Nozzle devices and road cleaning equipment

A pulverizing device and straw technology, which are used in road cleaning, cleaning methods, construction, etc., can solve the problems of poor suction and pick-up ability and poor pulverizing effect, and achieve the effect of improving suction and picking ability, improving airtightness and good pulverizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

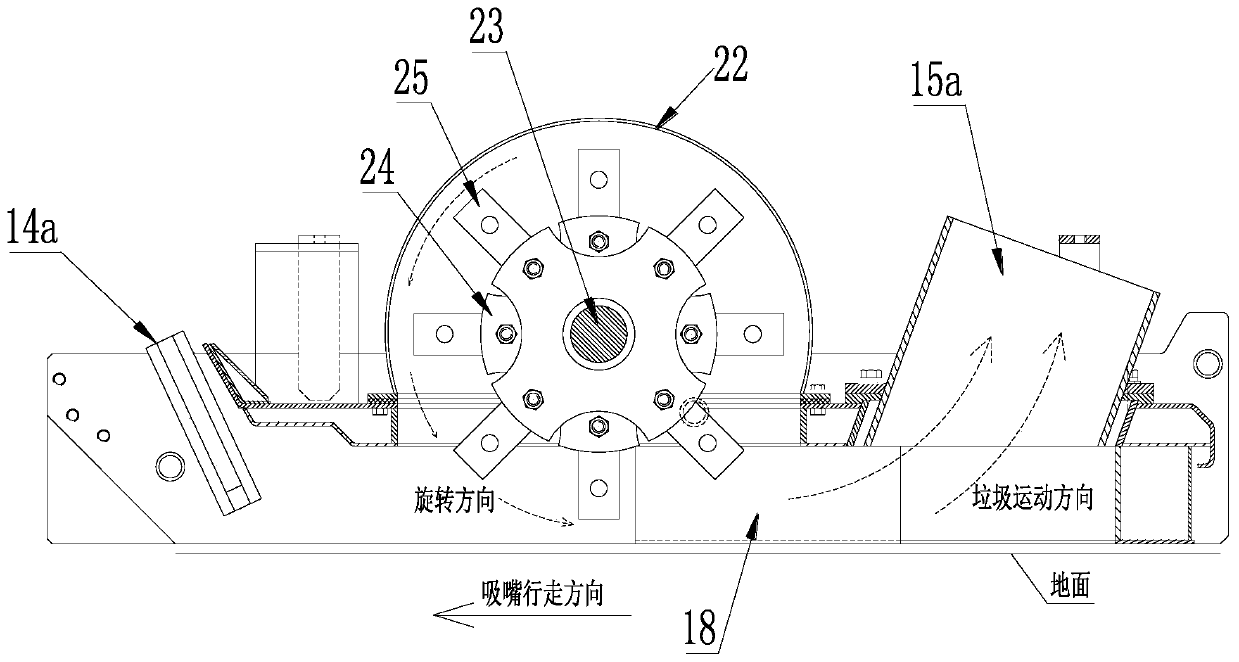

[0036] The core idea of the present invention is to improve the suction effect of the suction nozzle device in the road cleaning device, and on this premise, the suction nozzle device can meet the suction and pickup requirements of various garbage. For this reason, a front baffle is arranged in front of the suction nozzle chamber to improve the airtightness of the suction nozzle chamber relative to the ground, thereby improving the suction effect. The front baffle is set a certain distance from the ground to allow room for debris to enter the nozzle chamber. It should be noted that the front here refers to the traveling direction of the road cleaning device, that is to say, the position where the garbage enters the nozzle chamber.

