Direct blending and melting fertilizer forming device and method for producing biochar-based urea fertilizer

A biochar-based urea-based technology, applied in fertilization devices, fertilizer mixtures, urea compound fertilizers, etc., can solve problems such as low transportation efficiency, low strength of carbon-based slow-release nitrogen fertilizer, and destruction of the internal combination state of urea and biochar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

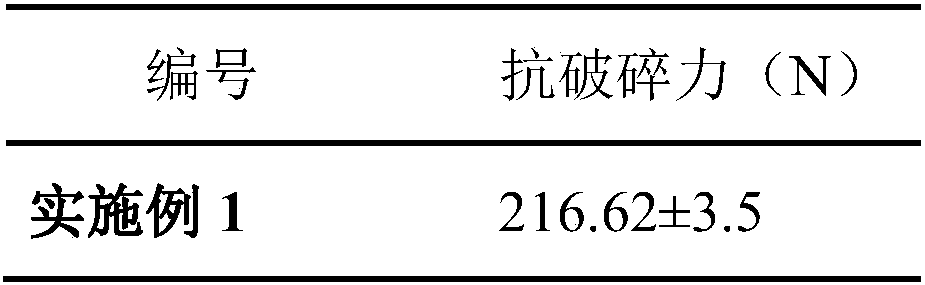

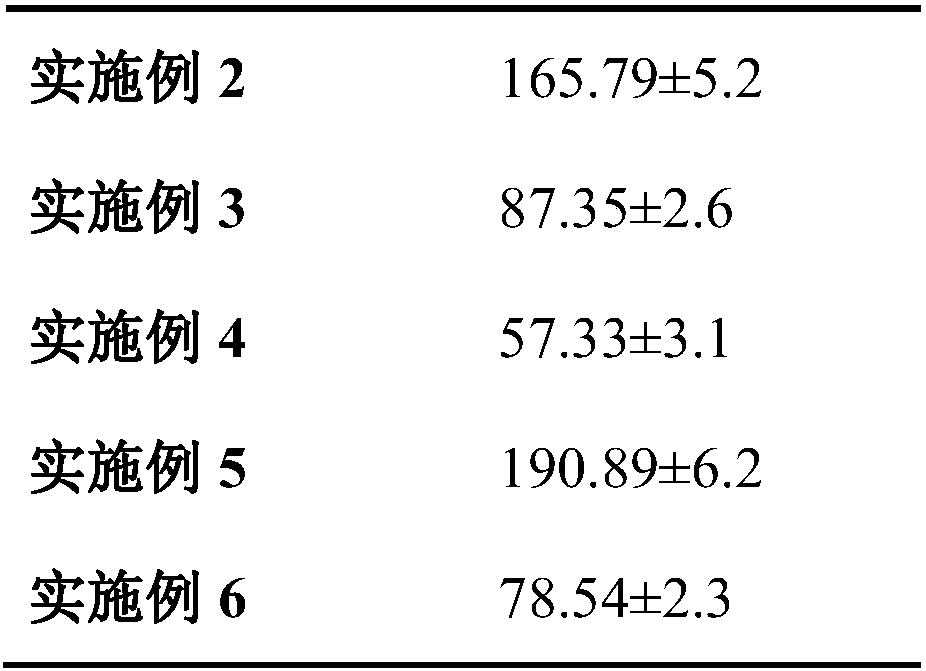

Examples

Embodiment 1

[0026] A biochar-based urea fertilizer direct-mixing melting fertilizer device, comprising a screw extruder 10, the screw extruder 10 is connected to a motor 6 and a transmission 7, and the extrusion rate is controlled by the motor 6 and the transmission 7, the screw extruder 10 is covered with a first heating chamber cover 5, the screw extruder 10 is provided with a material inlet and a material outlet, a mixer 4 is provided above the material inlet, and the mixer 4 is covered with a second heating chamber cover 2, A porous discharge mold 12 is provided at the discharge port, a biochar powder feed tank 1 and a urea solid powder feed tank 8 are arranged above the mixer 4 , and a rotary cutter 11 is provided on the outside of the porous discharge mold 12 . A connecting channel 9 is provided between the mixer 4 and the screw extruder 10, and a channel switch is provided at the connecting channel 9. It also includes a control device, which controls the operation of the motor 6 an...

Embodiment 2

[0036] The application of the device of the present invention in the preparation of biochar-based urea fertilizer:

[0037] 1) After biochar and urea are pulverized, pass through the biochar powder feed tank 1 and the urea solid powder feed tank 8 respectively and enter into the mixer 4 to fully stir evenly, wherein the mixer 4 is heated by the second heating chamber cover 2 and the temperature is controlled to 130 °C, the mass ratio of biochar to urea is 0.67:1;

[0038] 2) Turn on the channel switch of the channel 9 connecting the mixer 4 and the screw extruder 10, so that the mixed material enters the screw extruder 10, and the screw extruder 10 is heated by the first heating chamber sleeve 5 and the temperature is controlled at 155°C. To ensure that the urea maintains a stable molten state, the screw extruder 10 controls the extrusion speed through the transmission 7 and the motor 6, so that the biochar and the molten urea fully contact and extrude the porous discharge die...

Embodiment 3

[0041] The application of the device of the present invention in the preparation of biochar-based urea fertilizer:

[0042] 1) After biochar and urea are pulverized, pass through the biochar powder feed tank 1 and the urea solid powder feed tank 8 respectively and enter into the mixer 4 to fully stir evenly, wherein the mixer 4 is heated by the second heating chamber cover 2 and the temperature is controlled to 130 °C, the mass ratio of biochar to urea is 1.5:1;

[0043] 2) Turn on the channel switch of the channel 9 connecting the mixer 4 and the screw extruder 10, so that the mixed material enters the screw extruder 10, and the screw extruder 10 is heated by the first heating chamber sleeve 5 and the temperature is controlled at 155°C. To ensure that the urea maintains a stable molten state, the screw extruder 10 controls the extrusion speed through the transmission 7 and the motor 6, so that the biochar and the molten urea fully contact and extrude the porous discharge die ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com