LED bracket with overflow channel and overflow slot and manufacturing method thereof

A technology of LED bracket and overflow channel, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of unevenness of devices, poor thermal conductivity, etc., to improve thermal conductivity, increase pad area, and improve device process consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

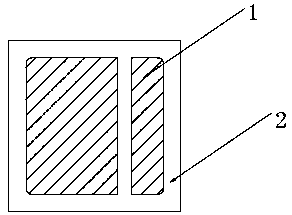

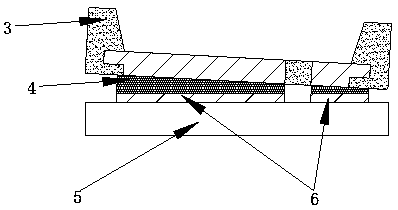

[0029] see Figure 5-Figure 7 , the present invention provides an LED bracket with an overflow channel and an overflow groove, including a substrate 2, preferably, the substrate 2 is made of a copper substrate 201 molded and injected with a thermosetting resin material 202, such as EMC (Epoxy Molding Compound ), SMC (Sheet Molding Compound) and other materials. The front side of the substrate 2 is used to place LED chips. The LED chips can adopt a front-mount chip structure, a vertical chip structure or a flip-chip structure. The front area of the substrate 2 is adaptively adjusted according to different chip structures. A pad 1 is provided on the back of the substrate 2, and the pad 1 is used for connecting an external circuit. Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com