Inner container of drawer dishwasher and forming process of inner container

A technology for a dishwasher liner and molding process, which is applied to the washing machine/washing machine for tableware, the washing machine/rinsing machine parts for tableware, cleaning equipment, etc. The problem of high height can achieve the effect of reducing waste, reducing the cost of liner molding, and speeding up the molding rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

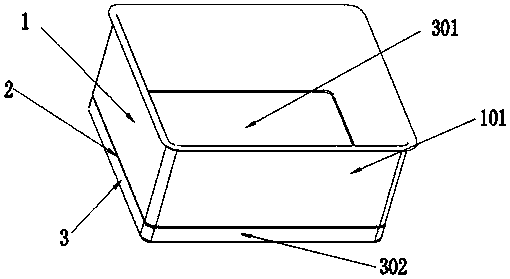

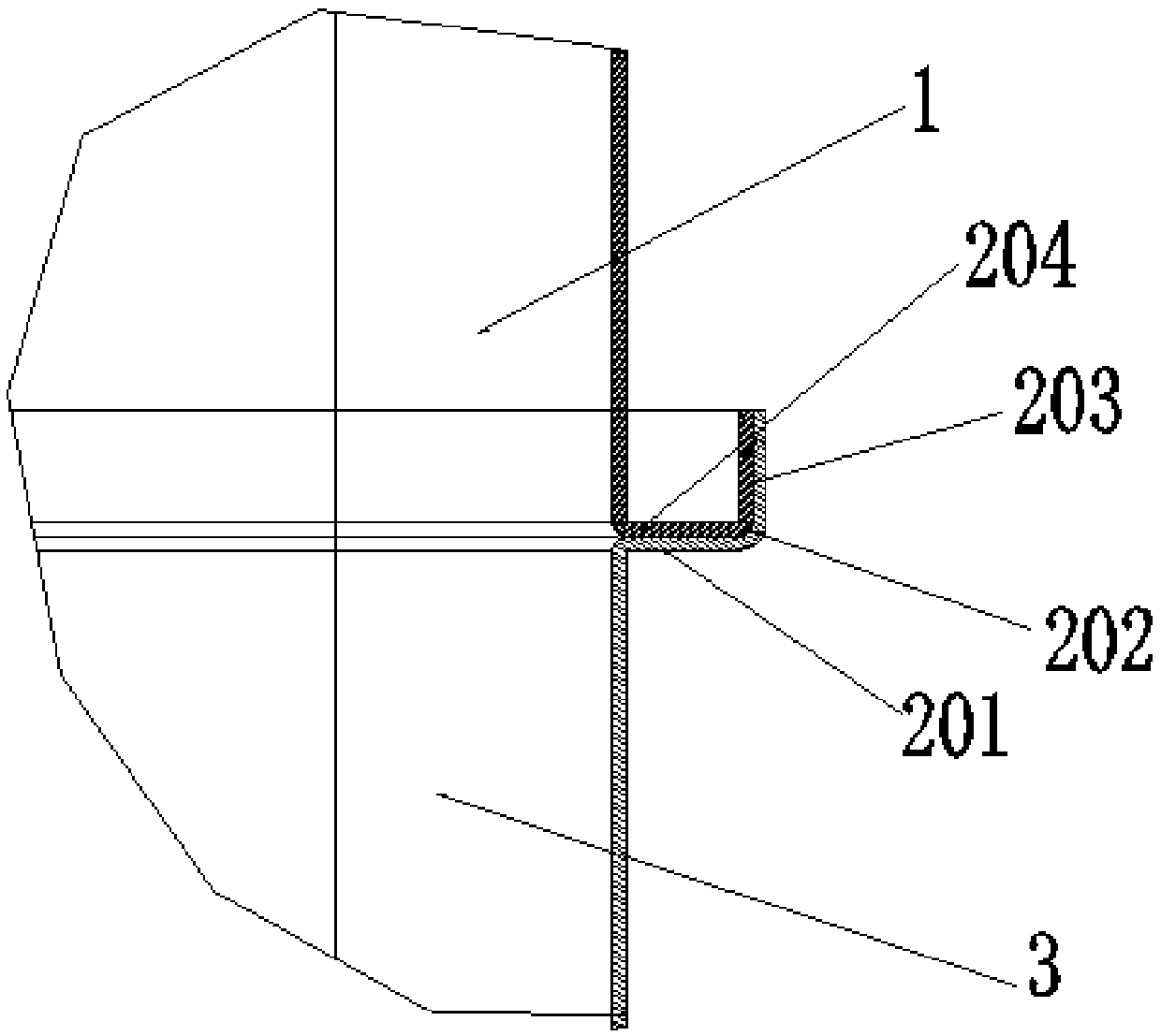

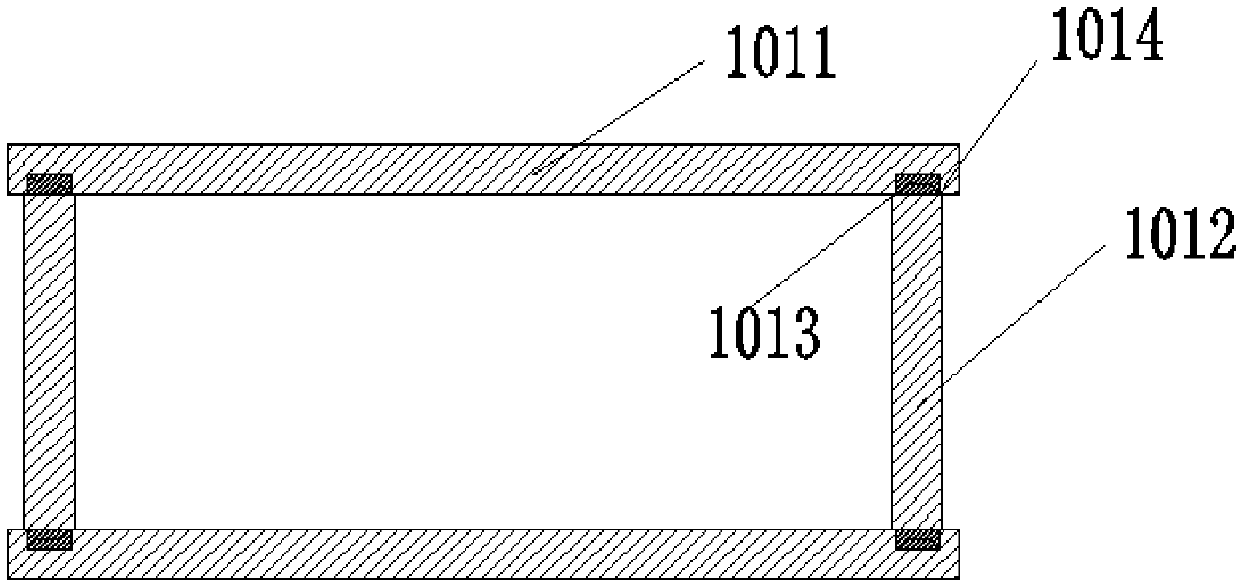

[0030] A liner for a drawer dishwasher. The liner includes an upper body 1 of the liner and a lower body 3 of the liner. The upper body 1 of the liner is provided with a placement groove for placing bowls and chopsticks. The placement groove extends from the upper body 1 of the liner to the The lower body of the liner 3; the present invention changes the structure of the traditional dishwasher liner. The traditional dishwasher liner generally uses one-time molding. The present invention adopts an assembled structure. The Chinese liner of the present invention includes the liner upper body 1 and The lower body 3 of the inner pot has a through groove on the upper body 1 of the inner pot, and there is a sinker groove on the lower body 3 of the inner pot. As a result, the stretching height is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com