Preparation method of flexible touch substrate and flexible touch substrate

A flexible touch and substrate technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc. rate and efficiency, the effect of increasing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

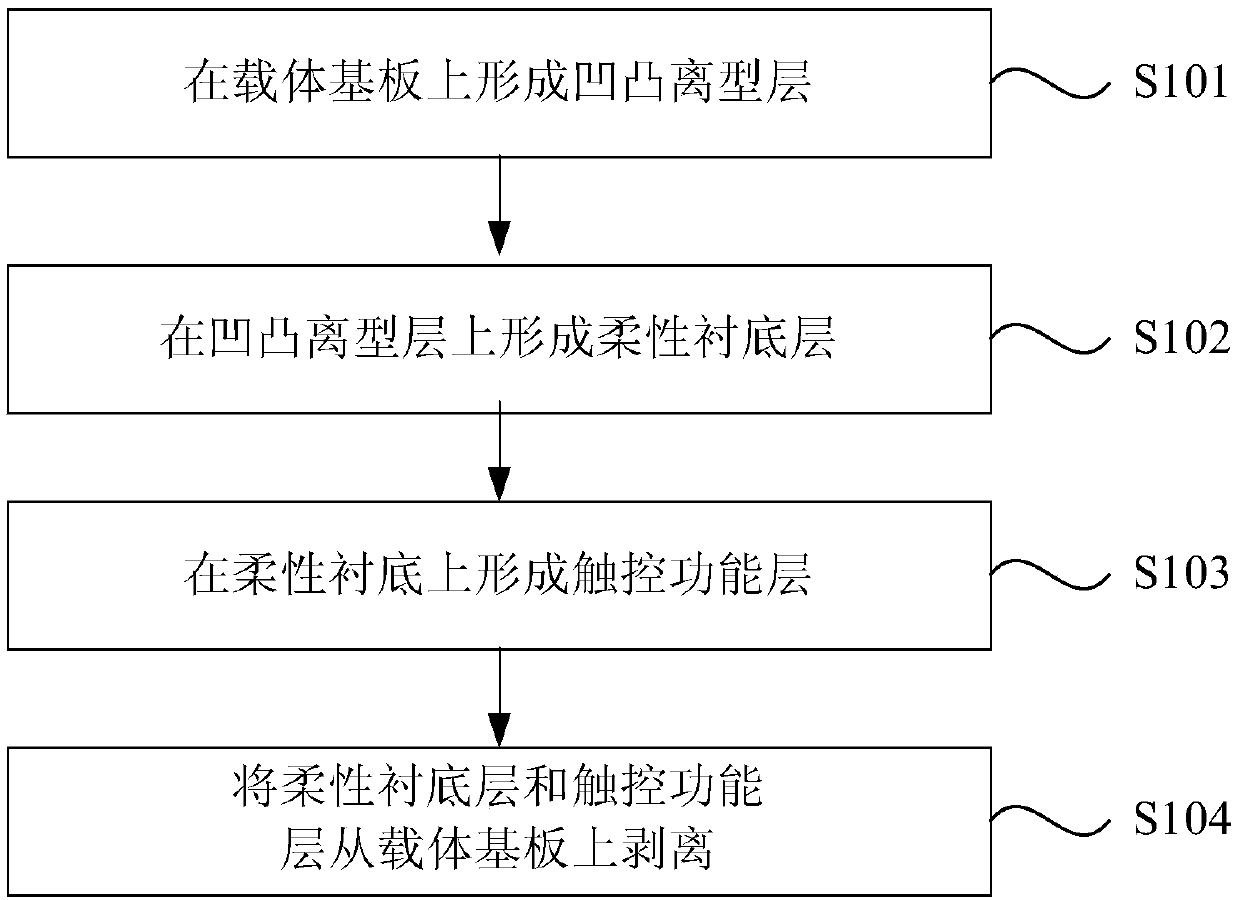

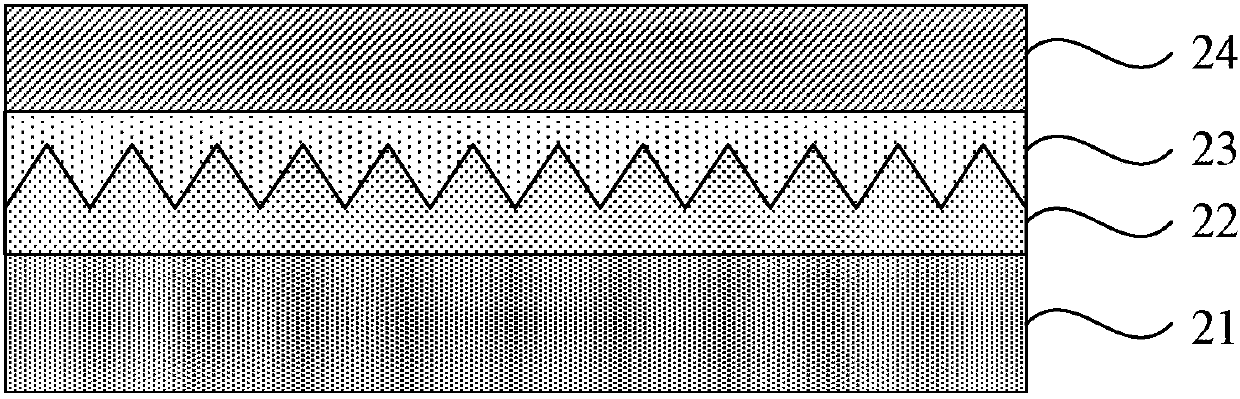

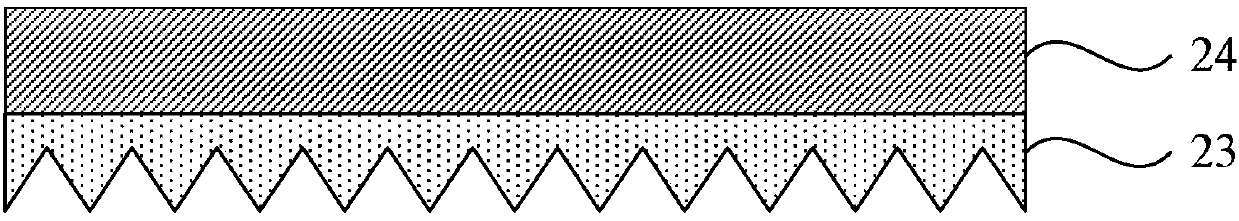

[0043] figure 1 It is a flow chart of a method for preparing a flexible touch substrate provided in Embodiment 1 of the present invention, figure 2 It is a schematic cross-sectional view of the flexible touch substrate to be peeled off provided by Embodiment 1 of the present invention, image 3 It is a schematic cross-sectional view of the stripped flexible touch substrate provided by Embodiment 1 of the present invention. Wherein, the structure of the flexible touch substrate is a carrier substrate 21, a concave-convex release layer 22, a flexible substrate layer 23, and a touch function layer 24 in sequence. The preparation method of the flexible touch substrate specifically includes the following steps:

[0044] Step 110, forming a concave-convex release layer on the carrier substrate;

[0045] Wherein, the flexible touch screen needs to use a rigid carrier substrate 21 as a carrier during the manufacturing process, and the material of the carrier substrate 21 can be gla...

Embodiment 2

[0058] Figure 4 It is a flow chart of another method for preparing a flexible touch substrate provided in Embodiment 2 of the present invention, Figure 5 It is a schematic diagram of the V-groove carrier substrate provided in Embodiment 2 of the present invention, refer to Figure 4 , Figure 5 , wherein, S101, forming a concave-convex release layer on the carrier substrate may be S201, performing a concave-convex treatment on the carrier substrate, so that a concave-convex release layer is formed on one surface of the carrier substrate.

[0059] Among them, refer to Figure 5 The carrier substrate 21 itself can be subjected to a concave-convex treatment. The upper surface of the carrier substrate 21 forms a microscopic concave-convex structure through the concave-convex treatment. After the concave-convex treatment, the upper surface of the carrier substrate 21 forms a V-shaped groove-shaped concave-convex structure.

[0060] The technical solution of the embodiment of t...

Embodiment 3

[0066] Figure 8 It is a flow chart of another method for preparing a flexible touch substrate provided in Embodiment 3 of the present invention, Figure 9 It is a schematic diagram of a V-shaped groove-shaped concave-convex release layer provided in Embodiment 3 of the present invention, wherein, S101, forming a concave-convex release layer on a carrier substrate may be S301, coating a low-release force material on a carrier substrate to form a release film , Carry out concave-convex treatment on the release film to form a concave-convex release layer.

[0067] Among them, the low release force means that the surface adhesion is low, and it is easier to peel off later, and coating the low release force material on the carrier substrate 21 can ensure that the flexible substrate layer on it is easier to peel off, and the surface is processed by embossing. As for the release film, the concave-convex release layer 22 shown in reference 8 is formed. Optionally, the low release f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com