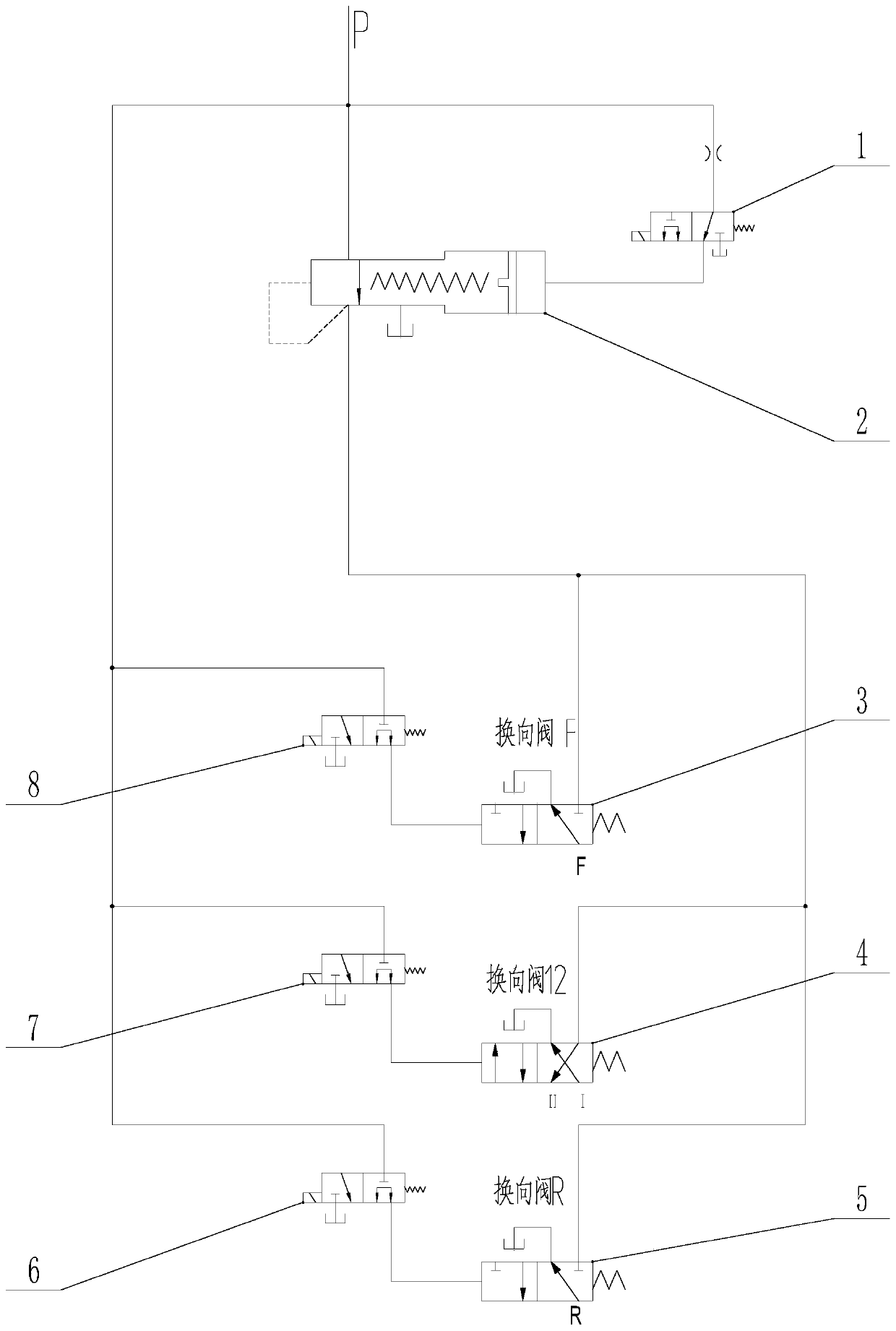

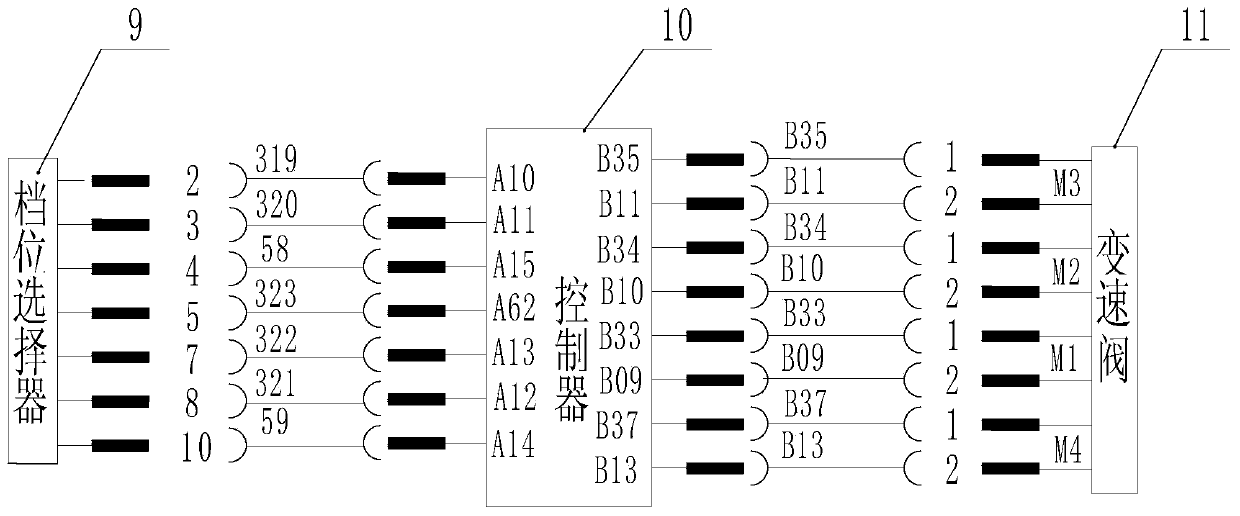

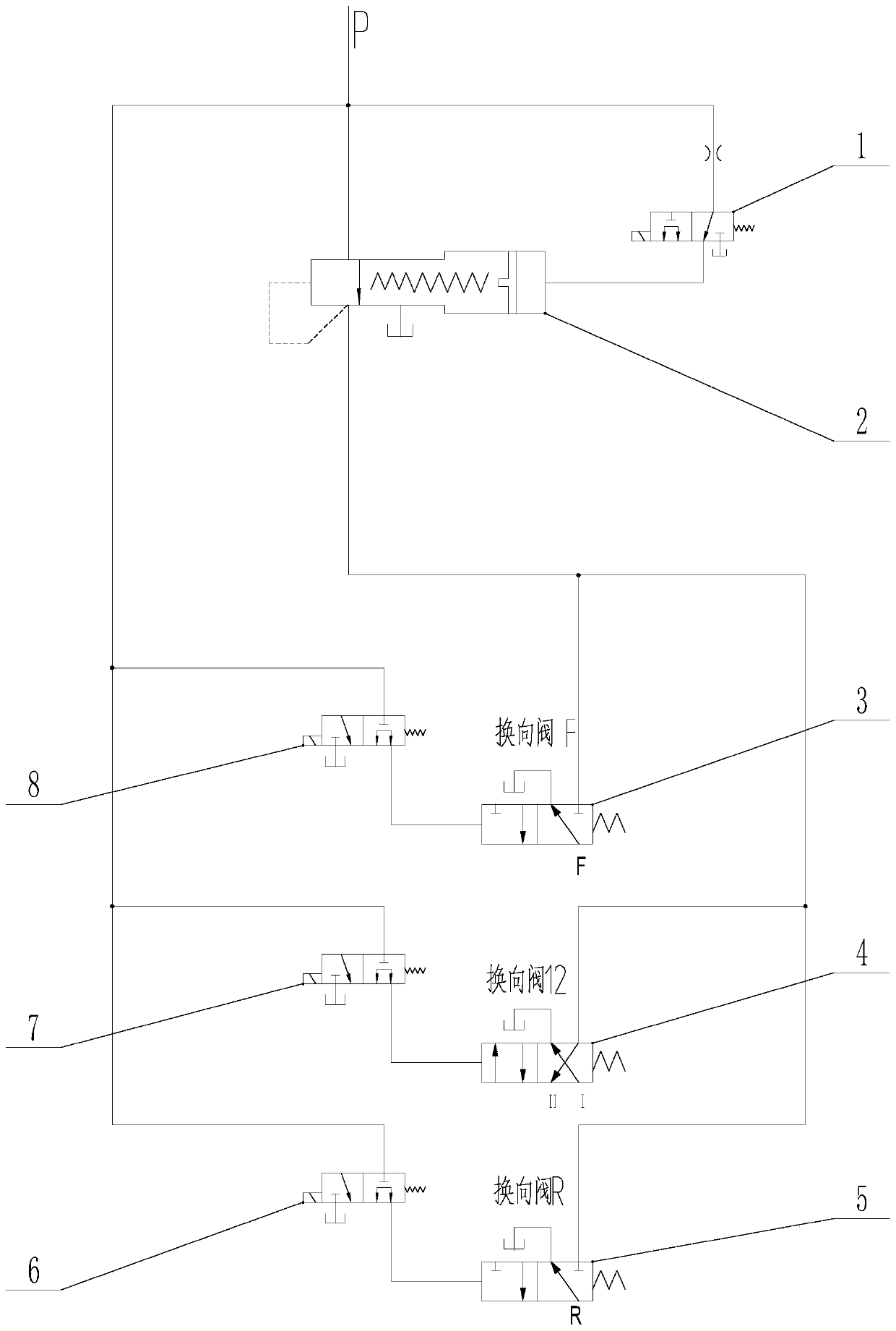

[0019] Such as figure 1 and figure 2 As shown, the feed-forward controlled electronically controlled shifting system includes a gear selector 9, a controller 10, and a shift valve 11. The gear selector 9 is provided with a reversing valve, and the gear selector 9 and the shift valve 11 They are respectively connected to the controller 10. The speed change valve 11 is provided with a time control solenoid valve 1. The time control solenoid valve 1 is connected to the reversing valve through the pressure regulating valve 2. The controller 10 controls the pressure regulating valve 2 through the time control solenoid valve 1. Side pressure source.

[0020] Such as figure 2 As shown, the reversing valve includes a forward gear reversing valve 3, a 1 / 2 gear reversing valve 4 and a reverse gear reversing valve 5; the transmission valve 11 is provided with a forward gear solen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com