Method for producing chlorate in different grain diameters by three-section continuous low-temperature vacuum evaporative crystallization

A low-temperature vacuum, evaporative crystallization technology, applied in the direction of evaporative separation crystallization, chlorate, chloric acid, etc., can solve the problems such as the inability to accurately obtain the predetermined chlorate solid, and avoid difficult washing, large particle size, and difficult formation. block effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

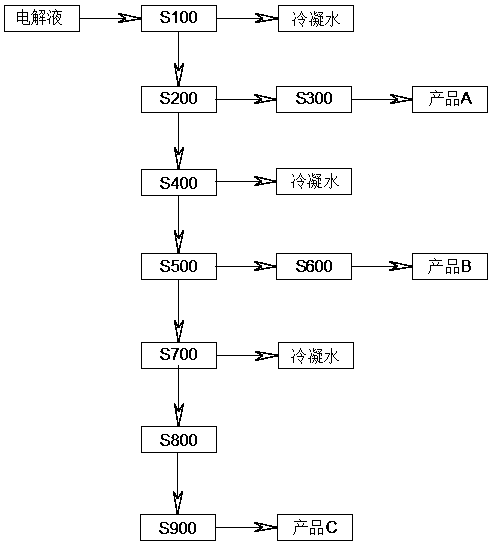

[0039] combined with figure 1 Shown, a kind of three-stage continuous low-temperature vacuum evaporation crystallization produces the method for chlorate of different particle sizes, adopts the following steps to make:

[0040] In this embodiment, the following steps were adopted to prepare sodium chlorate-NaClO3 solids with different particle sizes. The following nine steps are specifically adopted. Of course, it is worth noting that the method recorded in this embodiment is applicable to the preparation of all chlorates, and can receive substantially the same technical effect. The error of the diameter is negligible for industrial applications. The following is specifically described with sodium chlorate:

