PC alloy material, and preparation method and application thereof

A technology of alloy materials and uniform mixing, which is applied in the field of PC alloy materials and its preparation, can solve problems such as shortage, fluidity, warpage performance, internal stress performance, mold release performance, and color that cannot achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] In the examples and comparative examples, the method for preparing the PC alloy material includes the following steps:

[0105] 1) Weigh each component according to the content of the formula, and combine the polycarbonate, polyethylene terephthalate-1,4-cyclohexanedimethanol, fibrous fillers, and other additives that need to be pre-baked Carry out the pre-drying treatment at 120℃~130℃, and the pre-drying time is set to 4h~6h to obtain pre-baked polycarbonate and polyethylene terephthalate-1,4-cyclohexanedimethanol Ester, fibrous filler, other additives;

[0106] 2) The pre-baked polycarbonate, polyethylene terephthalate-1,4-cyclohexanedimethanol, fibrous fillers, and other additives are mixed uniformly through a high-speed mixer. The mixing temperature is 30℃~50℃, the mixing time is set at 5min~15min;

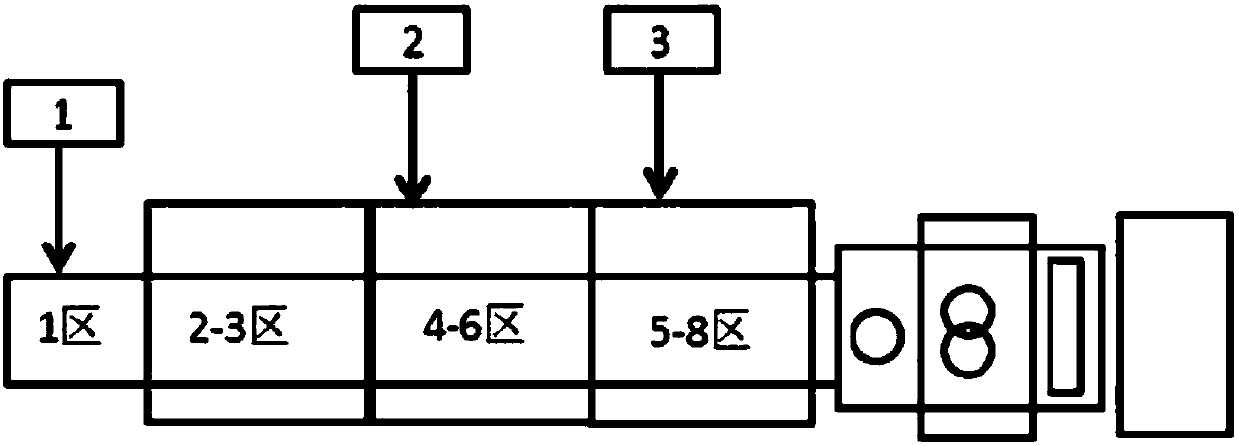

[0107] 3) Mix homogeneously polycarbonate, polyethylene terephthalate-1,4-cyclohexanedimethanol, other additives, aluminum salt or aluminum oxide, zirconium salt or zirconiu...

Embodiment 33

[0116] The method of adding glass fibers in Example 33: 3) is: based on the total weight of glass fibers, 40% of the total weight of glass fibers is added from the feed port 1 in the figure, and based on the total weight of glass fibers, 35% of the total weight of the glass fiber is added from the feed port 2. Based on the total weight of the glass fiber, 25% of the total weight of the glass fiber is added from the feed port 3. The glass fibers with a length of 100um to 300um in the obtained pellets account for 40% by weight of the glass fibers; and the glass fibers with a length greater than 300um but not more than 500um account for 25% by weight of the glass fibers.

Embodiment 34

[0117] The method of adding glass fiber in Example 34:3) is: based on the total weight of glass fiber, 20% of the total weight of glass fiber is added from feed port 1 in the figure, and based on the total weight of glass fiber, 35% of the total weight of the glass fiber is added from the feed port 2. Based on the total weight of the glass fiber, 45% of the total weight of the glass fiber is added from the feed port 3. The glass fibers with a length of 100um to 300um in the obtained pellets account for 60% of the weight of the glass fibers; the glass fibers with a length greater than 300um but not more than 500um account for 25% of the glass fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com