Multifunctional friction-wear test device and method for simulating space environment

A friction and wear test, space environment technology, used in measuring devices, testing wear resistance, using repetitive force/pulse force to test material strength, etc., can solve problems such as insufficient reflection of material friction and wear conditions and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

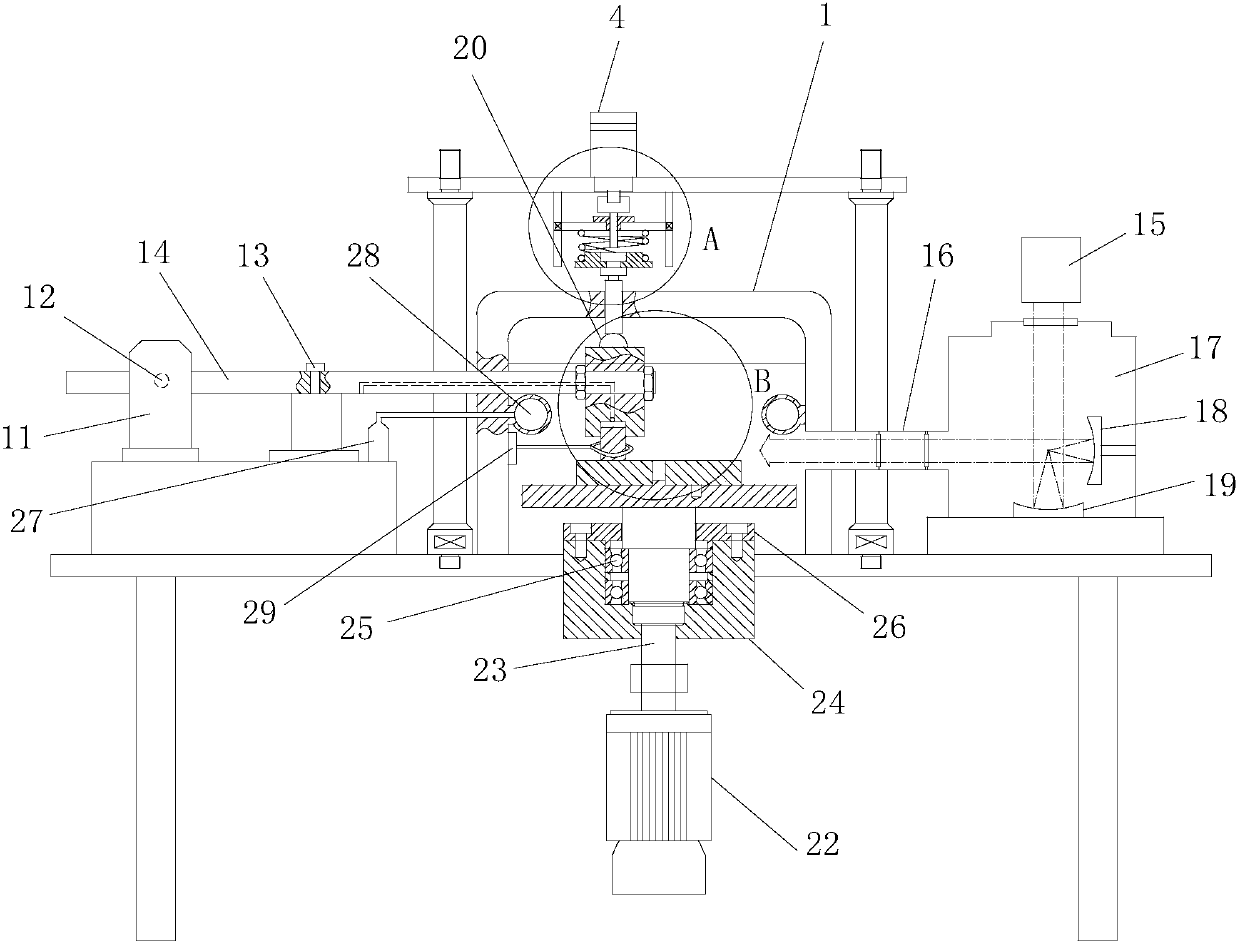

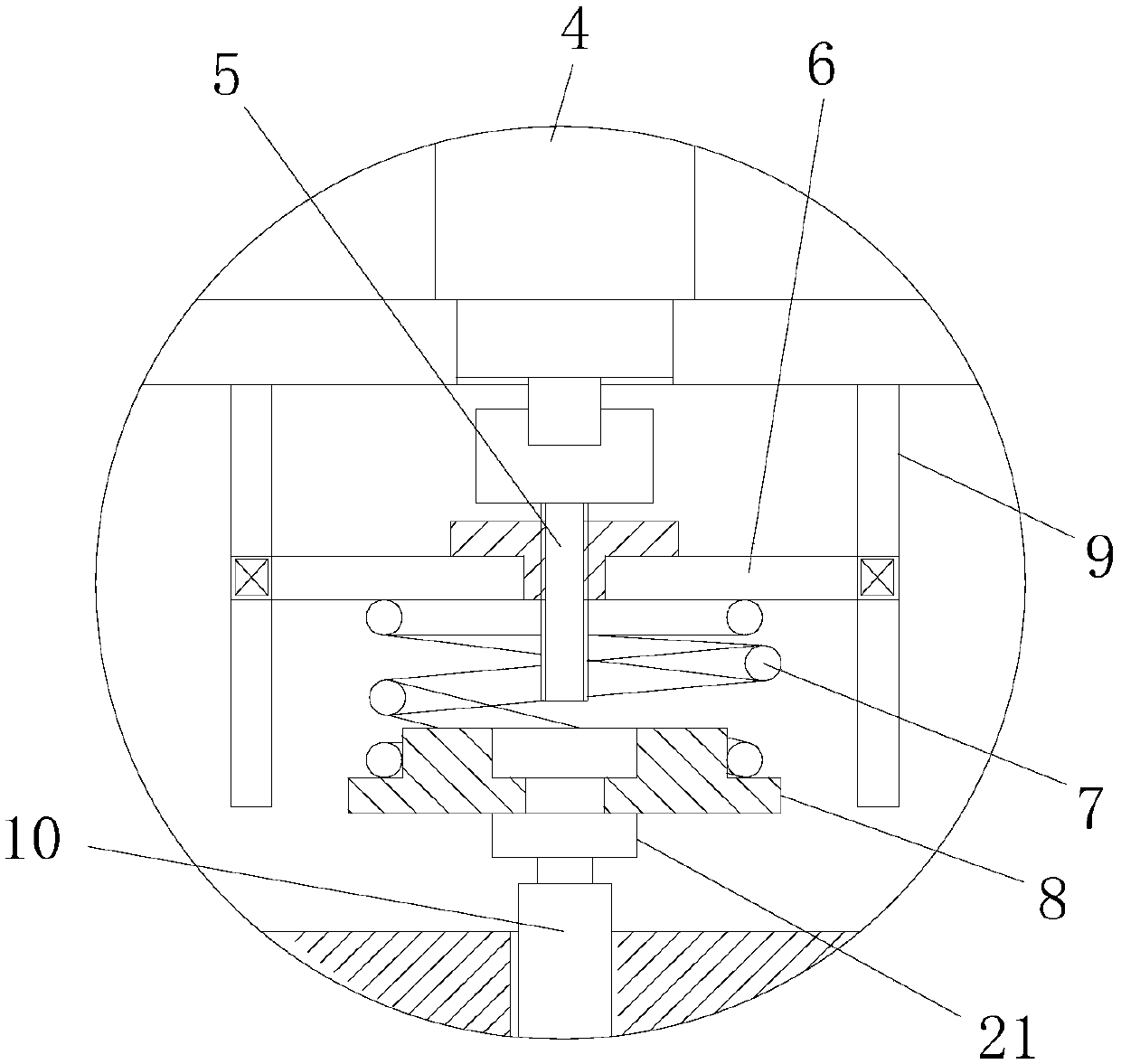

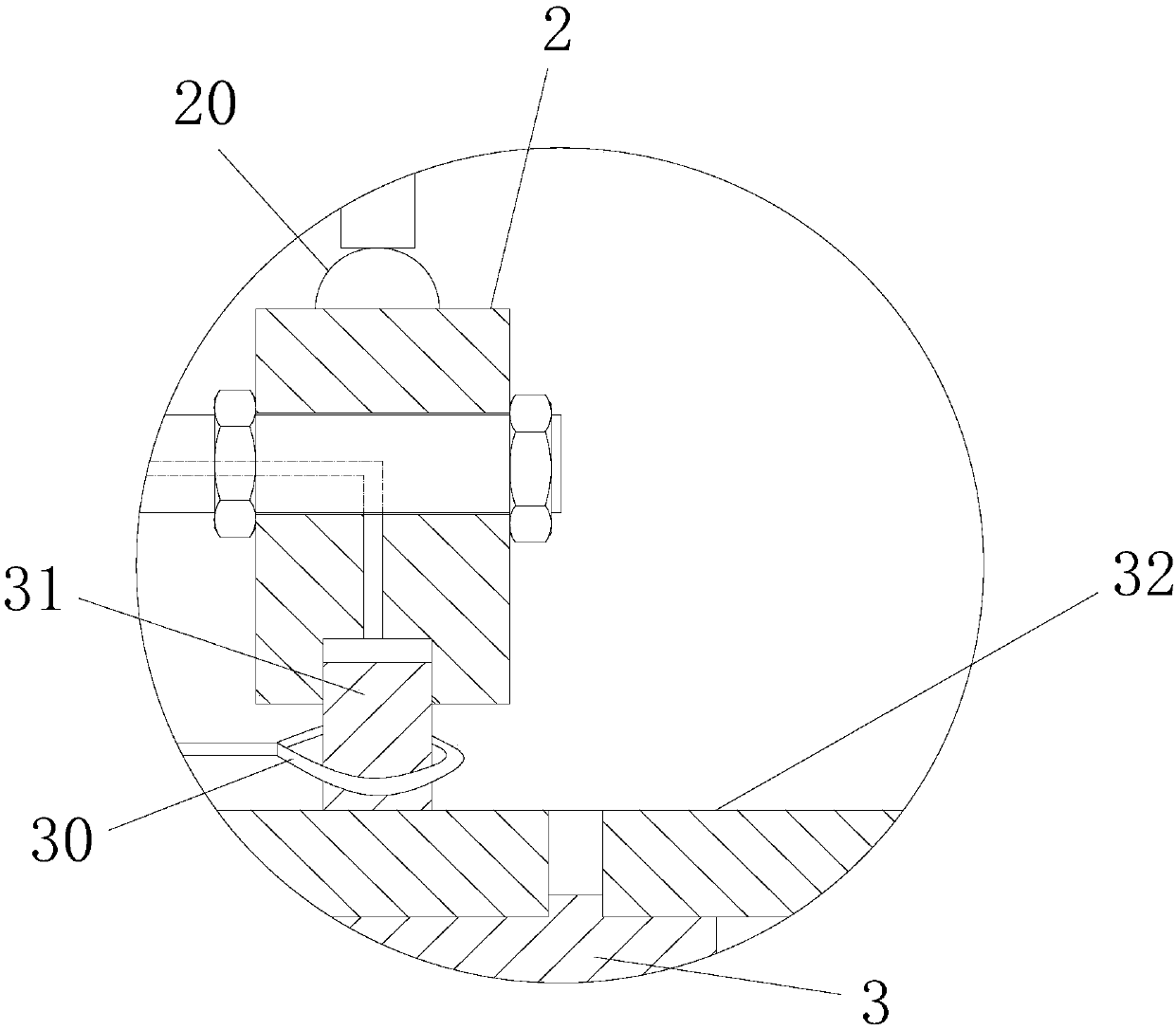

[0038]A multifunctional friction and wear test device for simulating a space environment, including a load loading mechanism, a vacuum box, a friction detection mechanism, an upper sample fixture, a lower sample mounting seat, an ultraviolet generating device for irradiating ultraviolet rays to the sample, and a device for making the vacuum Refrigeration system for temperature drop in the chamber, heating system for raising the temperature in the vacuum chamber, and lower sample drive system for driving the lower sample mounting seat to drive the lower sample to rotate relative to the upper sample;

[0039] The load loading mechanism includes a stepping motor, a ball screw, a spring push plate, a loading spring, a spring mounting seat, a guide rail and a loading force transmission shaft, the power output shaft of the stepping motor is connected with the ball screw, and the connection between the spring push plate and the ball screw Sliding nut connection, the guide rail is set ...

Embodiment 2

[0055] A kind of simulated space environment friction and wear test method that uses the simulated space environment multifunctional friction and wear test device described in embodiment one to carry out, comprises the following steps:

[0056] Sample installation: install the upper sample and the lower sample on the upper sample fixture and the lower sample mounting seat respectively, vacuumize the vacuum box, and set the friction environment after reaching the required vacuum value;

[0057] Friction environment setting includes loading force setting, friction environment temperature setting, irradiation condition setting and friction state setting;

[0058] Loading force setting: start the stepping motor to drive the ball screw to rotate, the spring push plate slides down along the guide rail under the push of the ball screw nut to compress the loading spring, and the loading spring presses down on the spring mounting seat after the force is applied, and the spring is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com