Novel IC card automatic truck loading and delivery system and method

An automatic and new technology, applied in packaging, distribution devices, transportation and packaging, etc., can solve the problem of automatic reading, real-time update of delivery orders, no real-time verification of actual loading and weighing data, no system management, etc. problem, to achieve the effect of reducing manual processing links, avoiding cheating, and improving the level of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is a detailed description of the embodiments of the present invention. This embodiment is carried out based on the technical solution of the present invention, and provides detailed implementation methods and specific operation processes.

[0034] A new type of IC card automatic loading and delivery system, including a weighbridge weighing system, a loading system, an IC card, two card readers, two host computers and an ERP server6;

[0035] The schematic diagram of the weighbridge weighing system is as follows figure 1 As shown, including weighbridge 1, video camera 2, and weighing indicator 3.

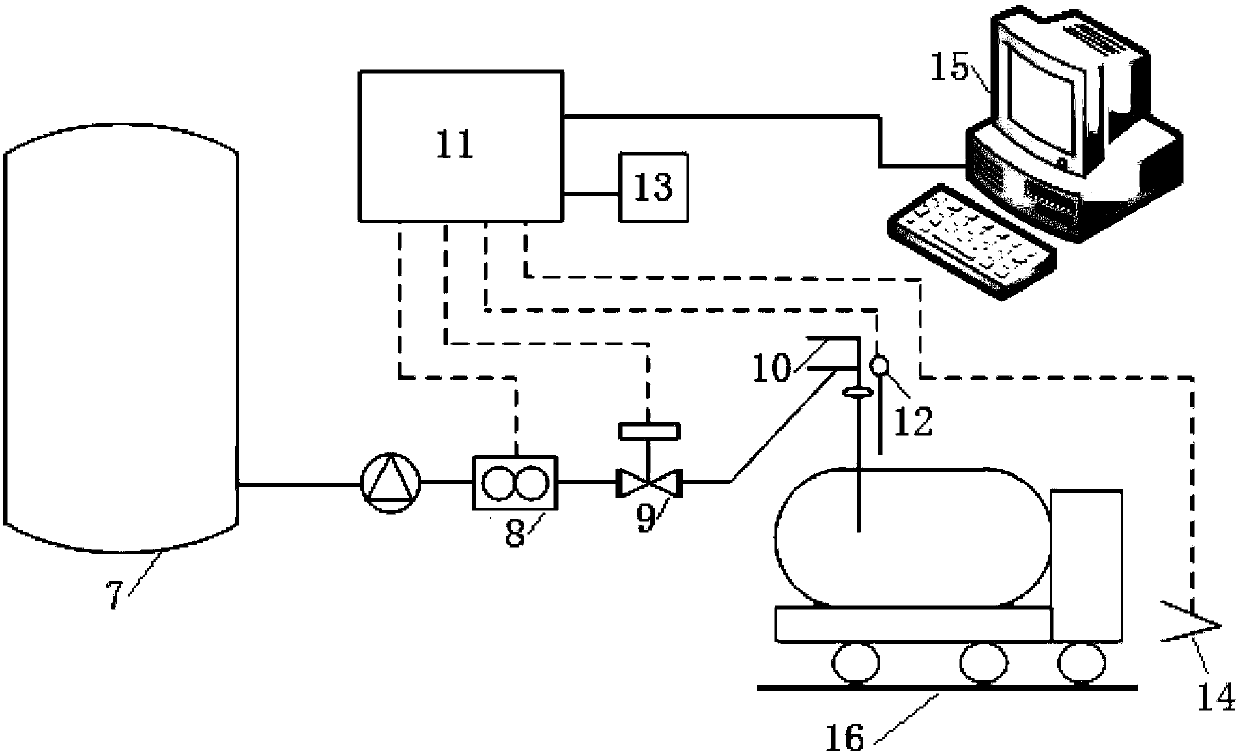

[0036] The schematic diagram of the loading system is as follows: figure 2 As shown, it includes a storage tank 7, a flow meter 8, a control valve 9, a crane pipe 10, a batch controller 11, an oil overflow switch 12, an electrostatic grounding protection switch 14, and a crane position 16.

[0037] A novel IC card automatic loading and delivery method, the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com