Combined heat and power generation system for condensing-extracting-backpressure heat supply and operation method thereof

A technology of combined heat and power generation and heat network, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of unit working capacity loss, high heating and steam extraction pressure, and increase, so as to reduce the working capacity loss , reduce exhaust parameters, reduce the effect of heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

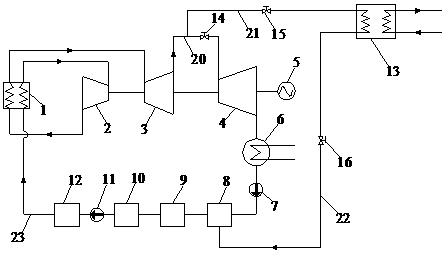

[0024] see Figure 1 to Figure 3 , in this embodiment, a cogeneration system for condensing and pumping back heating, which includes: boiler 1, steam turbine high-pressure cylinder 2, steam turbine medium-pressure cylinder 3, steam turbine low-pressure cylinder 4, generator 5, condensing steam 6, condensate pump 7, low-pressure heater 8, feedwater heater 9, deaerator 10, feedwater pump 11, high-pressure heater 12 and heat network heat exchanger 13; the steam inlet of the high-pressure cylinder 2 of the steam turbine and the boiler The main steam port of 1 is connected, the exhaust port of the high-pressure cylinder 2 of the steam turbine is connected with the reheat steam inlet of boiler 1, the reheat steam outlet of boiler 1 is connected with the steam inlet of the medium-pressure cylinder 3 of the steam turbine, and the medium-pressure cylinder of the steam turbine The steam exhaust port of 3 is connected with the steam inlet of the steam turbine low-pressure cylinder 4 thro...

Embodiment 2

[0036] see figure 1 , The combined heat and power system includes: boiler 1, steam turbine high pressure cylinder 2, steam turbine medium pressure cylinder 3, steam turbine low pressure cylinder 4, generator 5, condenser 6, condensate water pump 7, low heating heater 8, feed water heater 9, Deaerator 10, feed water pump 11, high heating heater 12 and heat network heat exchanger 13; the steam inlet of steam turbine high-pressure cylinder 2 is connected to the main steam port of boiler 1, and the steam exhaust port of steam turbine high-pressure cylinder 2 is connected to boiler 1 The reheat steam inlet of the boiler 1 is connected to the steam inlet of the medium pressure cylinder 3 of the steam turbine, and the exhaust port of the medium pressure cylinder 3 of the steam turbine is connected to the steam inlet of the low pressure cylinder 4 of the steam turbine through the connecting pipe 20 connected, and a steam regulating valve 14 is installed on the communication pipe 20, t...

Embodiment 3

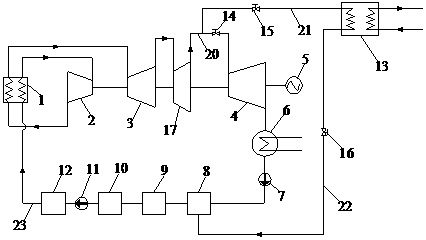

[0040] see figure 2 , The combined heat and power system includes: boiler 1, steam turbine high pressure cylinder 2, steam turbine medium pressure cylinder 3, steam turbine low pressure cylinder 4, generator 5, condenser 6, condensate water pump 7, low heating heater 8, feed water heater 9, Deaerator 10, feed water pump 11, high heating heater 12 and heat network heat exchanger 13; the steam inlet of steam turbine high-pressure cylinder 2 is connected to the main steam port of boiler 1, and the steam exhaust port of steam turbine high-pressure cylinder 2 is connected to boiler 1 The reheat steam inlet of the boiler 1 is connected to the steam inlet of the medium pressure cylinder 3 of the steam turbine, and the exhaust port of the medium pressure cylinder 3 of the steam turbine is connected to the steam inlet of the low pressure cylinder 4 of the steam turbine through the connecting pipe 20 connected, and a steam regulating valve 14 is installed on the communication pipe 20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com