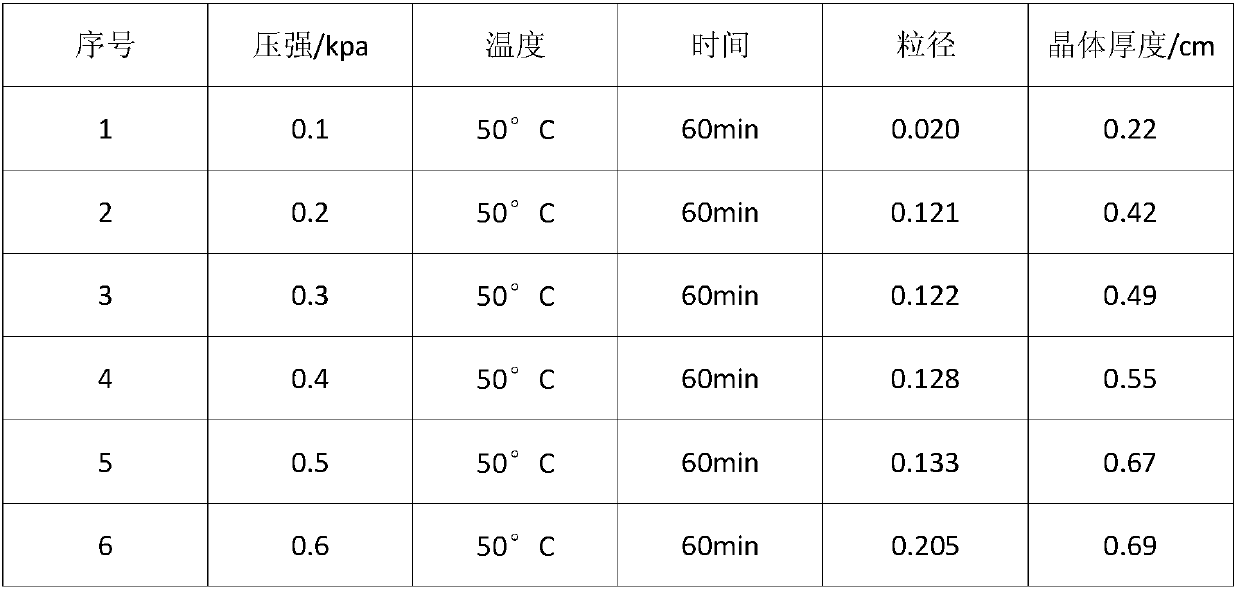

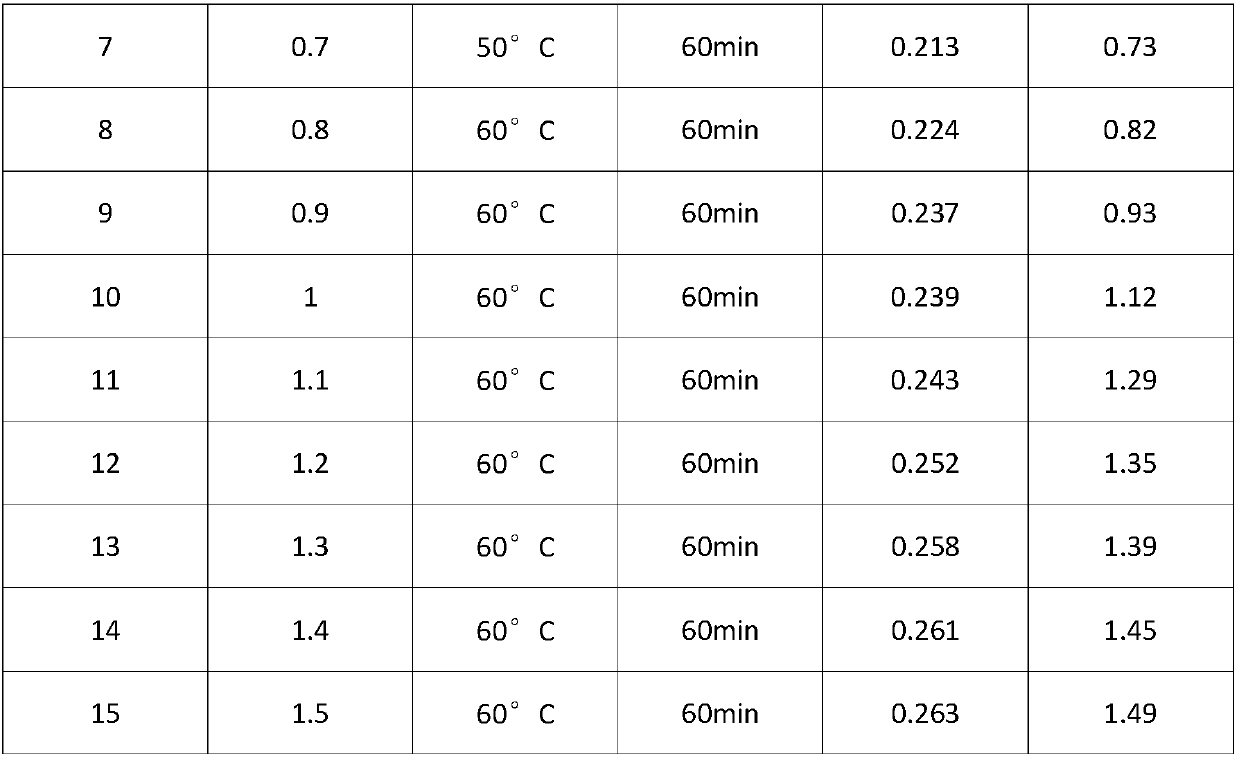

[0041]Step S100: Low-temperature vacuum evaporation continuous crystallization A, the sodium chlorate electrolyte solution with a concentration of 480g / L-620g / L is continuously crystallized at a temperature of 0.81KPa to 0.86KPa and a temperature of 48-52°C to obtain th...

Embodiment 2

[0072] In order to avoid a small part of sodium chlorate whose particle size is too large or too small to be mixed therein, on the basis of Example 1, further in combination with the attached figure 1 The step, in the present embodiment, in described step S300, sodium chlorate solid is carried out between drying and packing and also includes the step that the sodium chlorate solid after drying is filtered, specifically comprises:

[0073] Step S301, putting the dried sodium chlorate solid into a filter shaker for filtration and screening to obtain sodium chlorate with a particle size greater than 0.2 mm and less than 0.3 mm; meanwhile, obtain sodium chlorate with a particle size less than 0.2 mm and greater than 0.3 mm Sodium chlorate; The vibrating sieve mesh in the described filtration shaker is two layers, and the aperture of the upper strata is 0.3 millimeter, and the aperture of the lower floor is 0.2 millimeter;

[0074] Step S302, sending sodium chlorate with a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com