Modified polyethylene and preparation method thereof

A polyethylene and polyethylene-based technology, which is applied in the field of modified polyethylene, can solve the problems that the tensile strength and impact toughness of materials are difficult to meet at the same time, the melt flow rate is unstable, and the purity of polyethylene is high, so as to meet the requirements of hollow blowing. Plastic process and follow-up product performance requirements, wide range of equipment use, and wide range of performance adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Before describing the preparation method of the present invention, the present invention provides a description of the relevant structure of the twin-screw extrusion equipment designed in the present invention.

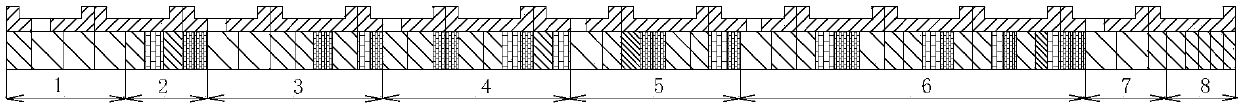

[0026] Such as figure 1 As shown, the twin-screw extruder is divided into 1-solid conveying section, 2-melting section A, 3-vacuum port A, 4-vacuum port B, 5-side feeding A, 6 from the feed port to the discharge port. - Side feeding B, 7- Melting section B, 8- Vacuum port C, 9- Homogenization and melt conveying section.

Embodiment 1

[0028] A modified polyethylene prepared from the following raw materials in weight percent:

[0029] 80% polyvinyl waste recycled materials, 0.25% 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, 0.6% bis-(4-methylbenzoyl) peroxide 0.05% 2,2-thiobis(4-tert-octylphenoxy)nickel, 0.12% 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, 7.5 % EPDM, 10% glass flakes, 0.5% tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, 0.28% 1,1, 3-Tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane, 0.7% of N,N'-ethylenebisstearamide.

[0030] The specific preparation method is as follows:

[0031] Mix polyethylene-based waste recycled materials, cross-linking agents and processing aids uniformly and then feed them into the twin-screw extruder from the main feeding port, mix the antioxidant and some reinforcement modifiers uniformly and then add them from side feeder A, and then The remaining reinforcement modifier and stabilizer are mixed evenly and then added from side feeder B,...

Embodiment 2

[0046] A modified polyethylene prepared from the following raw materials in weight percent:

[0047] 73% polyvinyl waste recycled materials, 0.7% dicumyl peroxide, 0.1% bis-(4-methylbenzoyl) peroxide, 0.15% tris(1,2,2,6 , 6-pentamethylpiperidinyl) phosphite, 0.15% resorcinol monobenzoate, 10% ethylene-vinyl acetate copolymer EVA, 15% attapulgite, 0.1% β-(3, 5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 0.5% dioctadecyl pentaerythritol diphosphite, 0.2% zinc stearate, 0.2% white mineral oil.

[0048] Concrete preparation method is identical with embodiment 1.

[0049] The control air pressure at vacuum port A is -0.055MPa, the control air pressure at vacuum port B is -0.076MPa, and the control air pressure at vacuum port A is -0.045MPa.