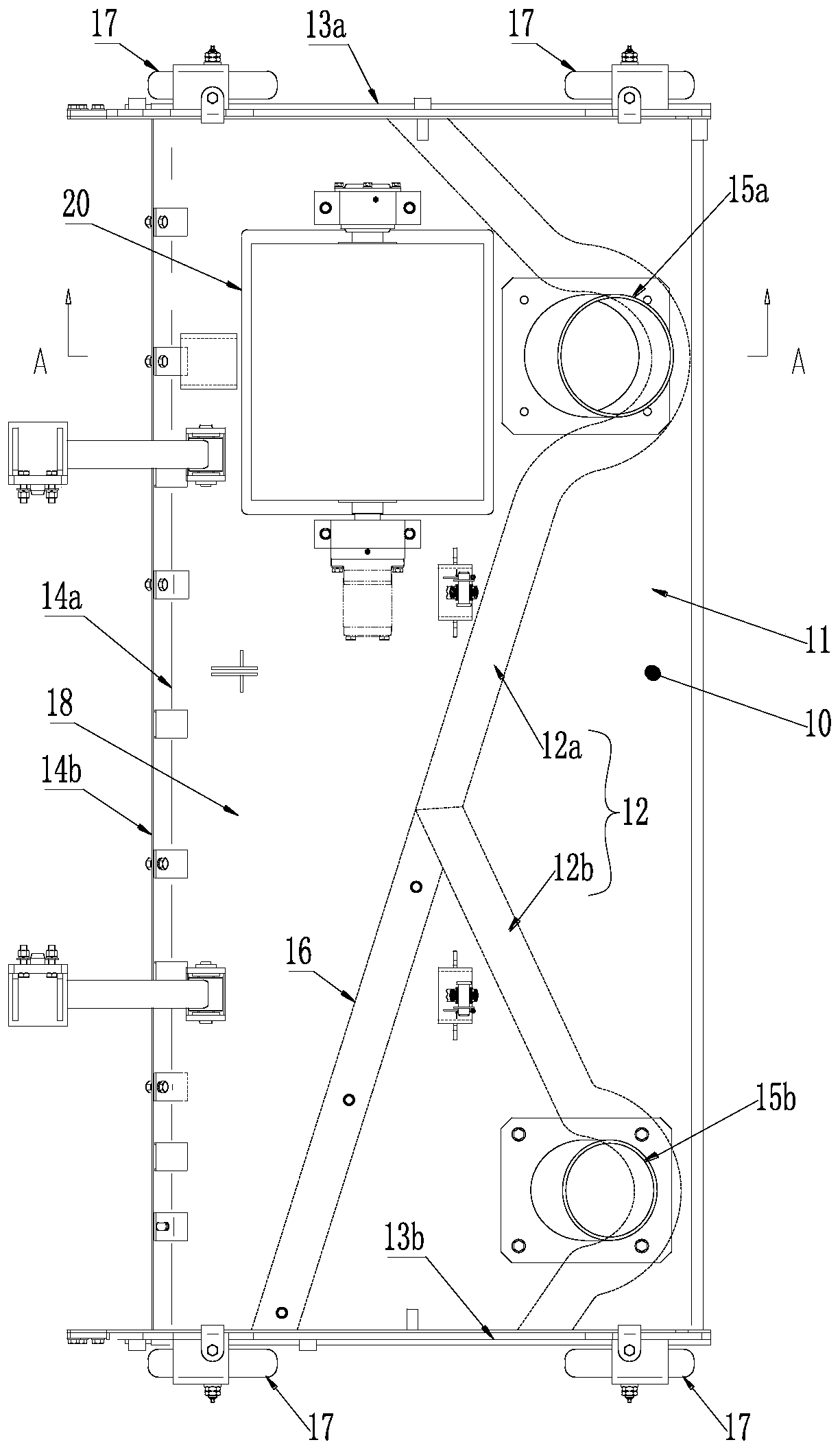

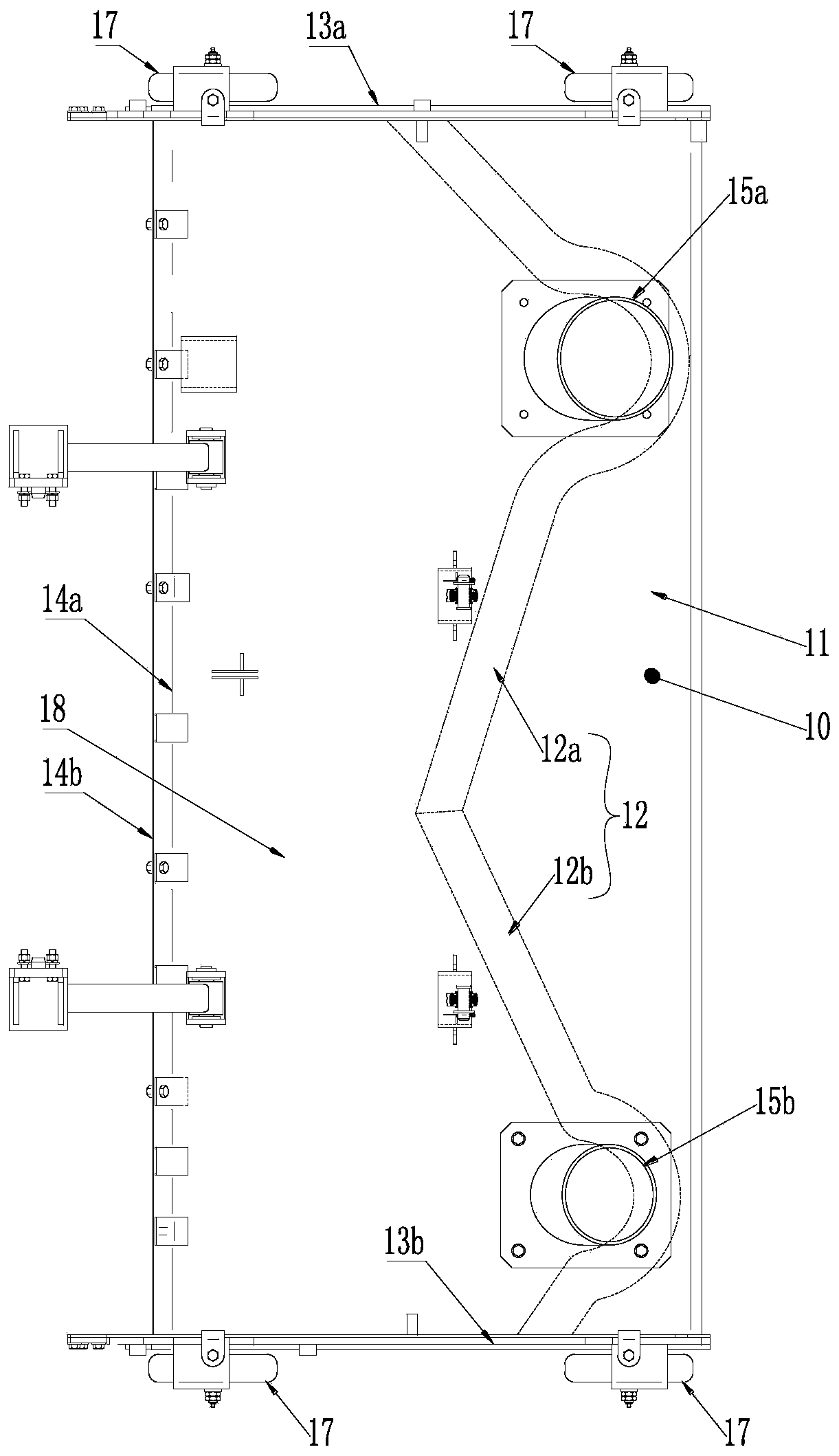

[0037] participate Figure 1-Figure 4 , this embodiment provides a suction nozzle device, which specifically includes: a suction nozzle body 10 and a crushing device 20 arranged on the suction nozzle body 10; the crushing device 20 can be instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com