Steel pressure pipe longitudinal seam welding and welding seam flaw detection operation device and application method thereof

A pressure steel pipe and longitudinal seam welding technology, which is applied in the direction of welding/welding/cutting articles, auxiliary devices, welding equipment, etc., can solve the problems of welding and flaw detection inspection operation platforms that do not meet the requirements of strength, repeated disassembly and assembly, and the versatility of on-site operation platforms not strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

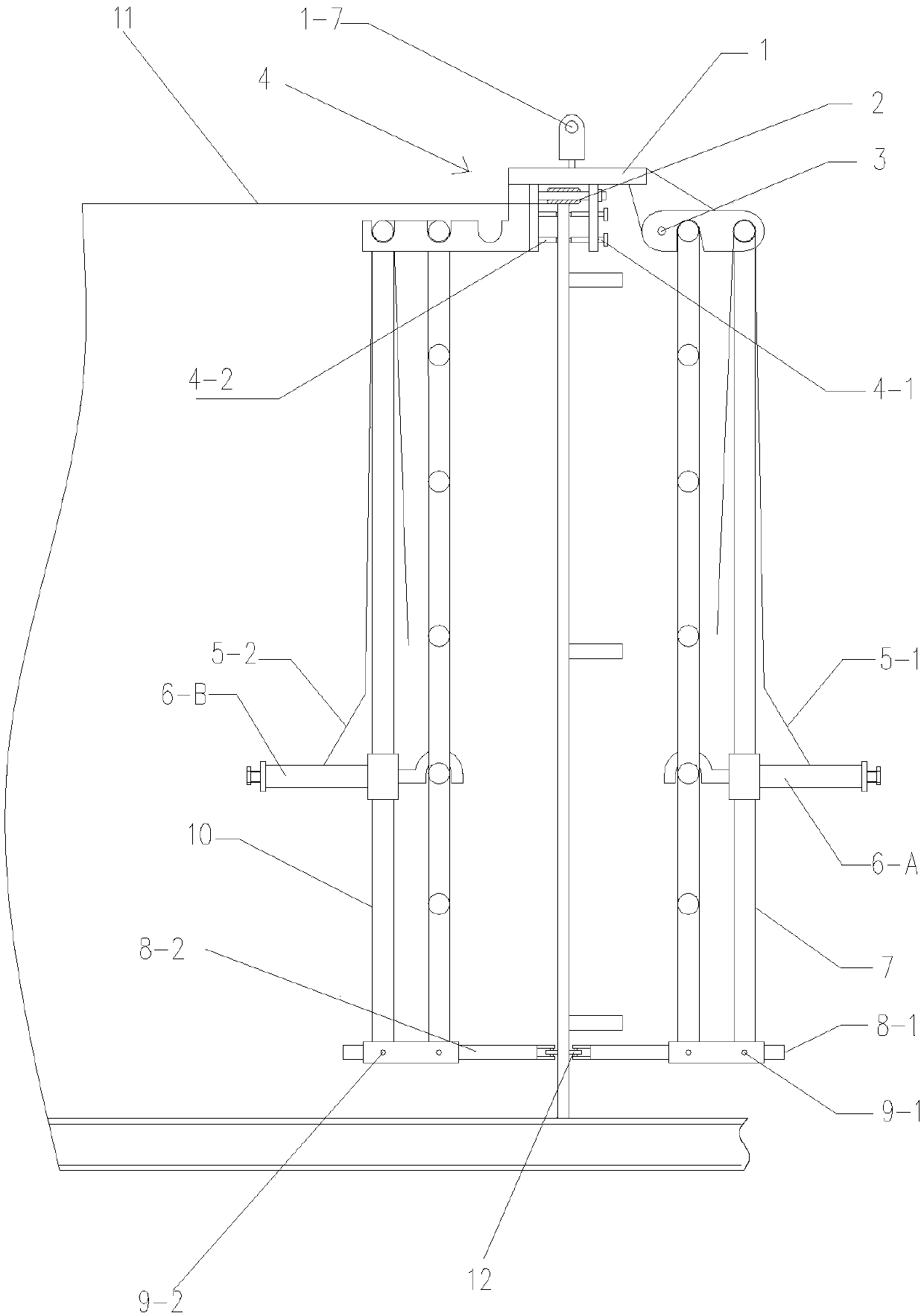

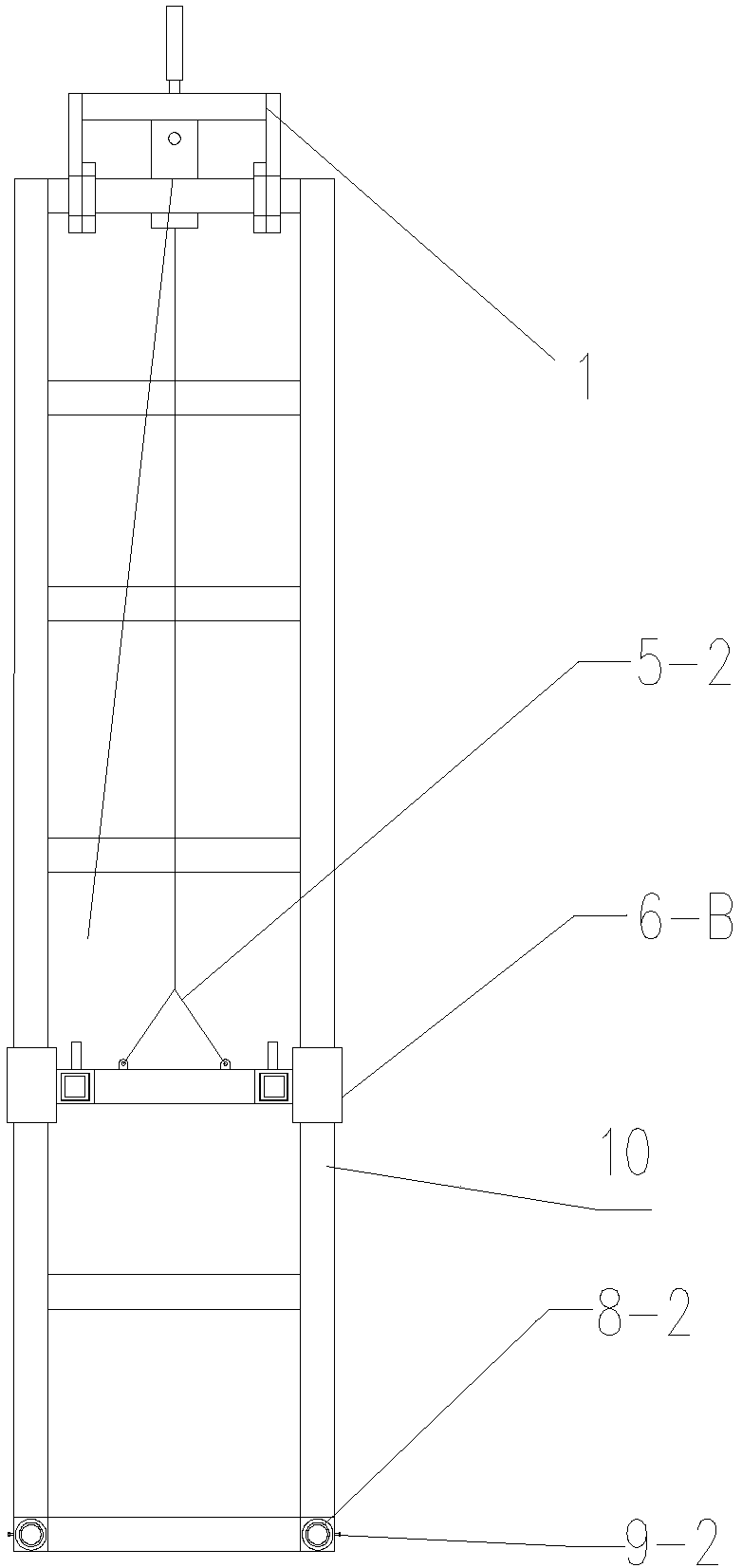

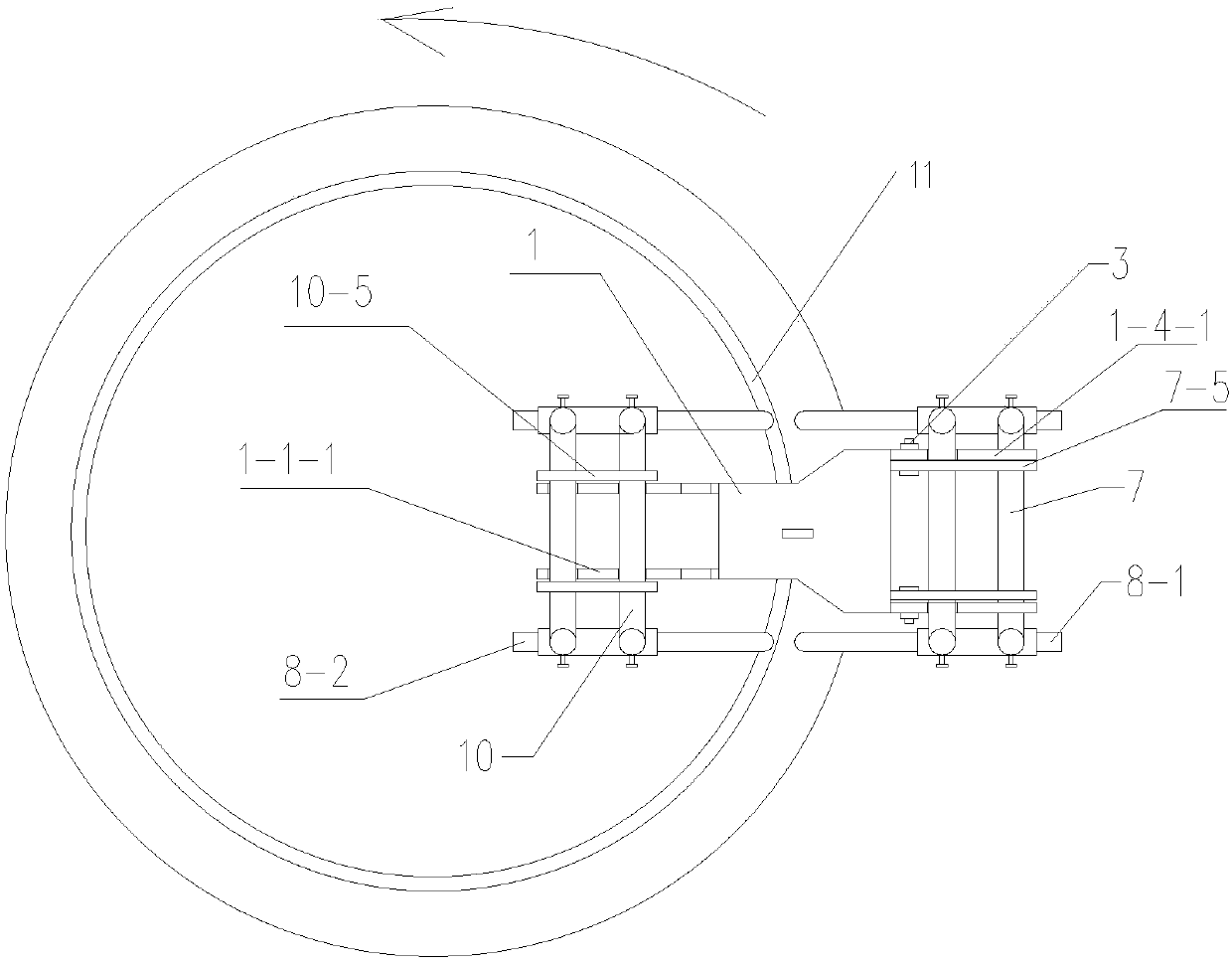

[0101] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes at least one operating device for welding and flaw detection verification of the longitudinal seam of the penstock 11. The operating device includes a suspension support mechanism 1, an external part installed on one side of the suspension support mechanism 1 and located outside the penstock 11. The operating platform 7 and the inner operating platform 10 installed on the other side of the suspension support mechanism 1 and inside the pressure steel pipe 11 are arranged between the inner operating platform 10 and the upper end of the outer operating platform 7 and can rotate along the top surface of the pressure steel pipe 11. Roller mechanism 2, the bottom of the suspension support mechanism 1 is provided with a roller positioning mechanism 4 for the installation of the roller mechanism 2, the internal operation platform 10 and the external operation platform 7 are vertically arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com