A kind of preparation method of antibacterial active packaging film loaded with cinnamaldehyde essential oil

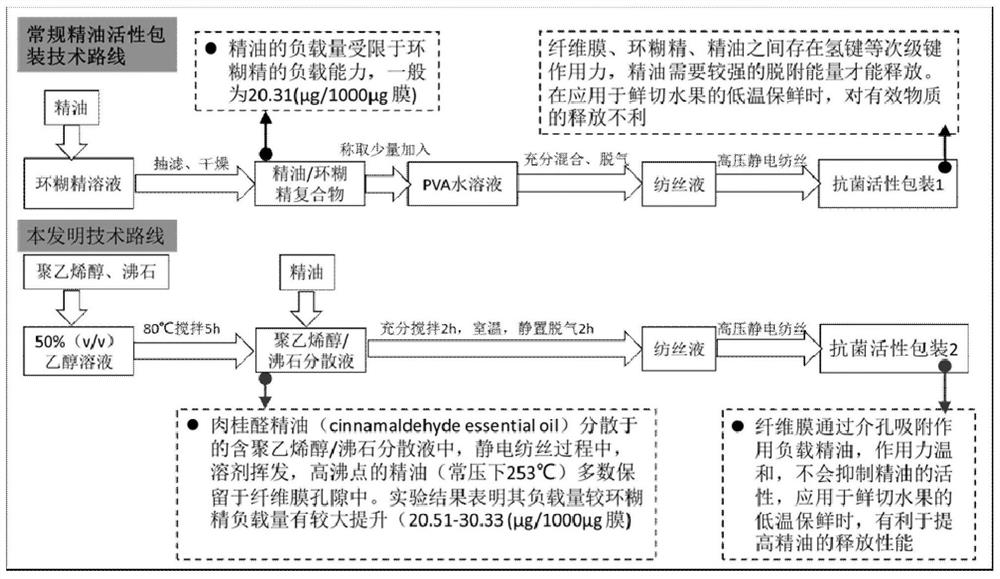

A technology of cinnamaldehyde essential oil and antibacterial activity is applied in the field of preparation of antibacterial active packaging films, which can solve the problems of high requirements, small β-cyclodextrin loading, affecting the release performance of essential oils, etc., and achieves enhanced tensile strength and convenient release. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

