Ice melting agent for electric transmission line and preparation method thereof

A technology of transmission lines and deicing agents, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effect of preventing secondary icing, excellent deicing and snow melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

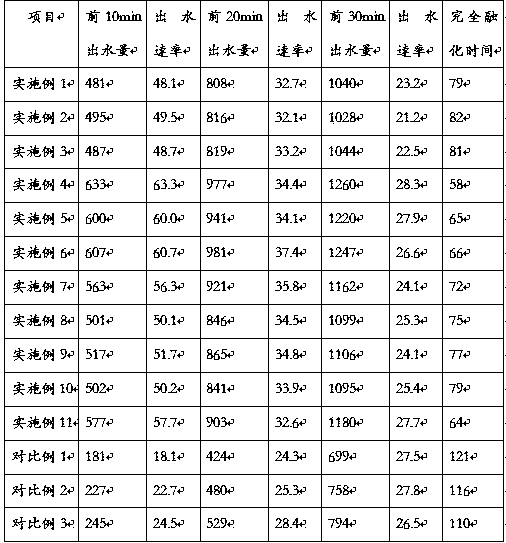

Examples

preparation example Construction

[0025] The preparation method of the deicing agent for power transmission lines of the present invention comprises the following steps:

[0026] Step 1, add sodium chloride, ammonium chloride and potassium oxide to soda ash and stir and mix evenly to obtain powdery mixture A;

[0027] Step 2. After mixing trichloroacetic acid and other components, heat and dry at 80°C for 20-30 minutes, and then crush it into powder to obtain mixture B;

[0028] Step 3. Stir and mix mixture A and mixture B evenly under dry conditions to obtain the ice-melting agent.

Embodiment 1

[0031] Get 58 grams of sodium chloride powder and 23 grams of soda ash, 4 grams of ammonium chloride and 3 grams of potassium oxide and mix evenly to obtain powdery mixture A, then mix 11 grams of trichloroacetic acid and 1 gram of sodium benzoate at 80 ° C Heating and drying at low temperature for 20 minutes, and then breaking into powder to obtain mixture B, and finally stirring and mixing mixture A and mixture B under dry conditions to obtain 100 g of ice-melting agent.

Embodiment 2

[0033] Get 53 grams of sodium chloride powder and 20 grams of soda ash, 7 grams of ammonium chloride and 6 grams of potassium oxide and mix evenly to obtain powdery mixture A, then mix 13 grams of trichloroacetic acid and 1 gram of sodium benzoate at 80 ° C Heating and drying at low temperature for 23 minutes, and then breaking into powder to obtain mixture B, and finally stirring and mixing mixture A and mixture B under dry conditions to obtain 100 grams of ice-melting agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com