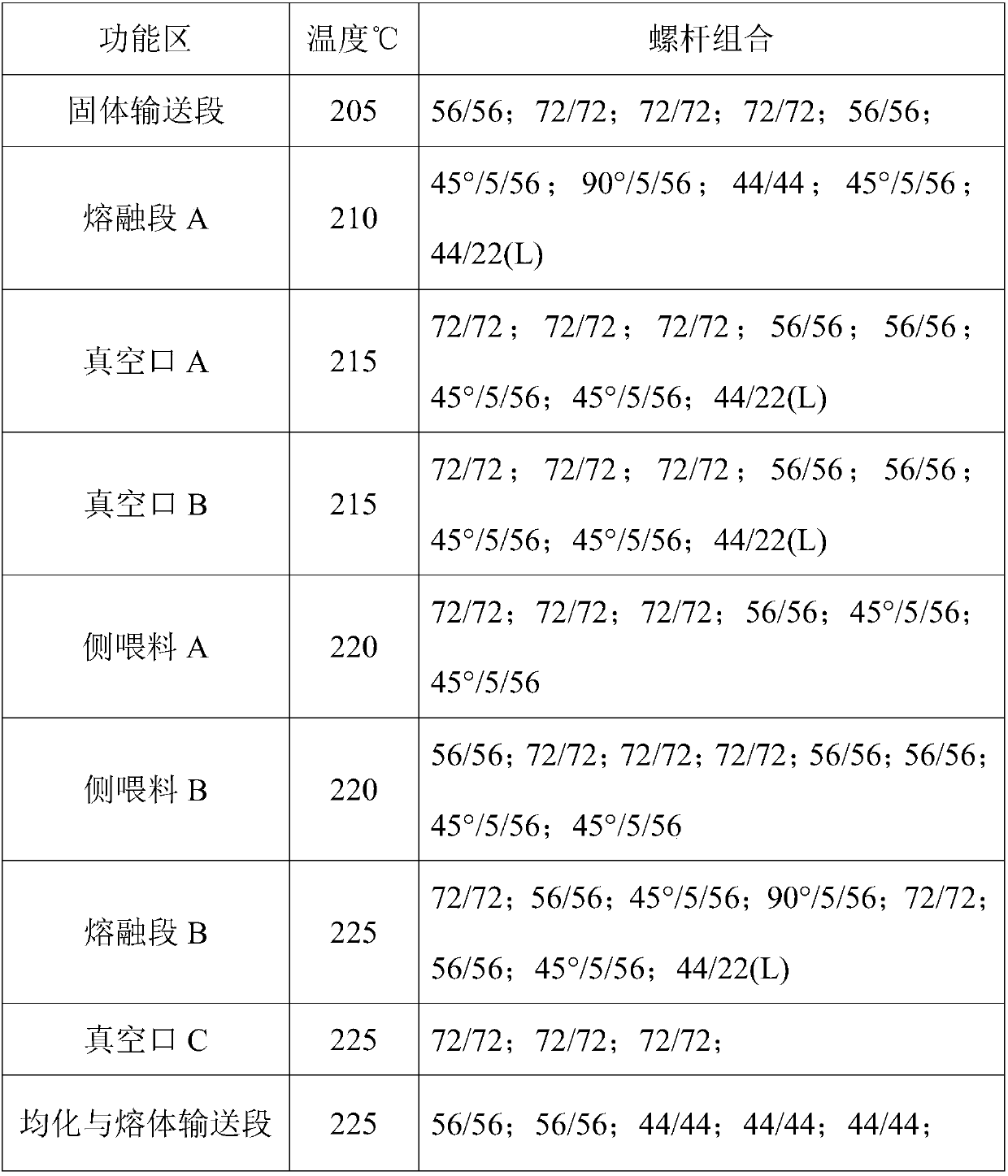

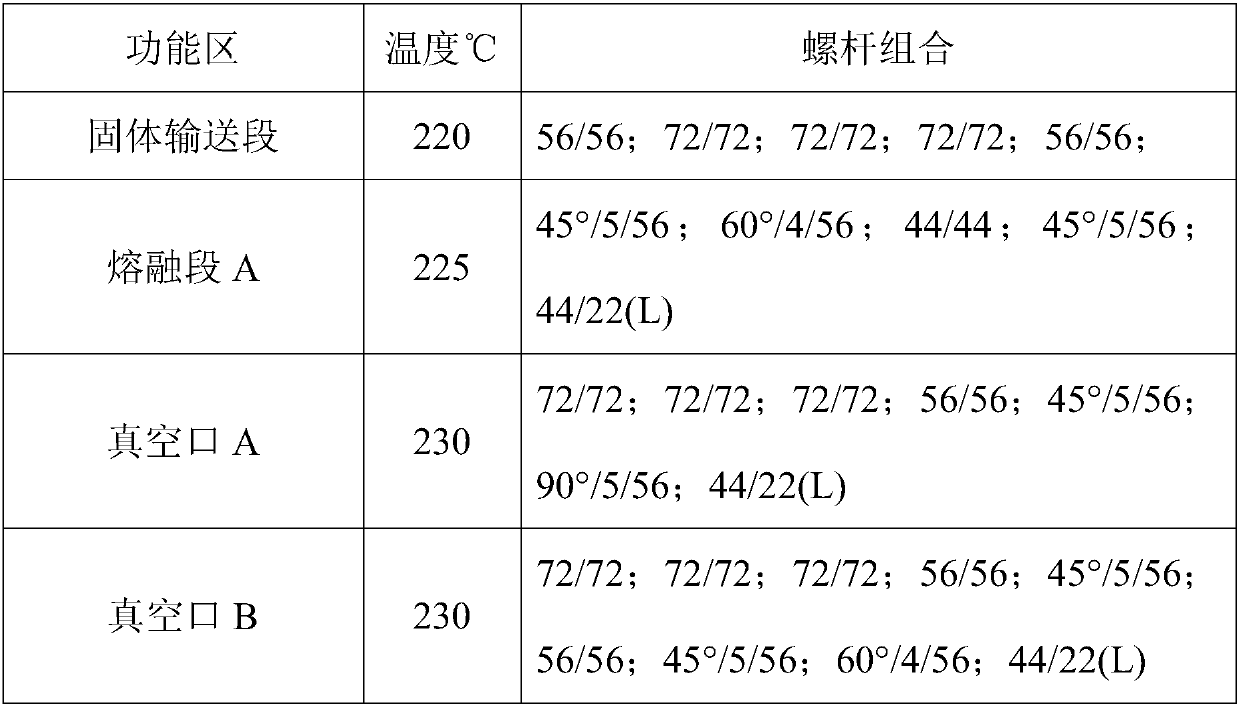

[0050] Extruder The speed of twin-screw extruder is 300r / min, and the temperature setting and screw combination of different functional areas during the reactive extrusion process are as follows:

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com