Cooling system for five-color printing machine main body

A technology for cooling systems and printing machines, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve the problems of reducing work efficiency and the main engine cooling fluid cannot be replenished, and achieves the effect of stabilizing heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

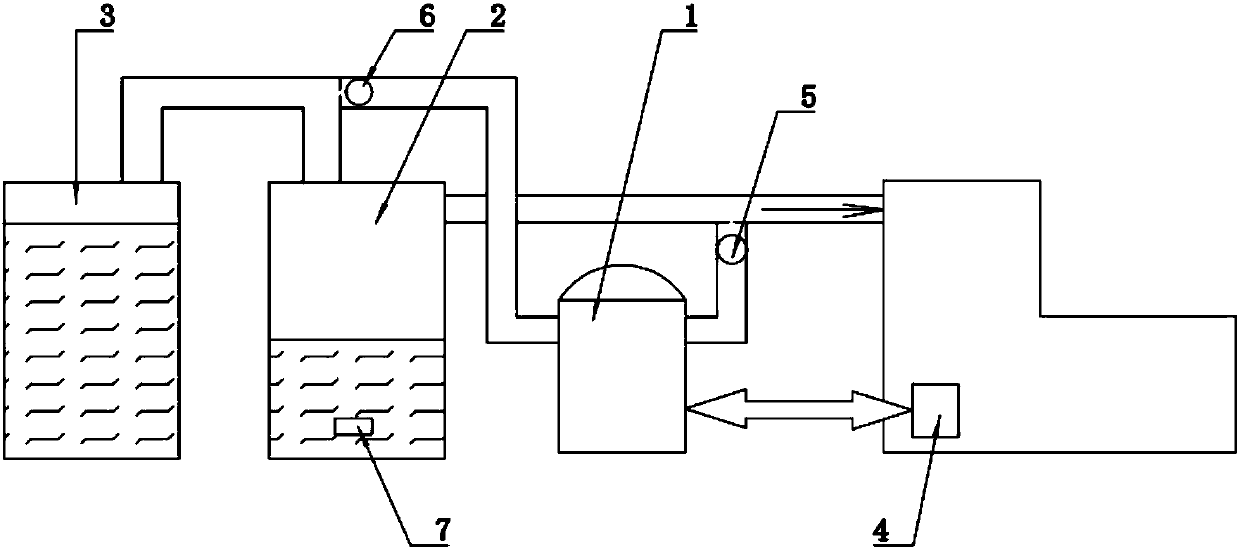

[0023] reference figure 1 .

[0024] The cooling system for the main machine of a five-color printing machine according to the present invention includes a main pump 1 for pumping cooling liquid, a main barrel 2 for storing the cooling liquid of the printing press 2, an auxiliary barrel 3 connected to the main barrel 2, and a main barrel 2 The internal liquid level gauge 7 and the controller 4 connected to the main pump 1 and the liquid level gauge 7, where the liquid level gauge 7 detects that the liquid level of the coolant in the main tank 2 drops to the set position, triggering the coolant from The auxiliary barrel 3 is transported to the main barrel 2. Further, the first solenoid valve 5 arranged on the output path of the main barrel 2 is used to trigger the main barrel 2 to deliver cooling liquid to the main machine of the printing press; the second solenoid valve 6 arranged on the output path of the auxiliary barrel 3 is used to trigger the auxiliary The barrel 3 delivers...

no. 2 example

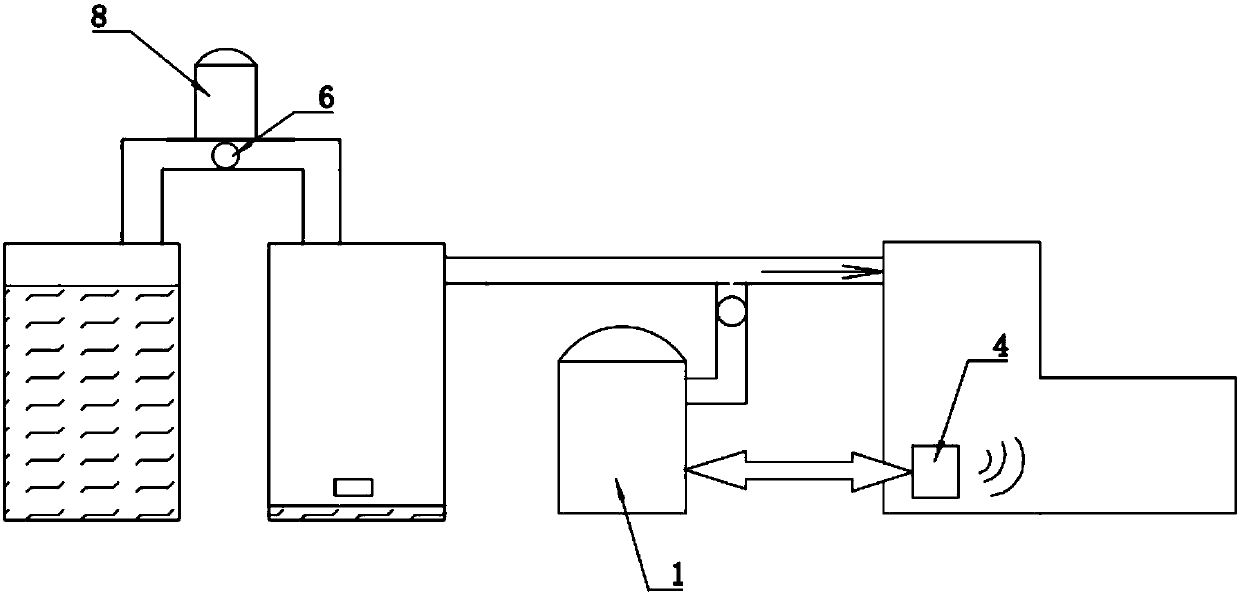

[0027] reference figure 2 .

[0028] The cooling system for the main machine of a five-color printing machine according to the present invention includes a main pump 1 for pumping cooling liquid, a main barrel 2 for storing the cooling liquid of the printing press 2, an auxiliary barrel 3 connected to the main barrel 2, and a main barrel 2 The internal liquid level gauge 7 and the controller 4 connected to the main pump 1 and the liquid level gauge 7, where the liquid level gauge 7 detects that the liquid level of the coolant in the main tank 2 drops to the set position, triggering the coolant from The auxiliary barrel 3 is transported to the main barrel 2. Further, the first solenoid valve 5 arranged on the output path of the main barrel 2 is used to trigger the main barrel 2 to deliver cooling liquid to the main machine of the printing press; the second solenoid valve 6 arranged on the output path of the auxiliary barrel 3 is used to trigger the auxiliary The barrel 3 delive...

no. 3 example

[0031] The cooling system for the main machine of a five-color printing machine according to the present invention includes a main pump 1 for pumping cooling liquid, a main barrel 2 for storing the cooling liquid of the printing press 2, an auxiliary barrel 3 connected to the main barrel 2, and a main barrel 2 The internal liquid level gauge 7 and the controller 4 connected to the main pump 1 and the liquid level gauge 7, where the liquid level gauge 7 detects that the liquid level of the coolant in the main tank 2 drops to the set position, triggering the coolant from The auxiliary barrel 3 is transported to the main barrel 2. Further, the first solenoid valve 5 arranged on the output path of the main barrel 2 is used to trigger the main barrel 2 to deliver cooling liquid to the main machine of the printing press; the second solenoid valve 6 arranged on the output path of the auxiliary barrel 3 is used to trigger the auxiliary The barrel 3 delivers cooling liquid to the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com