Potassium superoxide piece and molding method thereof

A technology of potassium superoxide and molding method, applied in chemical instruments and methods, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve problems such as easy generation of a large amount of dust, inconvenience to use, loose tablets, etc., Achieve the effect of increasing user comfort, low dust rate, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

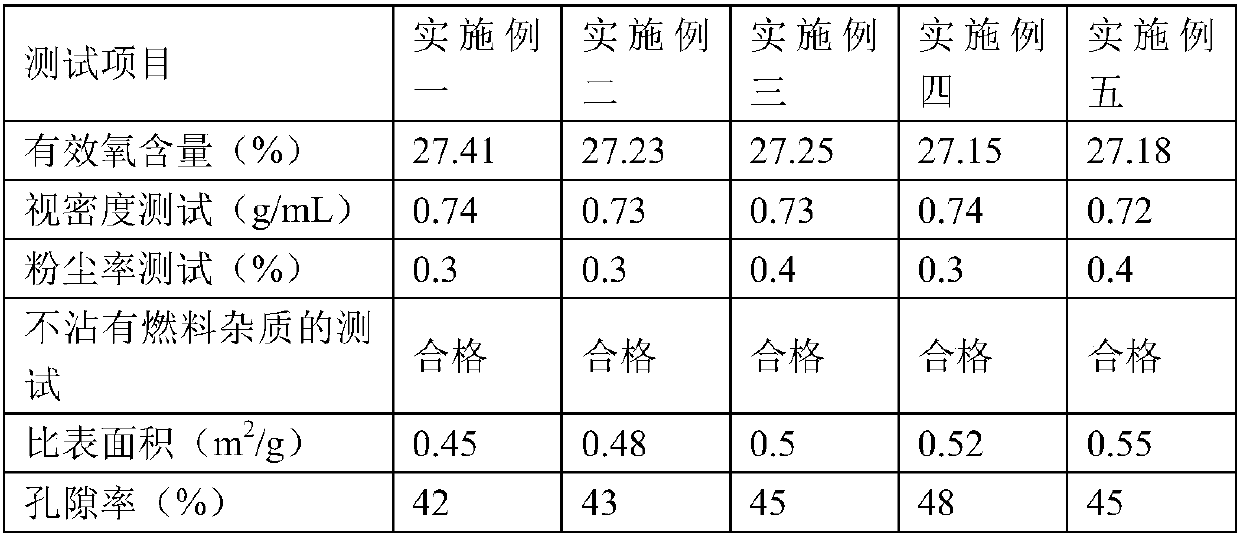

Examples

Embodiment 1

[0027] Embodiment 1: A method for forming potassium superoxide tablets, including the following steps:

[0028] Take 100g of potassium superoxide powder (particle size: 20 mesh) with 30% oxygen content, 14g potassium hydroxide (particle size: 60 mesh), and 1g copper oxychloride (particle size: 80 mesh), stir and mix to obtain a powder mixture ;

[0029] Put the powder mixture into a Φ6mm*2.5mm mold, and press the powder mixture under a pressure of 80MPa to form potassium superoxide tablets; the temperature of the system is maintained at 25°C and the humidity is 30% during the entire preparation process.

Embodiment 2

[0030] Embodiment 2: A method for forming potassium superoxide tablets, including the following steps:

[0031] Take 100g of potassium superoxide powder (particle size of 20 mesh) with 30% oxygen content, 14g of potassium hydroxide (particle size of 60 mesh), and 2g of copper oxychloride (particle size of 80 mesh), stir and mix uniformly to obtain a powder mixture ;

[0032] The powder mixture is put into a Φ8mm*2.7mm mold, and the powder mixture is pressed under a pressure of 80 MPa to form potassium superoxide tablets; the temperature of the system is maintained at 25° C. and the humidity is 30% during the entire preparation process.

Embodiment 3

[0033] Embodiment 3: A method for forming potassium superoxide tablets, including the following steps:

[0034] Take 100g of potassium superoxide powder (particle size of 20 mesh) with an oxygen content of 31%, 14g of potassium hydroxide (particle size of 80 mesh), and 2g of copper oxychloride (particle size of 100 mesh), stir and mix uniformly to obtain a powder mixture ;

[0035] The powder mixture is put into a Φ9mm*2.7mm mold, and the powder mixture is pressed under a pressure of 90 MPa to form potassium superoxide tablets; the temperature of the system is maintained at 23° C. and the humidity is 25% during the entire preparation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com