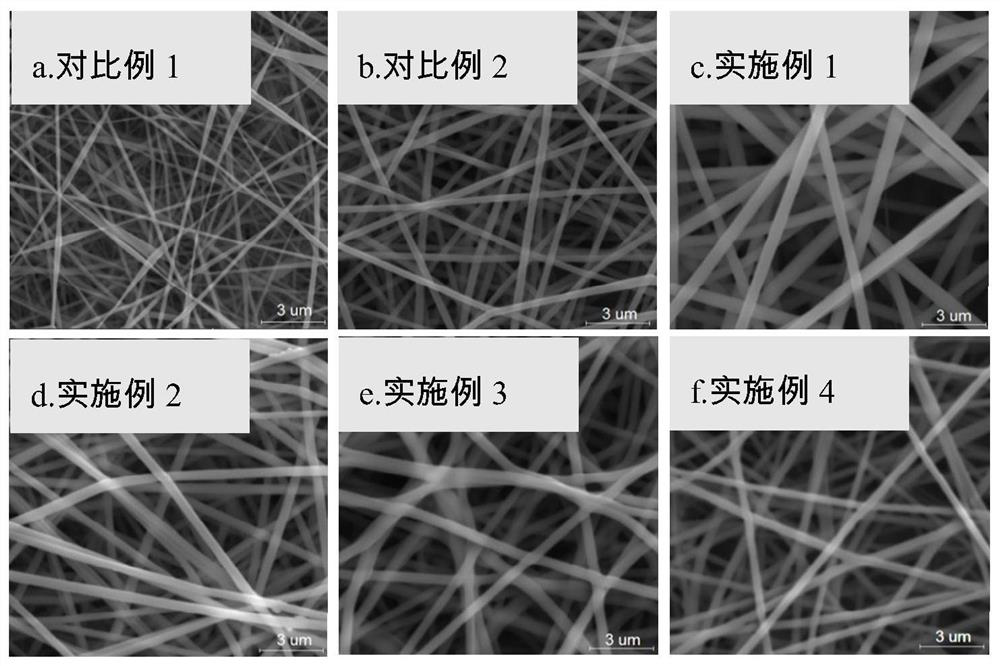

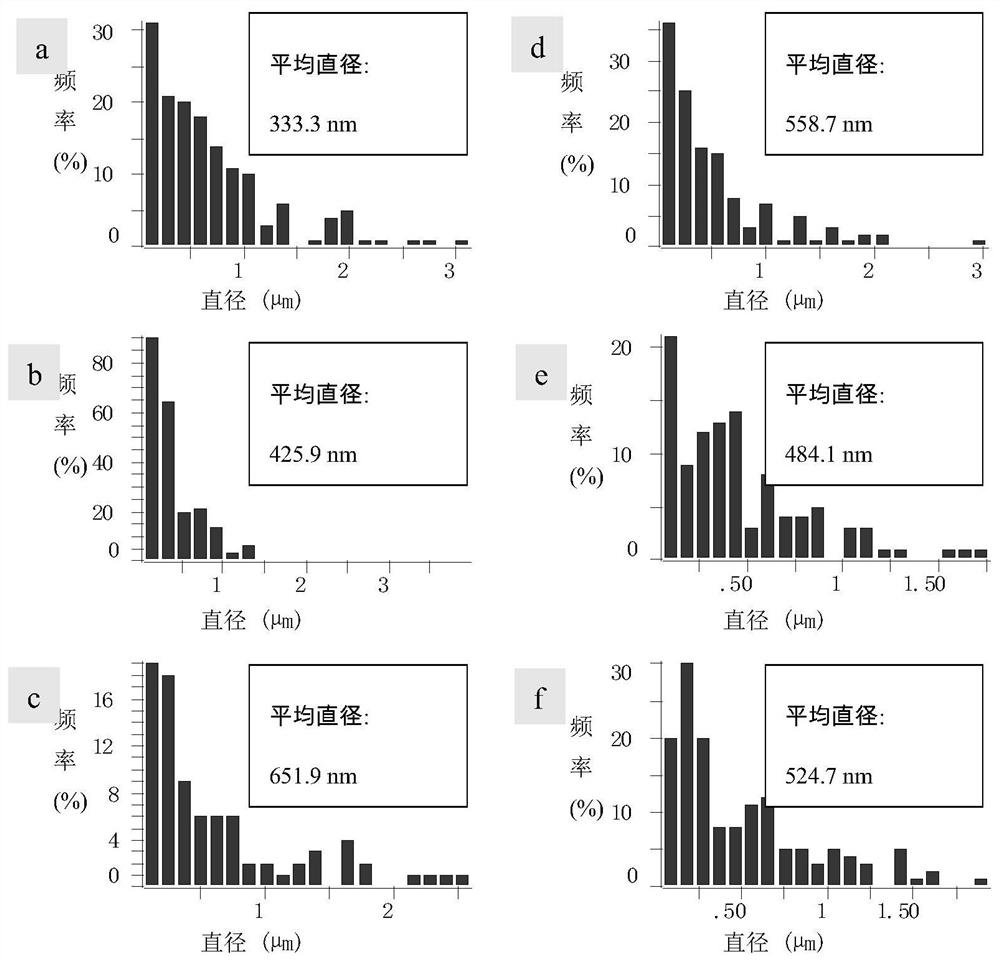

Embodiment 1

[0041] Take 20 mL of a mixed solvent obtained by dehydrated ethanol and purified water at a ratio of 1:1 by volume, weigh 2.0 g of polyvinylalcohol (PVA) and 0.2 g of zeolite into the mixed solvent, and perform magnetic stirring at 80° C. for 8 h (Little Tony, IKA, Germany) to obtain a polyvinyl alcohol / zeolite dispersion. Add 0.25 mL of cinnamaldehyde essential oil to the polyvinyl alcohol / zeolite dispersion, continue to stir for 2 hours until it becomes translucent milky white, stop stirring, and let it stand at room temperature for 2 hours to remove small bubbles in the solution to obtain spinning solution B.

[0042] The above-mentioned spinning solution B was taken to carry out electrospinning to prepare ultrafine fiber membranes, and the spinning parameters were: voltage: 12KV, needle type: 18G, polar distance (distance from the needle to the receiver): 15cm, and the receiver was in the form of a drum. Cover with a layer of aluminum foil paper for food, the speed is 100r...

Embodiment 2

[0044] Take 20 mL of a mixed solvent obtained by dehydrated ethanol and purified water at a ratio of 1:1 by volume, weigh 2.0 g of polyvinylalcohol (PVA) and 0.2 g of zeolite into the mixed solvent, and perform magnetic stirring at 80° C. for 8 h (Little Tony, IKA, Germany) to obtain a polyvinyl alcohol / zeolite dispersion. After the stirring is completed, add 0.50 mL of cinnamaldehyde essential oil and continue to stir for 2 hours until it becomes translucent and milky white, then stop stirring and let stand at room temperature for 2 hours to remove small bubbles in the solution to obtain spinning solution B.

[0045] The above-mentioned spinning solution is taken to carry out electrospinning to prepare ultrafine fiber membranes. The spinning parameters are: voltage: 13KV, needle type: 18G, pole distance (distance from needle to receiver): 15cm, receiver is in the form of a drum, and coated A layer of aluminum foil paper for food, the rotating speed is 100r / min, the spinning l...

Embodiment 3

[0047] Take 20mL of a mixed solvent obtained by volume 1:1 of absolute ethanol and purified water, weigh 2.0g of polyvinylalcohol (PVA) and 0.2g of zeolite into the mixed solution, and carry out magnetic stirring at 92°C for 8h (Little Tony, IKA, Germany) to obtain a polyvinyl alcohol / zeolite dispersion. After the stirring is completed, add 0.75 mL of cinnamaldehyde essential oil and continue to stir for 2 hours until it becomes translucent and milky white, then stop stirring and let stand at room temperature for 2 hours to remove small bubbles in the solution to obtain spinning solution B.

[0048] Take the above-mentioned spinning solution B and carry out electrospinning to prepare ultra-fine fiber membranes. The spinning parameters are: voltage: 13KV, needle type: 18G, polar distance (distance from the needle to the receiver): 15cm, and the receiver is in the form of a drum. Cover with a layer of aluminum foil paper for food, the speed is 100r / min, the spinning liquid propu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com