Drilling riser joint and riser body automatic butting device

An automatic docking and riser technology, applied in drilling pipes, casings, manufacturing tools, etc., can solve the problems of unstoppable drilling, time-consuming, labor-intensive, capital-intensive, unsafe and other problems. The effect of improving production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

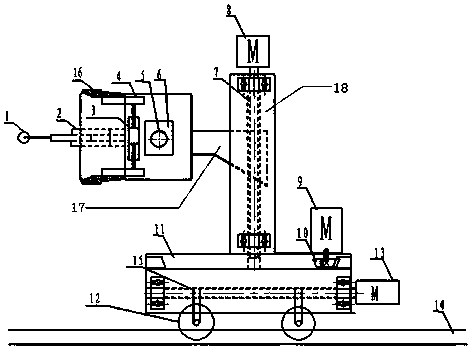

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] The automatic docking device between the riser joint and the pipe body includes a support detection part, a fixed part and a walking part. The detection part includes a detection head 1, a telescopic rod 2, a hydraulic cylinder 3, a clamping claw 4, a left and right walking screw 5 and an asynchronous servo The motor A6, the jaws 4 are fixed on both ends of the piston of the hydraulic cylinder 3, the telescopic rod 2 is fixedly connected with the left and right walking screws 5, the detection head 1 is fixed on the top of the telescopic rod, and the left and right walking screws 5 are connected with the asynchronous servo motor A6; fixed; The part includes a horizontal bracket 17, a vertical bracket 18, an up and down walking screw 7 and an asynchronous servo motor B8. The support detection part is connected with the up and down walking screw 7 through the horizo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter range | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com