Titanium liquid hydrolyzing device with intubation tubes

A hydrolysis device and titanium liquid technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of insufficient treatment, etc., and achieve the effect of improving tail gas treatment capacity and fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

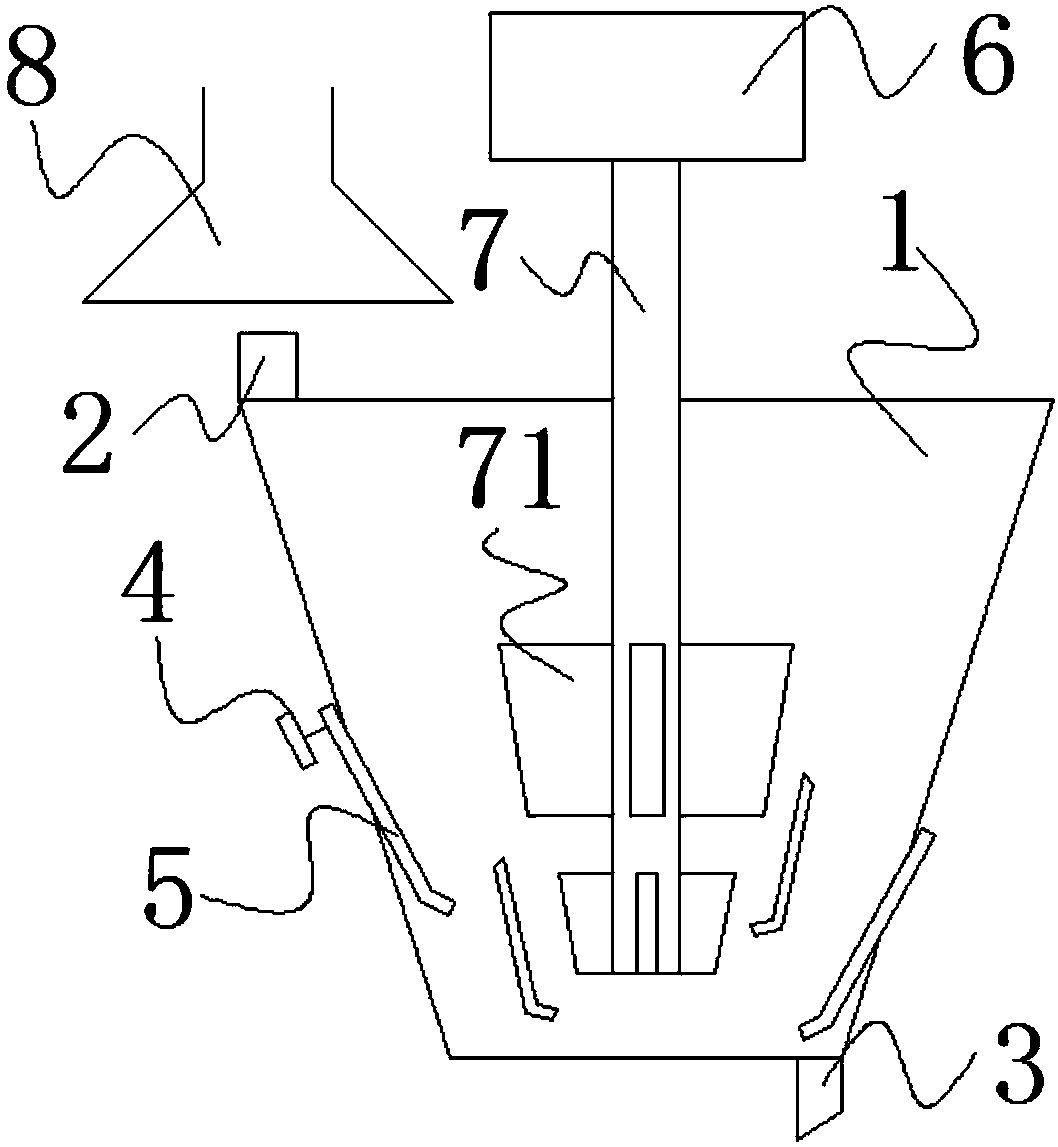

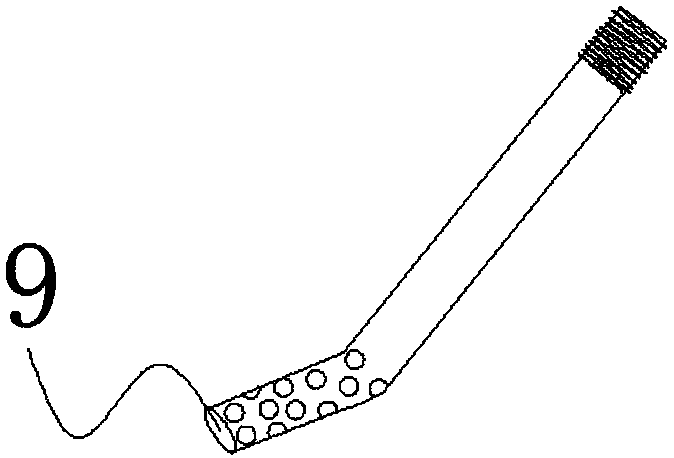

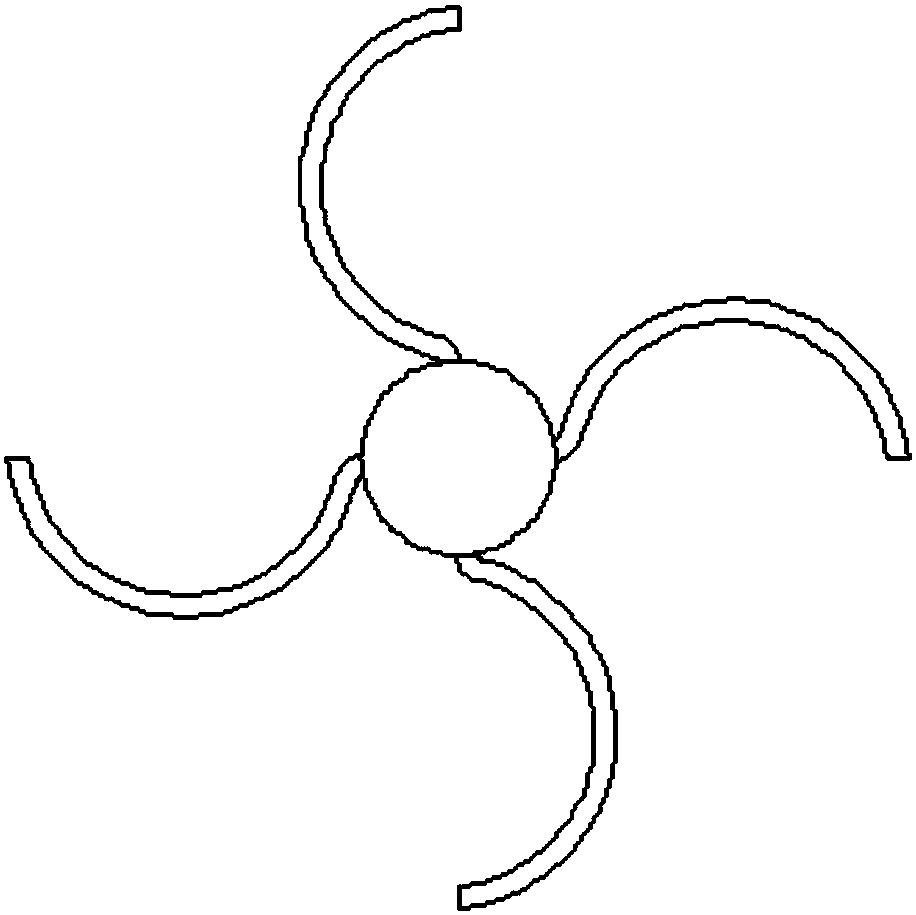

[0018] Such as Figure 1 to Figure 5 As shown, the titanium liquid hydrolysis device with intubation provided in this embodiment includes a hydrolysis container 1, a stirring paddle 7 and a motor 6, the upper end of the stirring paddle 7 is connected to the motor 6 and the lower end is submerged in the cavity of the hydrolysis container 1, so A plurality of steam pipes 5 penetrate obliquely downward on the wall near the bottom of the hydrolysis container 1, and the steam pipes 5 include a straight pipe section and a bent section. There are some fine holes on the surface of the bending section and the end is a steam outlet 9, and the lower end of the stirring paddle 7 is provided with a number of paddles 71, and the paddles 71 are U-shaped plates and one side of the U-shaped side is set horizontally. , the direction of the U-shaped opening of the blade 71 is consistent with the orientation of the corresponding steam outlet 9 .

[0019] The above scheme is the main embodiment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com